Part 1 installation, Specifications, Iii combustion chamber – Midco RE32 User Manual

Page 2: I ventilation, Ii preparation of the gas utilization equipment

around door frames, to prevent leakage into or out of the

combustion chamber.

■

The access or firing door should open easily to relieve

pressure. If positive latches exist, they should be modified to

permit easy opening; a spring loaded door holder is

recommended.

■

On all boilers, make certain the pressure relief safety valve is

in good operating condition.

III COMBUSTION CHAMBER

A combustion chamber liner is normally required to protect

non-heat transfer surfaces and to provide a radiant bed for

rapid heat transfer to the primary surfaces of the heat

exchanger. In most cases an existing oil burner combustion

chamber liner can be used, if in good condition.

■

In the case of wet base boilers, where the entire combustion

chamber is comprised of heat exchange surfaces and no

combustion chamber liner was provided for oil firing, a liner is

usually not required for the ECONOMITE. However, a liner or

target wall may be necessary if the combustion chamber is

unusually short, in order to avoid excess flame contact on the

heat exchanger walls or flueways.

■

If a built up combustion liner is required, use 2300oF

minimum insulating material.

■

The opening in the combustion chamber must fit the burner

tube. If an existing chamber with an oversized opening is to be

used, fill the remaining space around the tube with refractory

material and seal air tight.

NOTE: In no case should the burner tube be allowed to extend

into the chamber proper; it must be set flush to 1/4" short of the

inside surface, because high combustion chamber

temperatures will cause premature pilot deterioration.

■

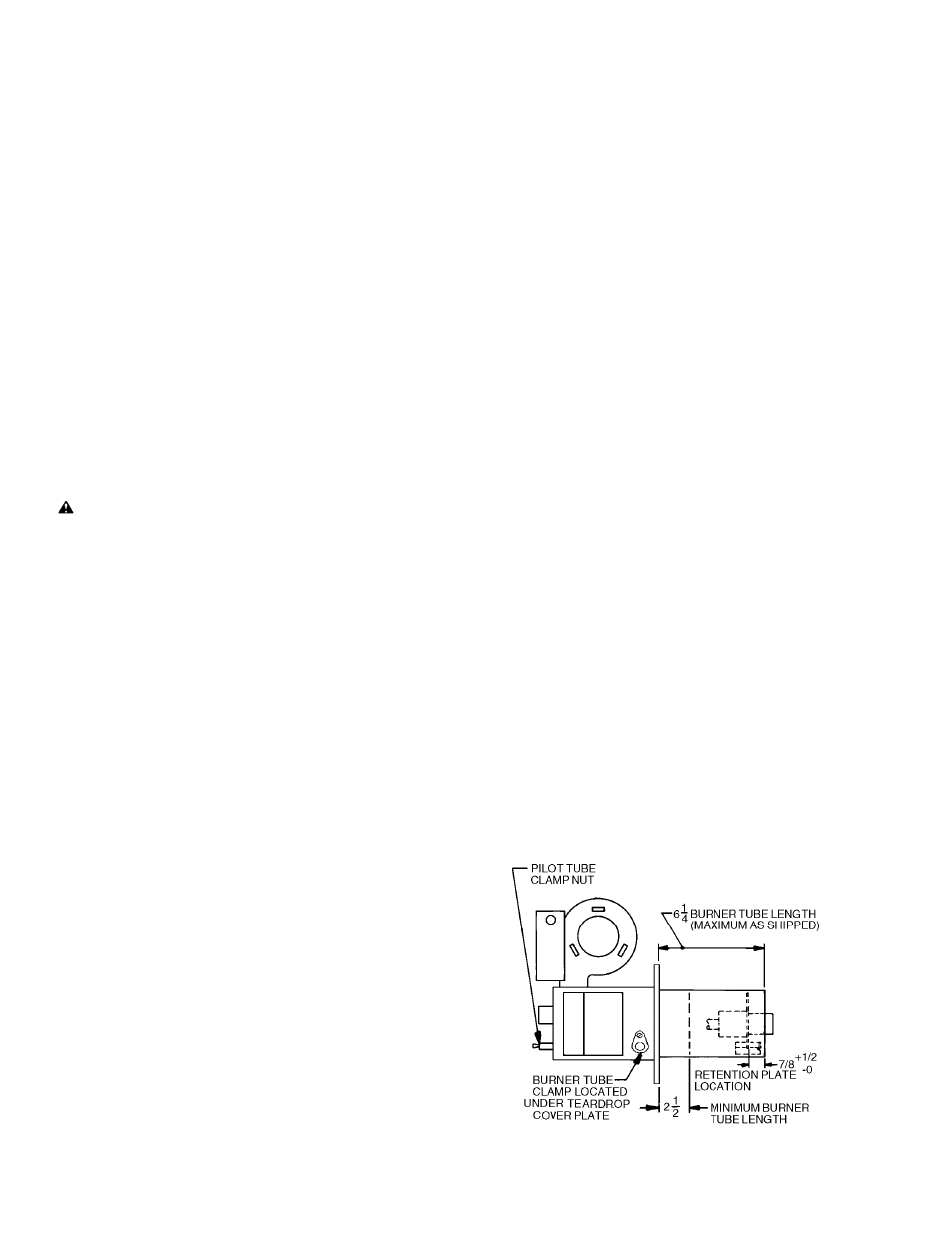

Burners are shipped with the burner tube at its fully extended

length of 6

1/4

inches. To reduce the tube length, complete the

following steps (see Figure 1):

1.

Uncover the Burner Tube Clamp access port located on the

lower right side of the burner box (under motor),

adjacent to the mounting flange.

2.

Turn the exposed screw counter-clockwise to loosen

the Burner Tube Clamp.

3.

Turn the Pilot Tube Clamp Nut (see Figure 1)

counterclockwise, to loosen the Pilot Tube.

4.

Push Burner Tube in to desired length and tighten

Burner Tube Clamp and recover access port.

5.

Locate the retention plate at least 7/8 inch but not more

than 1

3/8

inch from the end of the burner tube and tighten

the Pilot Tube Clamp Nut.

6.

Cut the Pilot Tube to the appropriate length and

reattach tube fitting using compression sleeve supplied in

spud-bag.

FIGURE 1

Burner Tube Adjustment

-2-

SPECIFICATIONS

NATURAL or PROPANE Gas

AIR DELIVERY

(Approx. Air Delivery at Zero Draft)

.....62SCFM*

MAXIMUM FIRING RATE**................................300MBH***

MINIMUM FIRING RATE**...................................50MBH***

TUBE DIAMETER................................................4 inches

TUBE LENGTH......................................2

1/2

- 6

1/4

inches

MINIMUM COMBUSTION CHAMBER SIZE

300 MBH...................................7" W x 11" L or 10" dia.

50 MBH.....................................6" W x 10" L or 9" dia.

GAS PRESSURE REQUIRED

NATURAL..........................................4.0" to 14.0"W.C.

PROPANE.........................................4.0" to 14.0"W.C.

STANDARD VOLTAGE..........120 Volts.............60 Cycle

PILOT SAFETY.........................Electronic, 100% shut-off

MAIN AUTOMATIC VALVE...........4 Function Redundant

*SCFM = Standard Cubic Feet/Minute

**All Ratings Based on 1000 BTU/Cu. Ft. NATURAL, 2500

BTU/Cu. Ft. PROPANE at Sea Level Derate burner for

altitudes over 2,000 feet by 4% for each 1,000 feet above

sea level

***1 MBH = 1,000 BTU/Hr.

One gallon fuel oil = 140,000 BTU/Hr.

PART 1

INSTALLATION

CAUTION: The ECONOMITE RE32 is not intended for

outdoor installation and must be protected from excessive

moisture. Provide adequate clearance for service and

proper operation.

I VENTILATION

If the former automatic oil burner gave trouble-free operation, it

is probable that the gas utilization equipment area has sufficient

infiltration of air for combustion and dilution of flue gas.

Nevertheless, the area must be checked:

■

Open basement or utility areas of normal construction,

without storm windows or tight doors, will generally allow

sufficient air infiltration. However, if the gas utilization

equipment is located in a tight or separate room, ventilation to

an open area as described above will be required. Install two

permanently open grilles, each sized on the basis of one

square inch free area per 1,000 BTU (but not less than 100

square inches) of the total input ratings of all gas utilization

equipment in the combined space. One grille should be located

within 12 inches of the ceiling, the other within 12 inches of the

floor.

■

If the gas utilization equipment is located in an area of

unusually tight construction, or if an exhaust fan, kitchen

ventilation system, clothes dryer and/or fireplace is installed in

the building, provision must be made for an outside air supply

near the gas utilization equipment area. Install permanently

open grilles sized at not less than one square inch free area per

4,000 BTU of burner input. When ventilating through horizontal

ducts, grilles should be sized at not less than one square inch

free area per 2,000 BTU of burner input. In any case, the

minimum dimension of rectangular air ducts shall not be less

than 3 inches.

■

In Canada, for detailed ventilation requirements, refer to

standard CAN/CGA 1-B149.1 or .2 and/or local codes.

II PREPARATION OF THE GAS

UTILIZATION EQUIPMENT

■

Clean the gas utilization equipment heat exchanger interior,

combustion chamber and flue connections. Remove all

adhering tars, scale, dirt and soot. Inspect equipment for actual

leaks and/or potential leaks.

■

Cement all joints, including those in the equipment base and