Part 1 installation – Midco Economite RE4400B / RE4400BA User Manual

Page 3

Clean the gas utilization equipment combustion chamber, heat exchanger interior, and flue

connections. Remove all adhering tars, scale, dirt and soot. Inspect for actual or potential

leaks.

Cement all joints, including those in the heating appliance base and around the door

frames, to prevent leakage into, or out of the combustion chamber.

The access or firing door should open easily to relieve pressure. If positive latches exist,

they should be modified to permit easy opening; a spring loaded door holder is

recommended.

On all boilers, make certain the pressure relief safety valve is in good operating condition.

____________________________________________

A combustion chamber liner is normally required to protect non-heat transfer surfaces and to

provide a radiant bed for rapid heat transfer to the primary surfaces of the heat exchanger.

In most cases the existing chamber liner can be used, if in good condition.

In the case of wet base boilers, where the entire firing chamber is comprised of heat

exchange surfaces and no chamber liner was provided for oil firing, a liner is usually not

required for the ECONOMITE. However, a liner or target wall may be necessary if the firing

chamber is unusually short, in order to avoid excess flame contact on the heat exchanger

walls or flueways.

If a built up chamber liner is required, use 2,300°F minimum insulating material.

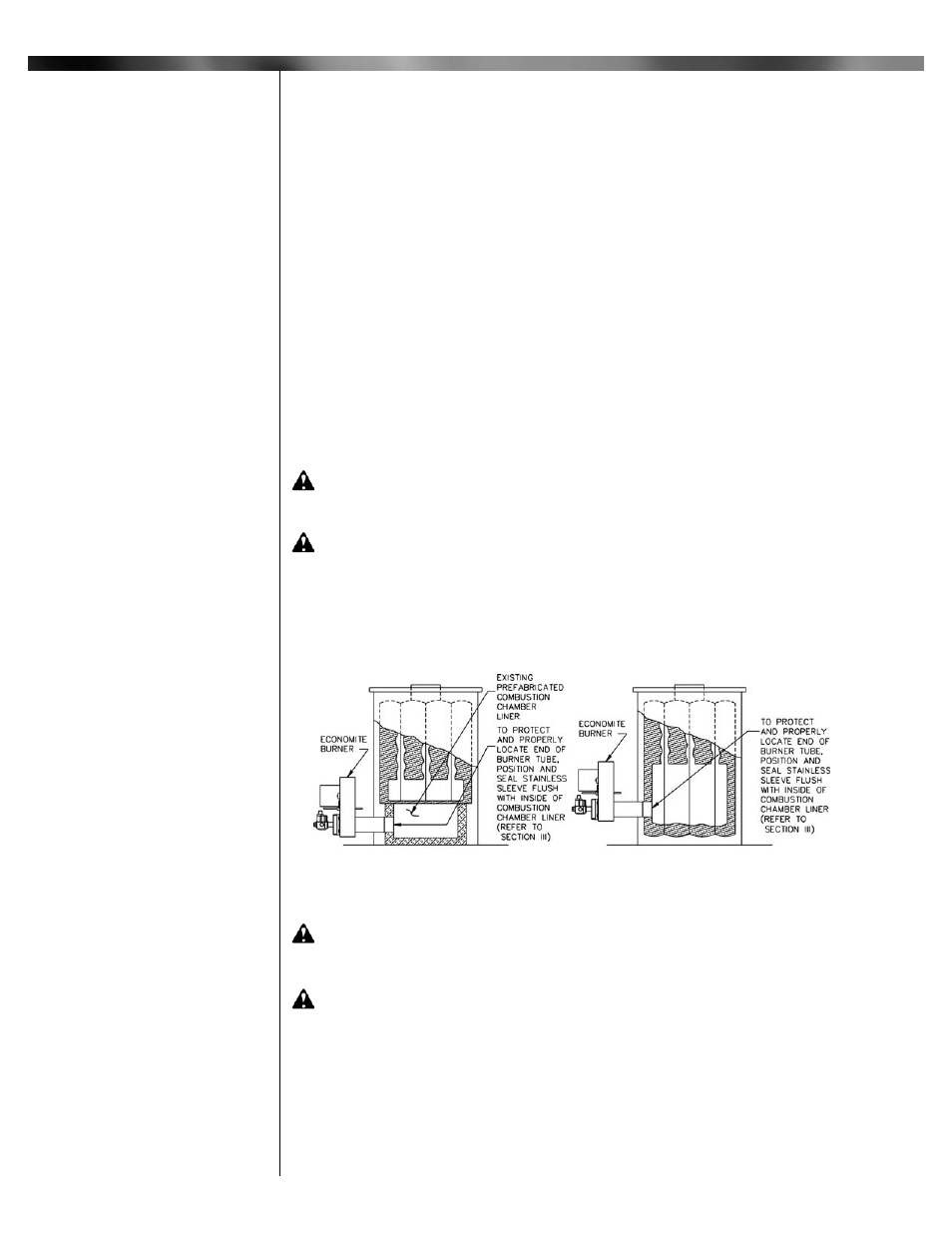

The burner tube, or the stainless steel sleeve that is included with the burner, must be

sealed air tight into the combustion chamber opening with refractory material. The sleeve is

preferred as it is designed to properly locate the end of the tube relative to the inside wall of

the combustion chamber, and to permit burner removal without breaking the seal.

CAUTION: In no case should the burner tube be allowed to extend into the

chamber proper; it must be set at least 1" short of the inside surface because high

combustion chamber temperatures will cause premature pilot, electrode, burner tube

and sleeve deterioration.

WARNING: BURNER MUST BE MOUNTED IN ORIENTATION SHOWN IN

FIGURES 1 AND 2. ANY OTHER MOUNTINGS MAY CAUSE A DANGEROUS

CONDITION, AND WILL VOID BURNER WARRANTY AND AGENCY APPROVALS. NON-

STANDARD ARRANGEMENTS MAY BE AVAILABLE FOR SOME MODELS. CONSULT

FACTORY FOR DETAILS IF REQUIRED.

Before permanently setting the burner in place, check that the main burner and pilot ports

are free of foreign materials, and also that the spark electrode assembly has not been

damaged or displaced. See Figures 7A and 7B.

____________________________________________

WARNING: The chimney shall be inspected for unsafe conditions such as

deteriorated masonry and excessive soot or other blockage or potential blockage.

Installation must conform with local codes or in the absence of local codes with NFPA,

ANSI Z223.1 latest edition.

WARNING: The vent connector shall not be connected to a chimney already

venting solid fuel burning equipment, an incinerator or an open fireplace.

The Vent Connector shall be made of non-combustible, corrosion resistant material

capable of withstanding the vent gas temperature produced by the gas utilization equipment

and of sufficient thickness to withstand physical damage.

The Vent Connector shall be as short as possible. The entire length shall be readily

accessible for inspection, cleaning, and replacement.

The length of horizontal uninsulated Vent Connector between the chimney and a single

gas utilization equipment shall not exceed 75% of the the height of the chimney above the

connector, or 100% if the Vent Connector is insulated.

3

Part 1

Installation

Continued

Part 1 Installation

II

Preparation of

the Gas Utilization

Equipment

III

Combustion

Chamber

IV

Chimney, Vent

Connector and

Draft Control

Figure 1: Dry Base Boiler with Combustion

Chamber Liner (Warm Air Furnace

Construction is Similar)

Figure 2: Wet Base Boiler with Unlined

Combustion Chamber