Part 1 installation – Midco J121-DS User Manual

Page 2

Part 1 Installation

Specifications

1

Part 1

Installation

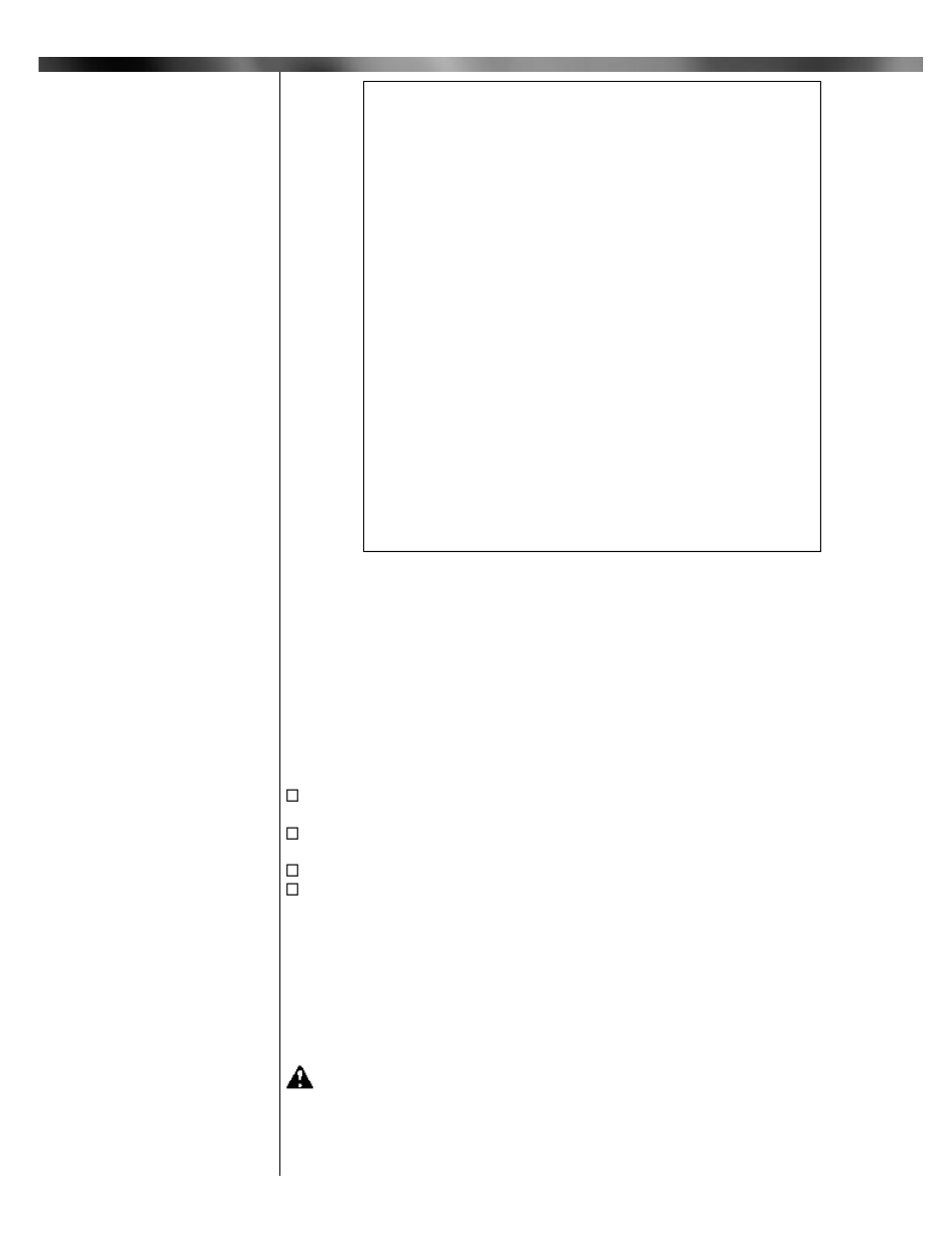

BURNER AIR DELIVERY

Approximate Air Delivery at Zero Draft….....180 SCFM

2

MINIMUM GAS PRESSURE LISTED FOR PURPOSE OF

INPUT ADJUSTMENT

(Take Pressure at Inlet Tap of Main Automatic Valve)

NATURAL………………………………………………..5.5" W.C.

PROPANE……………………………………………….8.0" W.C.

BURNER FIRING RATE (NATURAL OR PROPANE)

3

All Ratings Based on 1000 BTU/cu. ft. NATURAL, 2500 BTU/cu. ft. PROPANE at Sea Level

MINIMUM……………………………………………...100 MBH

4

MAXIMUM (With Combustion Air From Burner Only)

20% Excess Air……………………………900 MBH

0% Excess Air (stoichiometric)……..….1080 MBH

MAXIMUM (With Combustion Air From Burner Blower

and Additional Air Available in Combustion Chamber.)

NATURAL Gas 5.5" W.C. or PROPANE Gas at 11.0" W.C.

Gas Pressure at Main Automatic Valve……….1,200 MBH

ELECTRICAL SUPPLY……………………120/1/60; 4.5 amps

BURNER ON-OFF CONTROL……………Toggle Switch.

FLAME SAFETY…………………...Electronic Flame Safety

with spark ignited ignitor (pilot) and 100% shut-off.

OPTIONAL WEATHERHOOD

5

ADJUSTABLE FIRING ANGLE…………...Mounting Flange

adjustable for horizontal or 10° down firing.

NOTE: Burner components are UL recognized, CGA listed, CSA certified

and/or AGA design

certified, mounted and wired. The complete burner is fire tested.

1. Standard burners are shipped as NATURAL gas models. A kit is available for field conversion to

PROPANE gas.

2. SCFM = Standard Cubic Feet/Minute.

3. NOTE: Firing rate with combustion air from burner blower only is based on using standard air at sea

level with zero draft over-fire. De-rate burner for altitudes over 2,000 feet by 4% for each 1000 feet of

additional elevation.

4. 100 MBH = 100,000 BTU/Hr.

5. Kit is available for field installation.

2

No. 1 Waste: Primarily dry material such as paper, rags and wood. Burner normally

required only for light-off.

No. 2 Waste: Consisting of approximately equal portions, by weight of No. 1 and No.

3 waste; 70 lbs. per 100 MBH.

No. 3 Waste: Wet material such as garbage; 25lbs. per 100 MBH.

No. 4 Waste: Organic materials such as small carcasses and waste from hospital

operating rooms or pathological laboratories; 13 lbs. per 100 MBH.

NOTE: The burner input required for the secondary chamber must be determined from

the heat required to maintain the discharge temperature of the flue products as specified

by the EPA for the type of waste involved and the location of the incinerator.

______________________________________________________

Make sure that the incinerator room has sufficient ventilation to provide the necessary

combustion air for the burner fuel, the waste material and any other appliance that would

draw its air from the same enclosed area.

WARNING: Under no condition should the access to outside air be so

restricted that the maximum possible use of combustion air is inhibited. Pay

particular attention to exhaust fans that could draw air from the area and create a

negative pressure in the room.

I Primary Chamber Fuel Input

II Indoor Ventilation