Part 1 installation – Midco EC200 & EC300 User Manual

Page 7

Midco International Inc.

7

8471 38

Part 1 Installation

VIII - Burner Set-Up/

Adjustment

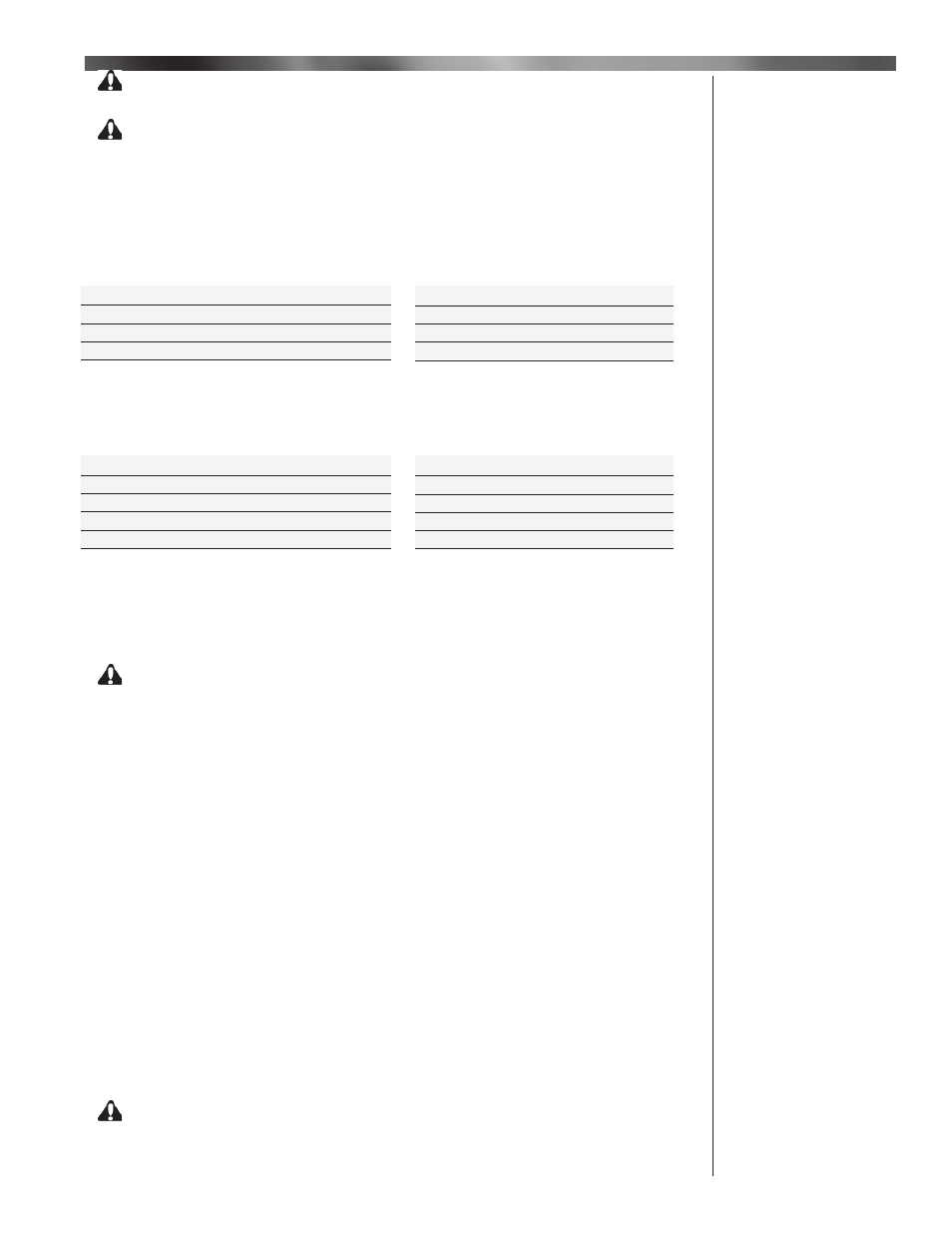

WARNING: Reposition the combustion air shutter for the maximum fi ring rate of the

selected orifi ce capacity range

CAUTION: The approximate air and gas settings described below are for initial

start-up only. Final start-up settings must be made in accordance with Section VIII, Burner

Set-Up/Adjustment Instructions for the manifold gas pressure are detailed in Section XIII,

Combination Gas Valve.

EC 200

Natural

Gas

Propane

Gas

Heat

Manifold

Air

Orifi ce

Air

Manifold Air

Orifi ce

Air

Input

Gas

Shutter Size

Restrictor

Gas

Shutter Size

Restrictor

BTU/Hr Pressure

Position

Pressure Position

″

W.C.

″ W.C.

70000 2.6

1.0

0.173″ On

1.2

1.0

0.173″ On

100000 1.0

2.0

None

On

2.3

2.0

0.173″ On

150,000 2.6

7.0

None

On

1.2

7.5

None

On

200,000* 4.1

9.0

None

None

1.8

9.0

None

None

EC 300

Natural

Gas

Propane

Gas

Heat

Manifold

Air

Orifi ce

Air

Manifold Air

Orifi ce

Air

Input

Gas

Shutter Size

Restrictor

Gas

Shutter Size

Restrictor

BTU/Hr Pressure

Position

Pressure Position

″

W.C.

″ W.C.

90,000 2.5

1.0

0.173″ On

1.1

1.0

0.173″ On

150,000 1.3

3.0

None

On

2.8

3.0

0.173″ On

200,000 2.2

6.5

None

On

1.2

6.0

None

On

250,000 2.9

6.0

None

None

1.6

6.0

None

None

300,000* 4.0

9.0

None

None

2.1

9.0

None

None

* As Shipped from Factory

___________________________

WARNING: Ignition is automatic. Make spark observations into combustion chamber

only with Main Manual Shut-Off Valve closed. Confi rm that gas utilization equipment does not

contain any accumulated gases. Purge as described in Step 10 below.

1. Before burner start up, be sure to study and familiarize yourself with the exact sequence of

operation and all other details of this burner and the gas utilization equipment.

2. Check the burner piping and valves for gas leaks by applying a weak liquid soap solution to

unions and joints with the gas supply on. Leakage will be indicated by the appearance of soap

bubbles. Locate and correct all gas leaks before proceeding.

3. Purge the air from the gas supply line to expedite the fi rst light off.

4. Ensure the gas utilization equipment is in the proper operating condition.

5. Attach two gas manometers to the burner. Connect one to the inlet pressure tap of the gas

valve and the other to the outlet pressure tap of the gas valve.

6. Connect a microampmeter to the ignition controller to monitor the fl ame signal during the start

up process. Refer to the ignition control specifi cation sheet that is supplied with the burner for

proper lame signal requirements and sequence of control operation.

NOTE: Midco International reserves the right to change ignition controller or other components

without notice.

7. Set the burner air shutter to the proper setting according to the recommended data in Table 3

for zero draft condition.

8. To

RE-SET the Electronic Burner Control a manual re-set is required. Turn the operating control

to Off or set the thermostat below room temperature for at least 30 seconds, or remove the 24v

for a period of 5 seconds, see Section XIV, Electronic Burner Control.

9. Confi rm that Main Manual Shut-Off Valve is open. Turn Manual Gas Cock Knob on Combination

Gas Valve to ON.

CAUTION: Purge gas to outside the building. Do not purge into the gas utilization

equipment.

VII Main Gas Spud

Continued

Table 3: Recommended Air Shutter Setting at Zero Draft Conditions and Orifice Size