Installation – Martin Sprocket & Gear Bucket Elevator Safety User Manual

Page 9

Installation

5

JB. Move boot take-up to its uppermost position (head end take-up to lowest position.) Make these adjustments uniformly to

both sides at the same time. Many bearings will not accommodate much misalignment. Severe damage to internal bearing

parts and seals can occur if this procedure is not followed.

KB. It is recommended, especially in cool environments, that the belt be draped over the head pulley and allowed to hang for at

least 24 hours. This will relieve stresses resulting from being rolled up and tend to achieve initial stretch common to belting.

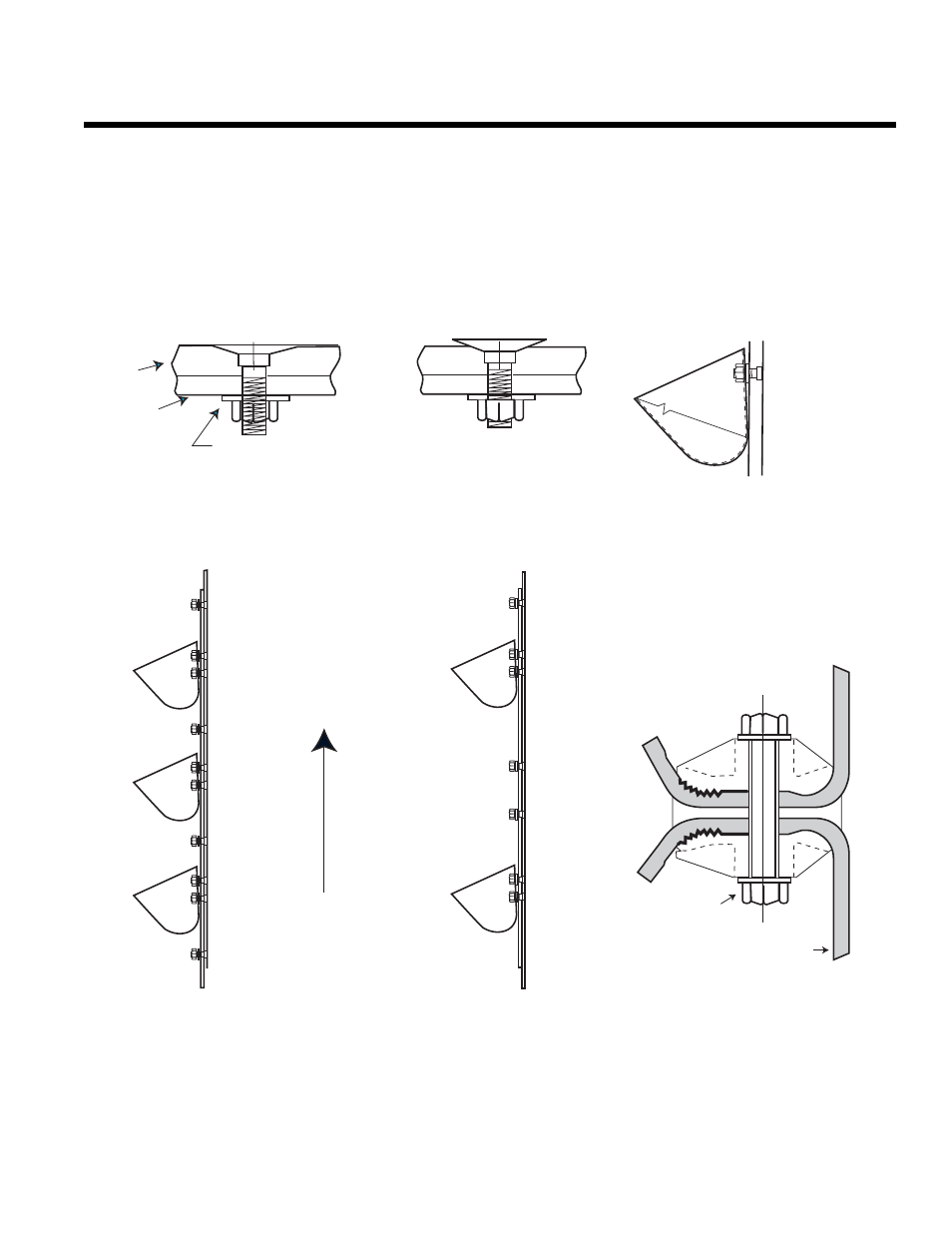

ATTACHING BUCKETS TO ELEVATOR BELTS

If rubber covered belt with unequal thickness covers is used, the thicker cover should be installed on the pulley side.

LAP JOINT

BUTT JOINT

CLAMP SPLICE

LB. Select the type of splice to be used from illustrations above.

MB. Clamp belt several feet from both ends using clamping angle irons and pull ends until a snug tension is achieved. Splice belt

by installing elevator bolts, nuts, and washers. Often it is desirable to add one or more rows of additional bolt holes between

buckets in the splice area. This is accomplished by drilling the holes while the belting is clamped in the pretensioned condi-

tion. If clamp splice is used follow instructions supplied with clamps.

PROPER

IMPROPER

SPACER WASHER

(OPTIONAL)

FLAT WASHER

WITH PLASTIC BUCKETS

BELT

BUCKET

F

L

O

W

End Piece #1

End Piece #2

Center Piece

PVC

or

Rubber Belt

1/2" Diameter

4" Long

Grade 5 Bolt

Anti Self-Locking

Nut

Center Piece