Midco Unipower A-Series User Manual

Page 12

V5055 Valve Body with

Motorized Actuator Cont.

XIV Automatic Gas

Valve Leak Test

XV Flame Safeguard

XVI Special Equipment

■

■

■

■

Do not disassemble the valve actuator, it is not field repairable. If malfunction occurs, replace

the entire actuator.

1.

Turn off power to burner.

2.

Fully close the manual test cock (located downstream of the gas input adjuster.

3.

Remove the

1

/

8

" pipe plug from the test tap located:

a. with diaphragm valve (in one of the pipes nipples between the valve and test cocks, or

b. with motorized valve (in the bottom of the valve body on its downstream side, or in the

tee connecting the high gas pressure switch tube to the valve train.

4.

Install a pet cock in the test tap and attach a short length of

1

/

4

" flexible tubing. The open

end of the tubing should be cut at a 45° angle.

5.

Immerse the open end of the tubing to a depth of

1

/

2

" in a container of water.

6.

Open the pet cock. If bubbles appear, wait until the rate stabilizes, then count the number

appearing in ten seconds. An excess of 23 bubbles over a ten second period (approximately

.023 CFH of gas) indicates that the valve should be repaired or replaced.

7.

If there are two automatic gas valves in the valve train, check the downstream valve first and

then the upstream valve. Use the appropriate tap in one of the motorized valve bodies, or

when a diaphragm and solenoid valve are furnished, in the pipe nipple between the valves.

8.

After the test is completed, be sure to replug the test taps and fully open the test cock.

■

■

■

■

Standard Unipower burners are equipped with a Honeywell RM7895 microprocessor based

burner control, employing a flame rectification system of flame detection. Burner construction for

special codes and/or insurance requirements such as Factory Mutual or Industrial Risk Insurers (IRI)

may require alternate controls. Refer to Section XV Special Equipment. A safe start and run

control sequence is provided with instantaneous response to presence or loss of flame signal.

Flame failure response time is 3 seconds. Pilot Flame Establishing Period (PFEP) is field selectable

from 4 or 10 seconds. The RM7895 features a pre-purge time (30 seconds for On-Off, 90

seconds for 2-Step or Modulating burners) and a plug-in amplifier. An airflow circuit is also field

selectable to allow either lockout or recycle upon loss of airflow. Five LED's (light emitting diodes)

are provided to display sequence information. Refer to the Honeywell RM7895 literature for

detailed operating information, configuration requirements, testing and service.

■

■

■

■

Special Equipment, such as high-low gas pressure switches, main valve, proof of closure

switches etc., can affect the start-up and operation of the burner. Refer to your burner wiring

diagram and specific start-up instructions, as well as equipment manufacturer's literature included

with the burner for further information.

■

■

■

■

If any doubt exists concerning burner operation when special equipment is involved, contact

the installing contractor or Midco International Inc.

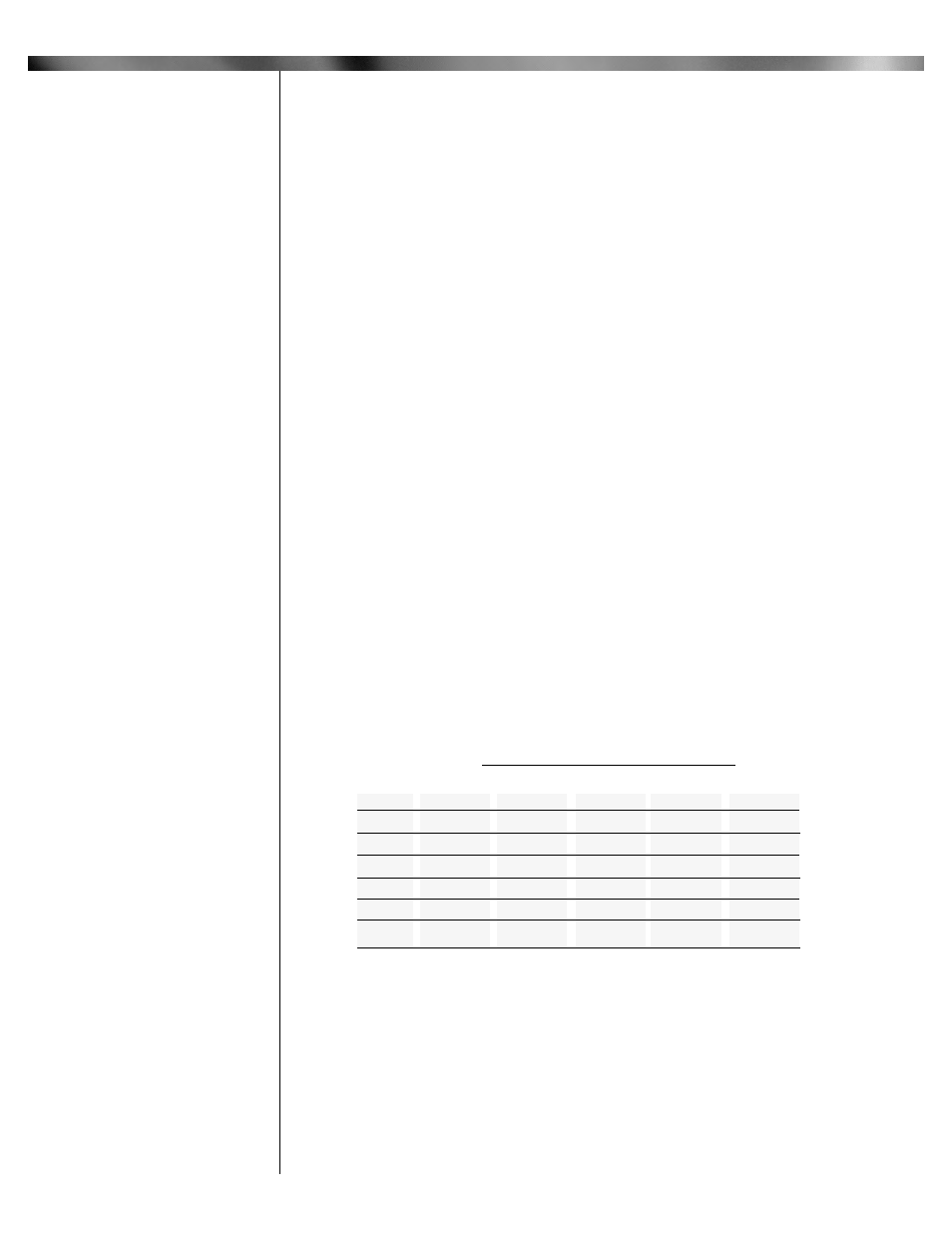

Burner

Model

0" W.C.

.25" W.C.

.50" W.C.

.75" W.C.

1.0" W.C.

A50G

A52G

A53G

A55G

A73G

A75G

A77G

1500

2000

2500

3000

4200

5000

6000

—

—

—

—

4200

5000

5800

1300

1700

2500

2800

4000

5000

5600

—

—

—

—

3850

5000

5400

*

1525

2500

2575

3650

5000

5200

Combustion Chamber Back Pressure

Table 6: Maximum Capacities at Specified Back Pressures

12