Velectrical, Vi piping, Type of gas – Midco RE32 User Manual

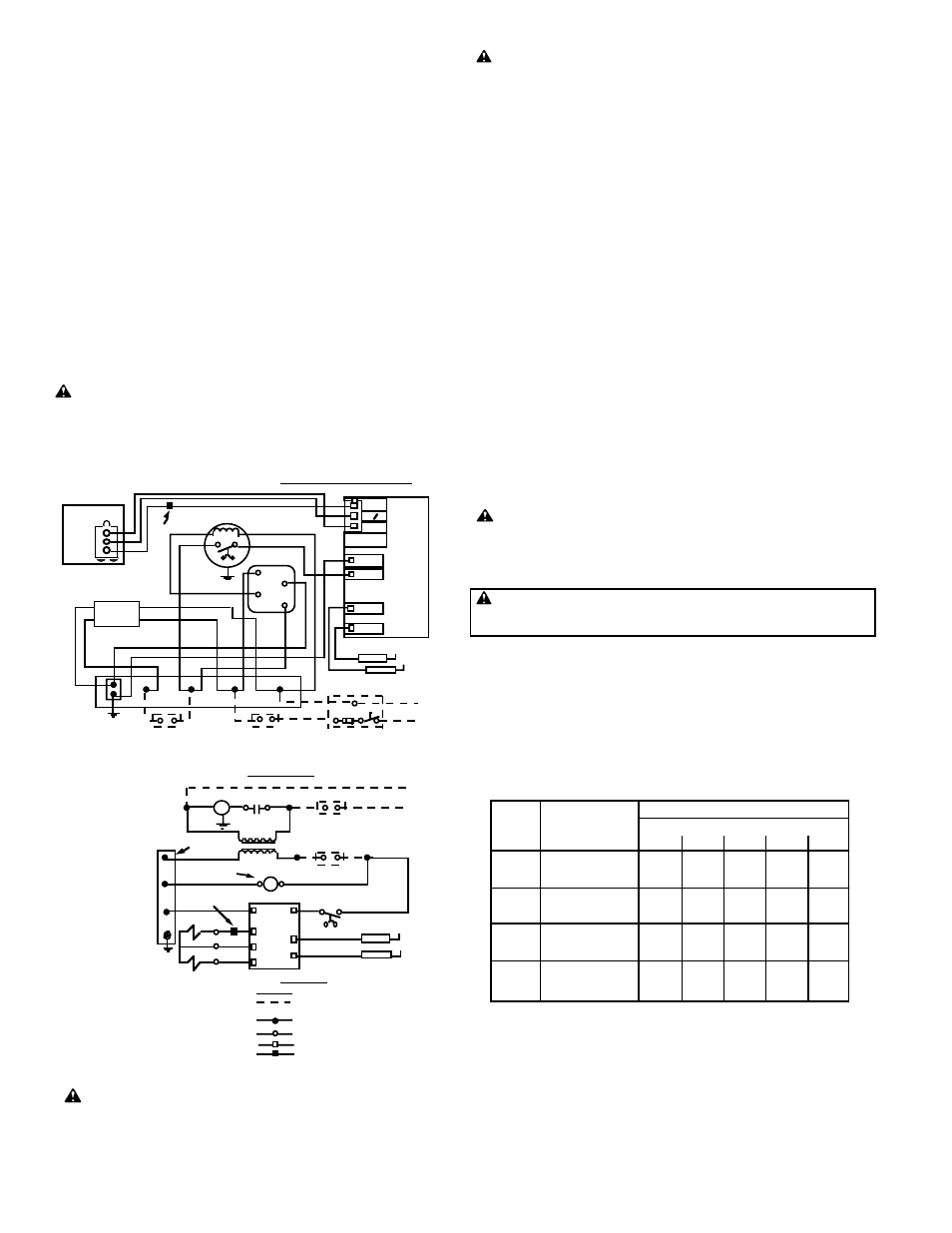

Page 4: Table 2: supply pipe capacities in mbh, Figure 6 wiring diagram pipe size

-4-

V

ELECTRICAL

Installation wiring and grounding of the burner must conform to

local codes, or, in their absence in the United States to

National Electric Code, ANSI/NFPA No. 70-1 latest edition; in

Canada, to Canadian Electrical Code Part 1, CSA Standard

C22.1.

■

Use 14 gage copper wire for line voltage wiring. Be sure to

hook up to permanently live circuit. Provide a fused on-off dis-

connect switch carrying a minimum 3 amp fuse.

■

The frame of the burner should be well grounded. A terminal

is provided on the strip for positive grounding.

■

Confirm that the polarity is correct -- hot wire to strip terminal

1, neutral 2 -- and that the neutral line is not subject to induced

low voltage (check 2 to earth ground) from other equipment, as

that can cause the flame safeguard to malfunction.

■

Each installation must include suitable limit control(s).

Existing oil burner combination operating and limit controls are

normally NOT SUITABLE for gas burner use.

■

Set the thermostat heat anticipator for the total current draw

handled by the thermostat. The current draw of the Economite

24V operating circuit is 0.9 amps.

CAUTION: Label all wires prior to disconnection when

servicing controls. Wiring errors can cause improper

and dangerous operation. Verify proper operation after

servicing

.

10

130

200

275

300

300

TYPE OF

GAS

NATURAL

PROPANE

NATURAL

PROPANE

NATURAL

PROPANE

NATURAL

PROPANE

VI

PIPING

CAUTION: The available gas pressure should be within

the limits shown in the SPECIFICATIONS section.

Excessive pressure will damage Combination Valve and

Regulator. If the supply pressure exceeds the 14.0" W.C.

maximum, a suitable intermediate main regulator rated for

main and pilot loads must be installed ahead of the Main

Manual Shut-Off Valve shown in Figure 7.

■

The burner gas supply piping should branch off from the

main line as close to the gas meter as possible. Do not connect

to the bottom of a horizontal section. Use new black pipe and

malleable fittings free of cutting and threading burrs or defects.

■

Provide a sediment trap, union and 1/8" pressure tap in

piping close to burner as shown in Figure 7.

■

Use pipe joint compound approved for use with Liquid

Petroleum Gases.

■

Piping must comply with local codes.

■

To obtain the maximum firing rate of 300 MBH, the gas

supply piping must be sized to provide a minimum of 4.0" W.C.

pressure to the inlet of the combination valve when the burner

and all other gas utilization equipment are on. For a firing rate

of 225 MBH or less, 3.5" W.C. inlet pressure is sufficient.

■

When selecting the burner supply pipe size per Table 2, the

permissible pressure drop must be based on the pressure

available at the inlet to the supply pipe branch line when all

other gas utilization equipment is on.

NOTE: If there is more than 1.0" W.C. differential in the inlet

pressure to the burner compared to when all other gas

utilization equipment is off, refer to Section IX, last paragraph.

CAUTION: Because it is difficult to accurately control

pressure during supply pipe leak test, it is recommended

that the Combination Valve be disconnected. Exposing the

Combination Valve to a pressure over 1/2 (14" W.C.) PSIG

will damage the valve and void all warranties.

DANGER: Explosion hazard. Do not use oxygen for

pressure testing. An explosion could occur during initial

start-up.

■

If the burner piping must be rearranged because of space

limitations, be sure to carry out the general arrangement shown

in Figure 7. Install the combination valve in any position except

up-side down.

■

When the burner is installed in the vestibule of jacketed

equipment, it is recommended that the combination valve be

left adjacent to the burner within the vestibule. Install the Main

Manual Shut-Off Valve in the piping outside the jacket of the

equipment.

TABLE 2: Supply Pipe Capacities in MBH

Capacities shown are for a total pressure drop of 0.3" W.C. For

higher permissible pressure drops, consult your fuel supplier.

Source: Gas Engineers Handbook-1974

CAUTION: Do not add any power consuming devices in

the low voltage circuit as it could overload the transformer.

Do not use Motor Relay to operate any external devices as

the extra load could damage the relay contacts.

NOTE: If any of the original wiring as supplied with the

conversion burner must be replaced, it must be replaced with

type TFF wire or its equivalent.

FIGURE 6

Wiring Diagram

PIPE

SIZE

1

Ъ

2

3

Ъ

4

1

1

1

Ъ

4

20

90

145

190

300

300

40

60

100

130

200

245

300

300

60

50

80

105

165

195

300

300

100

60

80

125

150

235

300

300

APPROX. CAPACITY-MBH

LENGTH OF PIPE

MV

PV

MV

PV

MV PV

GND

BURNER

24V

GND

24V

SENSE

MOTOR WITH INTERNAL

INTERLOCK SWITCH

COMBINATION

VALVE

SCHEMATIC

CONNECTION DIAGRAM

2

4

1

3

MOTOR RELAY

T

T

1

2

GND

Y

BK

BL(Y)

W(BK)

TRANSFORMER

NEUTRAL

120/1/60

HOT

THERMOSTAT OR 24V OPERATING

CONTROL. IF NOT USED, JUMPER T-T

SERIES CONNECT ALL 120V OPERATING

AND/OR LIMIT CONTROLS

FUSED DISCONNECT

BL

TERMINAL

STRIP

2

1

NEUTRAL

MOTOR

BK(W)

BK

M I

4

2

HOT

120 V CONTROLS

120/1/60

W(BK)

BK

Y

BL(Y)

T(LEFT)

T(RIGHT)

24V

THERMOSTAT OR 24V CONTROL

IF NOT USED, JUMPER T-T

M

1

3

MOTOR RELAY

SPST N.O.

BL

Y

R(Y)

INTERLOCK SWITCH

R(Y)

GROUND

BAR

BK

LEGEND

Y

24V

GND

24V

SENSE

SPARK

BK

SPARK ROD

SPARK ELECTRODE

SENSOR ROD

BL

BR

Y

BK

BK

R(Y)

R(Y)

W(BK)

(NOT USED)

SPARK

BK

WIRING AND

COMPONENTS:

TERMINALS:

Y

MV/PV

GND

S8600 ELECTRONIC CONTROL

MV

PV

MV

PV

Y

BL

BR

MV/PV

MV/PV

SENSE ROD

BR

Y

BL

Y

BL

BY MIDCO

BY INSTALLER

TERMINAL STRIP

COMPONENT

ELECTRONIC CONTROL

SPLICE

SPLICE

SPLICE