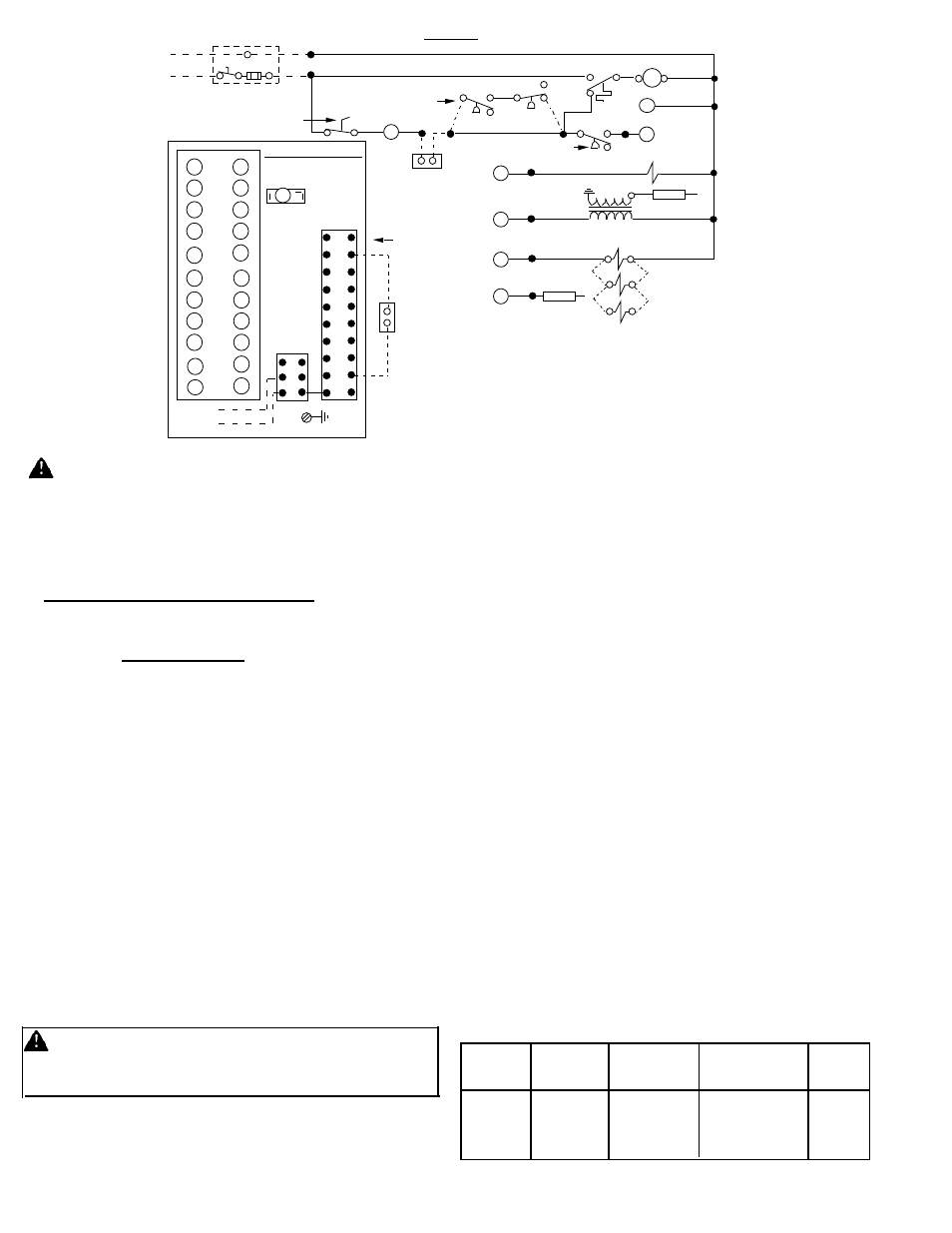

Part 1 service, Viii ignitor and regulator assembly, Figure 2 wiring diagram – Midco J121A-3 User Manual

Page 6

12. The actual NATURAL gas firing rate in BTU per hour

can be determined by timing the gas meter. Accurately

time the meter test dial for one revolution, convert to

hourly cubic feet and multiply by the BTU per cubic foot

value of your gas per formula:

Then divide by 1,000 for MBH value.

13. Start and stop the burner several times to check its

operation with the charging door open, and then with

it closed. Remove any temporary Door Open bypasses

installed in Step 6.

14. Test operation of any auxiliary operating and/or limit

controls.

15. Load incinerator and make trial run. Confirm that the

incineration chamber pressure stays within the range of

0 to minus 0.5"W.C. for Model J81A-3 and 0 to minus

1.0” W.C. for Model J121A-3.

16.

WARNING: When the incinerator is located

inside a building and a draft control is used, check

that there is no spillage of flue products from the draft

control.

17. To shut off: Turn Burner Switch or Timer off and close

Main Manual Shut -Off Valve

PART 1

SERVICE

WARNING: BE SURE THAT THE MANUAL VALVE AND

BURNER DISCONNECT SWITCH ARE TURNED OFF BEFORE

ANY PARTS ARE REMOVED FOR SERVICE.

VIII

IGNITOR AND REGULATOR ASSEMBLY

The Ignitor and Regulator Assembly is removed as a unit.

Disconnect the ignitor gas line and electrode wires, remove

the two mounting screws and pull out the assembly.

■

When the ignitor gas pressure is in the proper range (see

Table 4) and the electrodes are adjusted to the dimensions

shown in Figure 5, any ignition problems are usually

caused by lint, dust, corrosion, cracked electrode

insulators, foreign matter in the blast tube or deterioration of

ignitor ports in Retention Plate.

■

Ignitor trouble will be evidenced by failure of main burner

ignition. It may also be indicated by poor or erratic relay

response which cannot be remedied by ignitor gas

adjustment, or it may cause frequent Flame Safeguard

lockout. Check for dirt in the ignitor air and mixture

passageways and check for obstructions in the ignitor

ports. Also check electrode adjustments (see Figure 5).

Replace any severely burned parts.

■

Proper operation of the flame sensor rod can be checked

by measuring the flame signal. With the Flame Safeguard

energized and only the ignitor burning, a good reading

should run steady 2 or more volts DC.

■

When servicing, clean the Ignitor Retention Plate ports

and blow out the internal air and gas passages. Clean the

Electrode Insulators and check them for hairline cracks.

Also check the electrode ends and the Ground Barrier for

serious corrosion or loss of metal. Replace any defective

parts.

■

Make sure that there is no debris in the Blast Tube that

could short out the Spark or Flame Electrode.

■

Clean the Ignitor Gas Orifice in Tee Orifice Fitting (see

Figure 5) and check that the orifice size is correct per Table

4.

TABLE 4

Ignitor Firing Rate

Q7800 BASE FOR

RM7890 FLAME

SAFEGUARD

G

5

20

21

6

7

8

F

3

4

9

10

19

18

17

16

22

15

14

13

L2

12

L2 3 4 5 6 7 8 9 10 11

NEUTRAL

120/1/60

HOT

4

5

6

1

2

3

MAIN GAS VALVE

OPTIONAL

REDUNDANT VALVE

OPTIONAL VENT

VALVE

BLOWER MOTOR

NO

NC

C

SAFETY & OPERATING

CONTROLS

FLAME ROD

SPARK ROD

3 2 1

THERMAL

SWITCH

THERMAL SWITCH

OPTIONAL HI-LO GAS PRESSURE

SWITCH. IF USED, REMOVE

JUMPER 3-4

L2

L1

BK

3

10

Y

3

4

R/W

1

2

3

8

10

9

F

6

7

8

W(BK)

IGNITOR GAS VALVE

BR

BL

BL

BL/W

BK(W)

O

9

Y/BK

BK

W

L2

6

HOT

120/1/60

NEUTRAL

SCHEMATIC

FUSED DISCONNECT

TERMINAL STRIP

SAFETY & OPERATING

CONTROLS

COMPONENT LAYOUT

Y/W

SWITCH OR TIMER

(LINE VOLTAGE)

(LINE VOLTAGE)

J81A-3 MOTOR END SWITCH

J121A-3 BLOWER AIR SWITCH

5

R

BL/W

Y/W

SPARK GENERATOR

R/BK

L2

L1

L

R/BK

IF NOT USED JUMPER

10 TO 3

FIGURE 2

Wiring Diagram

CAUTION: If a remote switch or timer is installed, remove or turn off the burner switch when using the remote control

TYPE

OF

GAS

NATURAL

PROPANE

NATURAL

PROPANE

IGNITOR

GAS

RATE

6 MBH

7 MBH

13 MBH

15 MBH

IGNITOR

ORIFICE

DIAMETER

.052 (#55 Dr.)

.042 (#58 Dr.)

.070 (# 50 Dr.)

.063 (#52 Dr.)

RECOMMENDED

IGNITOR GAS

PRESSURE

3.5 "W.C.

-6-

3600 x Test Dial Size x BTU Value

No. of Seconds for One Rev. Test Dial

= BTU/Hr.

Example: 3600 x 1 x 1000*

20

*Approximate BTU value.

=180,000 BTU/ Hr. = 180 MBH

MODEL

J81A-3

J121A-3