Part 2 service – Midco Economite RE4400DS User Manual

Page 9

flue gas samples and temperature immediately ahead of the draft control.

A.

The flue gas temperature should be above 325°F but not exceeding 550°F.

Excessive flue gas temperatures will result in low efficiencies. Low flue gas

temperature may cause excessive condensation. Reset gas input, if necessary, to

adjust stack temperature.

B.

Make the final setting of the combustion air shutter by checking the flue gases

with an ORSAT or similar combustion testing instrument. The carbon monoxide

content should conform to local codes, or in their absence, to the level specified

in the United States or Canadian Standard referenced on the front cover of this

manual; and the carbon dioxide content should be approximately 9.5% for

NATURAL or 12% for propane , or within the limits prescribed by local codes.

12. Check the draft control to make sure there is no spillage of flue products into the room.

13. FILL OUT THE INSTALLATION ADJUSTMENT DATA TAG and affix to the burner or

gas utilization equipment.

NOTE: For subsequent normal starting and shut off procedure, refer to CONSUMER

INSTRUCTIONS, located in part 3 of this manual,or to the instruction plate mounted

on the burner.

____________________________

DANGER: Do not tamper with the unit or controls. If trouble occurs contact

the installing contractor, service agency, or fuel supplier. See front cover.

DANGER: Be sure that the main Shut-Off Valve is closed and the burner

power supply is turned off before removing any parts for service.

CAUTION: Cover plates, guards, and enclosures must be maintained in

place at all times except during maintenance and service.

____________________________

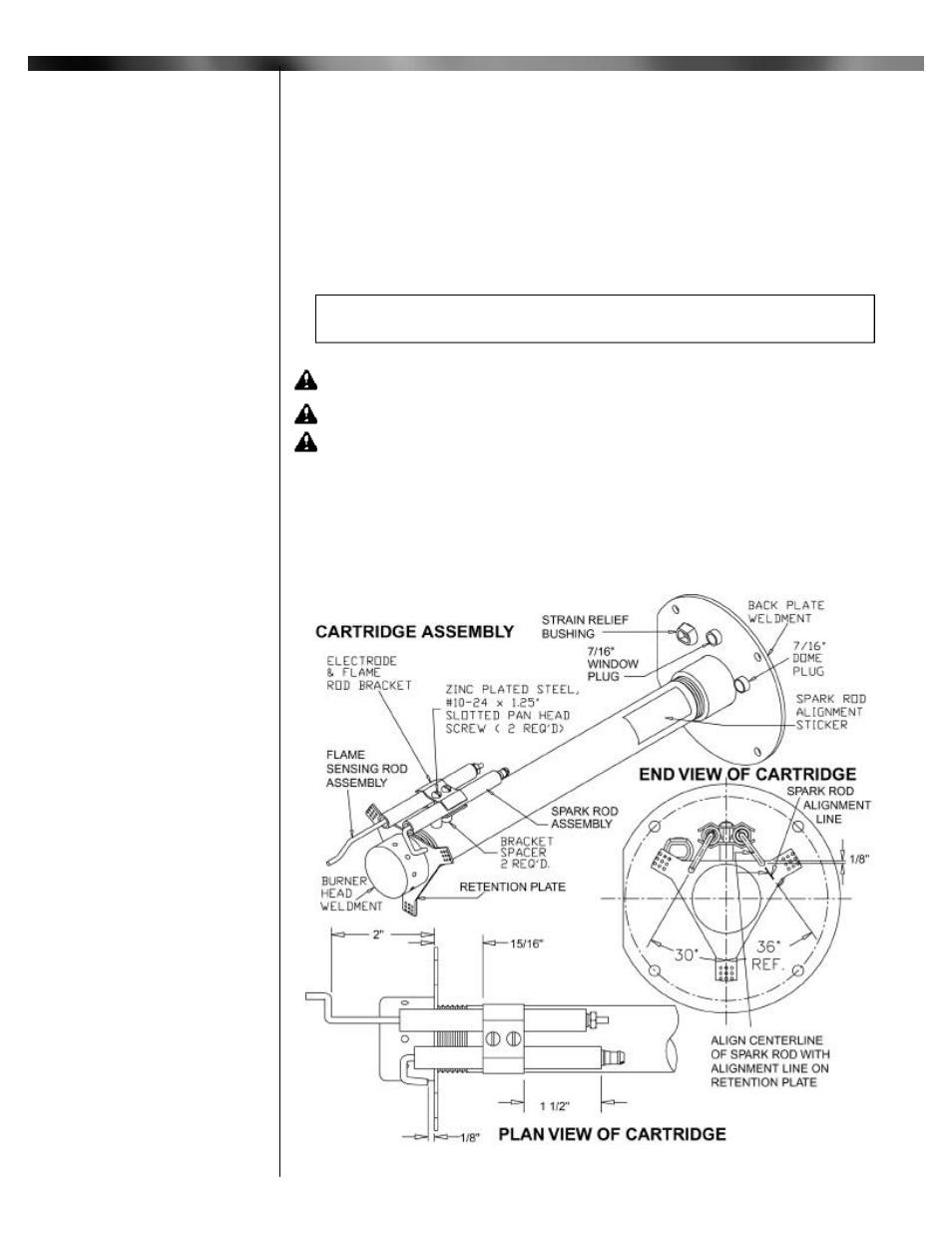

? The flame sensing rod must be positioned as shown in Figures 7A and 7B so that the

Electronic Control will detect a proper flame.

? Both the spark and flame rods are current carrying conductors and, along with their

connecting wires, must be kept free of contact with conductive metal parts of the burner. Rod

insulators and wire insulators should be clean, dry and free of cracks.

9

Part 2

Service

Part 2 Service

VIII

Initial Start-

up /Adjustment

Continued

Figure 7B: General Assembly for the RE4400DSA

Part 1

Installation Continued

IX

Electrodes