Part 1 installation, Specifications – Midco Economite RE4400DS User Manual

Page 2

Part 1 Installation

Specifications

1

The ECONOMITE Model RE 4400DS and RE4400DSA burners with direct spark ignition

are adaptable to most gas utilization equipment, including furnaces and boilers. Power

burner design makes them perfectly suited for oil burner replacement, including rooftop and

industrial applications.

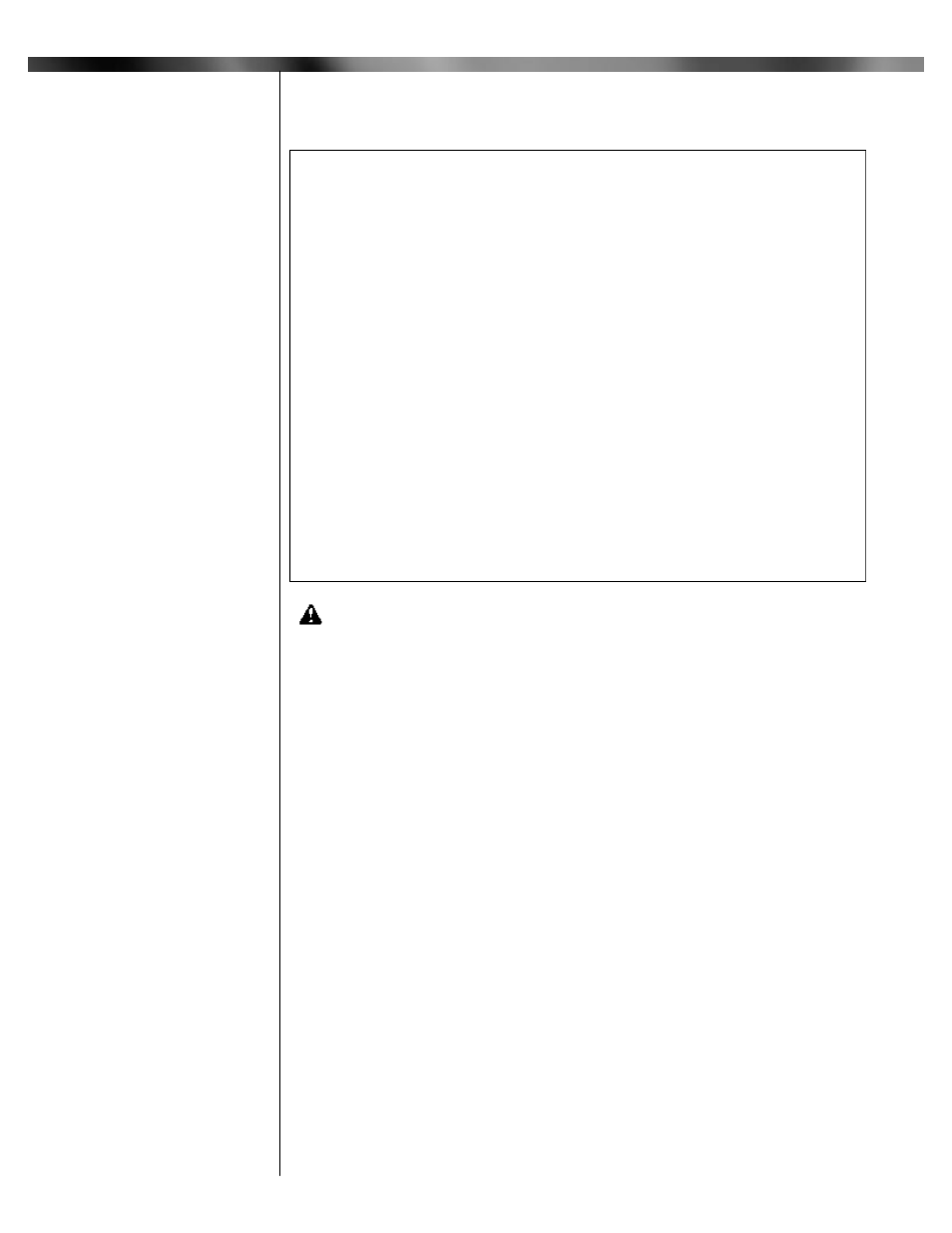

AIR DELIVERY (Approximate Air Delivery at Zero Draft)

R E 4 4 0 0 D S a n d R E 4 4 0 0 D S A ..... 125 SCFM

2

FIRING RATE (NATURAL OR PROPANE )

3

RE4400DS & RE4400DSA

MAXIMUM MBH

4

400

MINIMUM MBH

4

132

GAS SUPPLY PRESSURE REQUIRED

NATURAL ..............................................

7.0" to 14.0" W.C.

PROPANE .............................................

5.0" TO 14.0" W.C.

TUBE DIAMETER........................................................

4"

TUBE LENGTH............................................................

9"

RECOMMENDED COMBUSTION CHAMBER SIZE (AT MAX. BTU/HR)

RE4400DS & RE4400DSA

WIDTH

10"

LENGTH

16.5"

ELECTRICAL SUPPLY......................................120 VAC...........60 Hertz

5

ELECTRONIC CONTROL VOLTAGE ................ 24 VAC

FLAME SAFETY....Direct Spark Ignition of Main Flame, Electronic Safety

TABLE 1: Burner Specifications

1.

Standard burners are shipped as NATURAL gas models. Contact your Midco

®

dealer for

PROPANE gas burners.

2.

SCFM = Standard Cubic Feet / Minute.

3.

All Ratings Based on 1000 BTU/Cu. Ft. NATURAL and 2500 BTU/cu.ft PROPANE. Derate

burner for altitude over 2,000 feet by 4% for each 1,000 feet above sea level.

4.

1 MBH = 1,000 BTU/hr.

5.

For 50 Hertz applications the RE4400DS and RE4400DSA will be derated by 20%. Contact the

factory for details. NOTE: Burners rated for 50Hertz are not UL Listed.

____________________________

CAUTION: The ECONOMITE Model RE4400DS and RE4400DSA Burners are

not intended for outdoor installation and must be protected from excessive moisture.

Provide adequate clearance for service and proper operation.

If the former automatic oil burner gave trouble-free operation, it is probable that the heating

plant area has sufficient infiltration of air for combustion and dilution of flue gases.

Nevertheless, the area must be checked.

? Open basement or utility areas of normal construction, without storm windows or tight

doors, will generally allow sufficient air infiltration. However, if the heating plant is located in

a tight or separate room, ventilation to an open area as described above will be required.

Install two permanently open grills, each sized on the basis of one square inch free area per

1,000 BTU (but not less than 100 square inches) of the total input rating of all gas utilization

equipment in the combined space. One grille should be located within 12 inches of the

ceiling, the other within 12 inches of the floor.

?? If the heating plant is located in an area of unusually tight construction, or if an exhaust

fan, kitchen ventilation system, clothes dryer and/or fireplace is installed in the building,

provisions must be made for an outside air supply near the heating appliance area. Install

permanently open grills sized at not less than one square inch free area per 4,000 BTU of

burner input. When ventilating through horizontal ducts, grills should be sized at not less

than one square inch free area per 2,000 BTU of burner input. In any case, the minimum

dimension of rectangular air ducts shall not be less than 3 inches.

? In Canada, for detailed ventilation requirements, refer to standard CAN 1-B149.1 or .2

and/or local codes.

____________________________

? Clean the gas utilization equipment combustion chamber, heat exchanger interior, and flue

connections. Remove all adhering tars, scale, dirt and soot. Inspect for actual or potential

leaks.

? Cement all joints, including those in the heating appliance base and around the door

frames, to prevent leakage into, or out of the combustion chamber.

? The access or firing door should open easily to relieve pressure. If positive latches exist,

they should be modified to permit easy opening; a spring loaded door holder is

recommended.

? On all boilers, make certain the pressure relief safety valve is in good operating condition.

Part 1

Installation

2

I

Ventilation

II

Preparation of

the Gas Utilization

Equipment