Part 1 installation – Midco J121-DS User Manual

Page 4

chamber over-fire draft, 0 to minus 0.5" W.C., a fixed damper should be installed in

the vent connector between the barometric and chimney to restrict the chimney

draft to a point within the controlling capacity of the barometric. After final setting,

the damper should be permanently fastened into position per ANSI Z223.1-latest

edition "National Fuel Gas Code", or latest edition available from American National

Standards Institute to prevent tampering.

______________________________________________________

The supply piping to the burner should branch off from the main line as close to the

source as possible (NATURAL gas meter or PROPANE tank regulator). When

branching off from an existing gas line, do not tap off the bottom of a horizontal

section. Use new black pipe and malleable fittings free from cutting and threading

burrs or defects.

Use pipe joint compound resistant to liquid petroleum gases when using either

NATURAL or PROPANE gas. Piping must comply with the local and national codes.

If the burner piping must be rearranged because of space limitations, be sure to

carry out the general configuration shown in Figure 3.

A suitable Main Gas Pressure Regulator should be installed as shown in Figures

1 or 3. Choose a regulator(s) to adjust the available gas pressure to the pressure

shown in SPECIFICATIONS, page 2.

CAUTION: The regulated gas pressures must not exceed 14" W.C. or Main

Automatic Gas Valve and Ignitor Regulator will be damaged. If excessive gas

pressure is prevalent, the regulator must be a tight shut-off type to prevent

high pressures from developing during stand-by.

For full input, refer too SPECIFICATIONS, page 2, for minimum gas pressure

required. For reduced capacities, refer to Firing Rate Curves, Table 2.

CAUTION: If gas supply pressure is below its specified range during

adjustment, an over-fire condition could result when pressure returns to

normal, particularly if the regulator adjustment screw is bottomed out.

ALWAYS confirm that at least the minimum rated pressure is being supplied

during regulator adjustments, and NEVER BOTTOM OUT regulator screw.

When selecting the burner supply piping size per Table 1, the permissible

pressure drop must be based on the pressure available at the inlet to the supply

pipe branch line when all other gas equipment fed by the same source (NATURAL

gas meter or PROPANE tank regulator) is firing at full rate. Also take into account

any other INCINOMITE burners to be attached to the same branch line.

When pressure testing the supply piping, the burner valve train must be

protected. If the test pressure is 0.5 PSIG or less, closing the Main Manual Shut-Off

Valve will suffice.

CAUTION: If the test pressure is over 0.5 PSIG, the test must be made

without any burner components connected, including Main Manual Shut-Off

Valves.

WARNING: EXPLOSION HAZARD. DO NOT USE OXYGEN FOR PRESSURE

TESTING. AN EXPLOSION COULD OCCUR DURING INITIAL START-UP.

4

Part 1 Installation

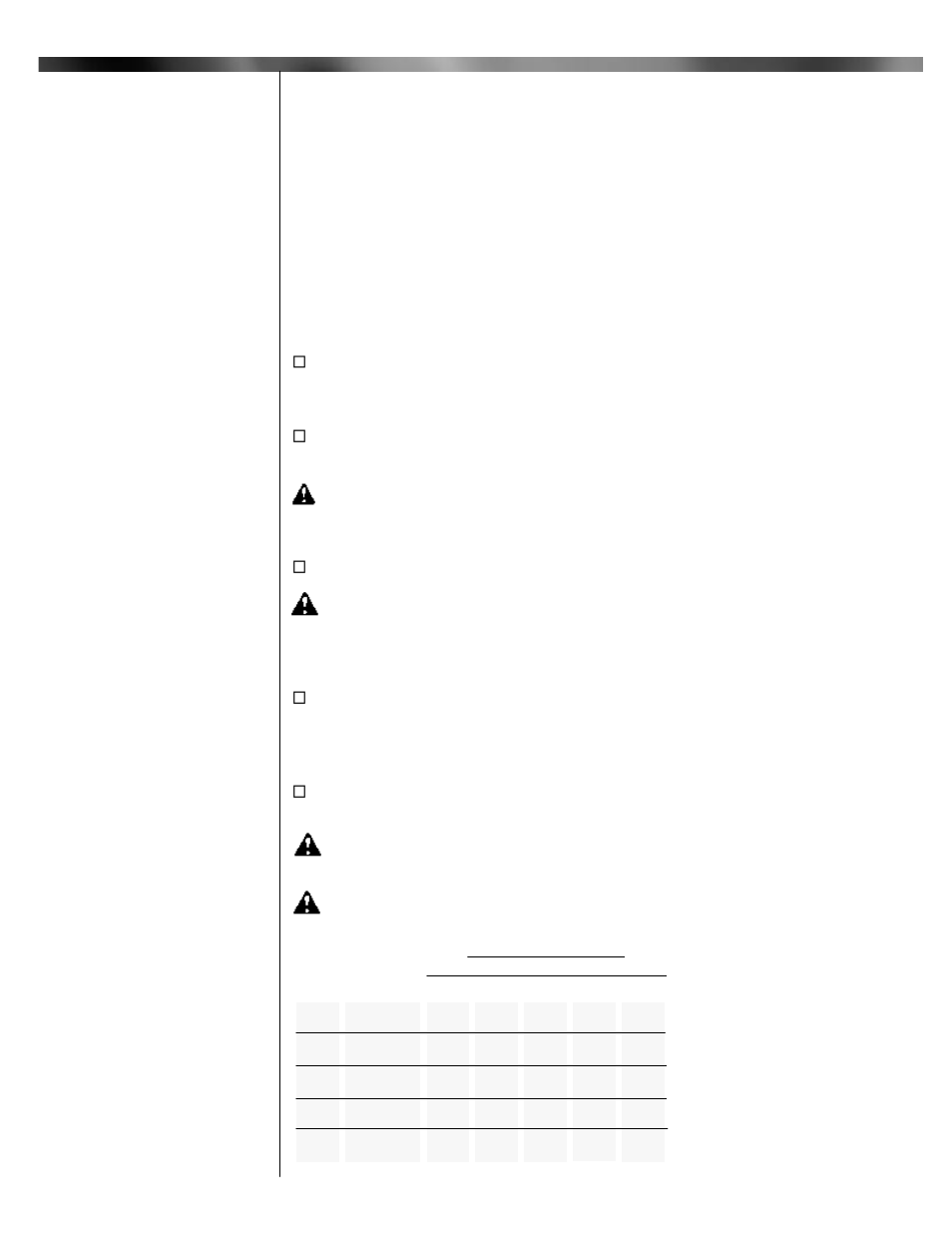

Capacities shown are for total

pressure drop of 0.3"W.C. For

higher permissible pressure

drops consult your fuel supplier.

Source: Gas Engineers

Handbook-1974

Industrial Press Inc. NY, NY

NPT

PIPE

SIZE

3/4"

1"

1 1/4 "

1 1/2"

2

275

450

520

800

800

---

---

---

---

---

200

300

350

550

730

800

800

---

---

---

130

200

245

385

500

790

760

800

800

---

100

165

195

300

400

630

610

800

800

---

---

125

150

235

300

480

460

725

800

800

TYPE

OF

GAS

Natural

Propane

Natural

Propane

Natural

Propane

Natural

Propane

Natural

Propane

APPROXIMATE CAPACITY-MBH

LENGTH OF PIPE / FEET

Table 1 Schedule 40 Pipe Capacities in MBH

10

20

40

60

100

Part 1

Installation

Continued

V Piping