Part 1 installation, Part 1 installation continued, Vi piping continued – Midco Economite RE4400DS User Manual

Page 6

6

? When the burner is installed in the vestibule of jacketed equipment, it is recommended

that the Automatic Safety Shut-Off Valves be left adjacent to the burner within the vestibule

and the Main Manual Shut-Off Valve be installed outside.

? Run full size pipe or tubing from regulator vent openings to outside of building. Provide no

traps in the vent lines and terminate away from all doors and windows; also make provisions

for keeping rain and foreign objects from entering the vent piping.

? When high supply gas pressure is encountered, as in the case in many industrial plants,

the gas line size can be reduced to allow for a greater pressure drop; however, the size must

be sufficient to deliver burner rating pressure.

CAUTION: High gas pressure supply lines require the proper pressure

reducing regulators. Install a high pressure regulator of the Tight Shut-Off type, sized

for main gas input, upstream of the low pressure regulators.

? The high pressure regulators must be adjustable to 14" W.C. outlet pressure.

? When the gas supply line is about to be put into service it must be tested to insure that it

is gas tight. Use air or inert gas under pressure and test with soap and water to locate leaks.

? Before gas is turned onto the system, a check must be made to see that there are no open

fittings and to make sure the burner main valve is closed.

? After checking for leaks, purge the gas line up to the burner inlet. Purging the air from the

gas supply line at this step will expedite the first light-off.

NOTE: If there is more than 1.0" W.C. differential in the inlet pressure to the burner

compared to when all other gas utilization equipment are off, refer to Section VII.

____________________________

Part 1

Installation Continued

Part 1 Installation

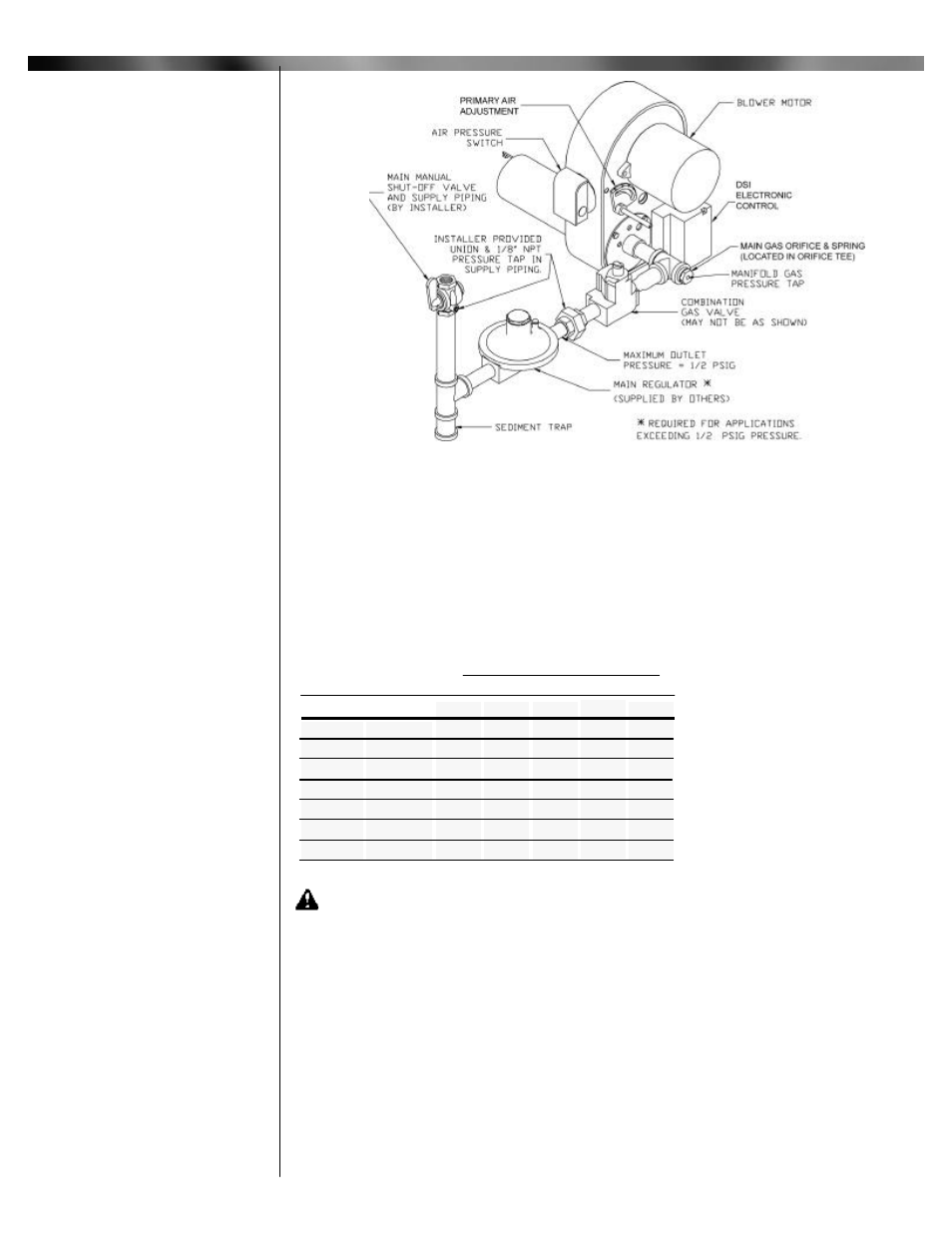

Figure 6: Piping Diagram

Natural Gas capacities

shown are for a total

pressure drop of 0.3"W.C.

For 0.5"W.C. pressure drop,

multiply capacity shown by

1.3. Propane capacities

shown are for a total

pressure drop of 0.5”W.C.

For higher permissible

pressure drops, consult

your gas supplier.

Table 2: Schedule 40 NPT

Pipe-Capacity Chart

10

200

590

400

40

275

200

500

450

650

75

190

150

360

325

475

20

150

400

275

Pipe

Size

3/4

3/4

1

1

1 1/4

1 1/4

1 1/2

Natural

Propane

Natural

Propane

Natural

Propane

Natural

100

160

300

275

630

400

Approximate Capacity -MBH

Pipe Length

Type

of Gas

VI

Piping

Continued