Bolt torque, General bolt tightening torque – Martin Sprocket & Gear Bucket Elevator Safety User Manual

Page 17

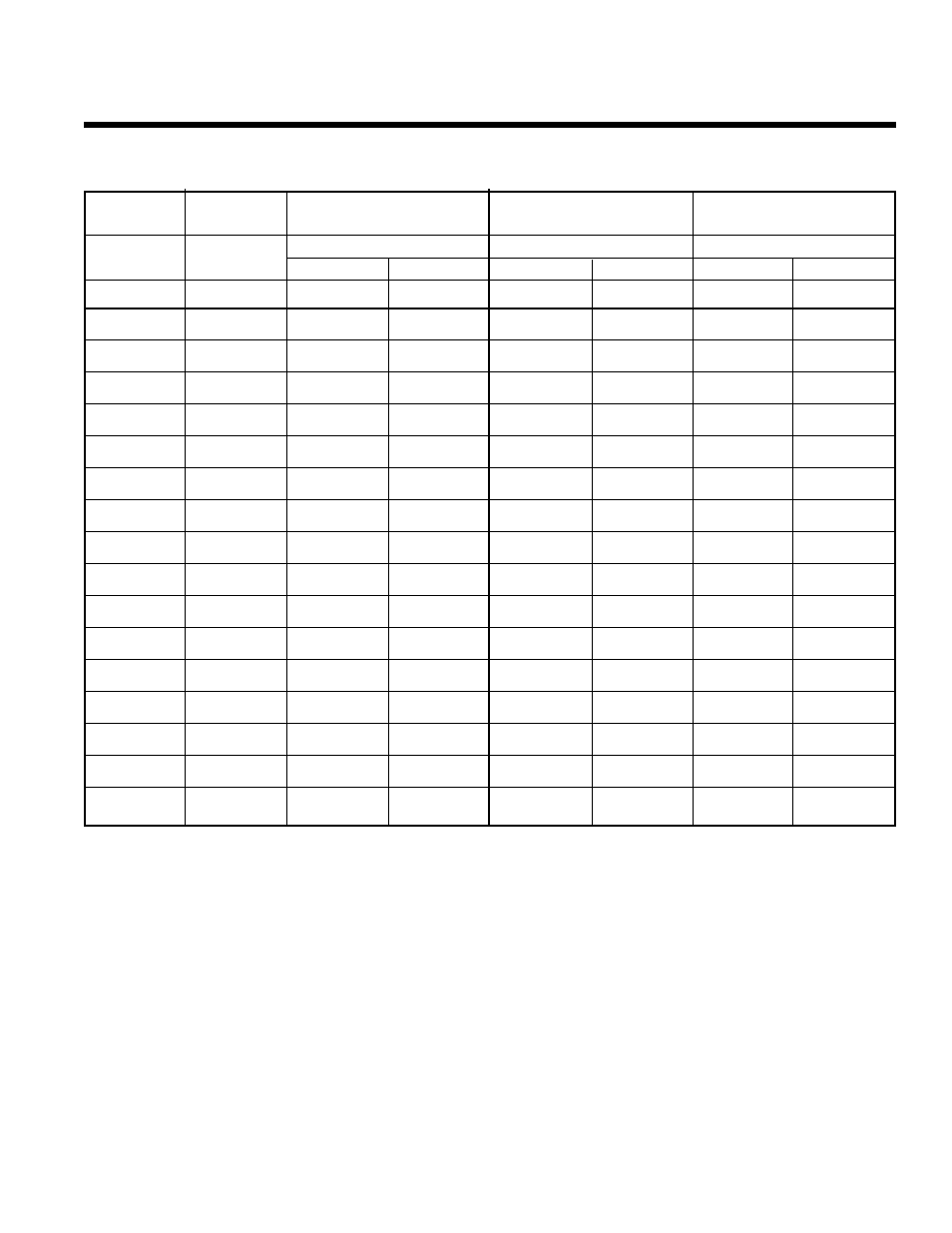

Bolt Torque

13

General Bolt Tightening Torque

Thread

Tensile Stress

Area

SAE Grade 2

SAE Grade 5

SAE Grade 8

Size

Tsa

75% Yield Strength (PSI) - 43000

75% Yield Strength (PSI) - 69000

75% Yield Strength (PSI) = 98000

Plain

Zinc Plated

Plain

Zinc Plated

Plain

Zinc Plated

Square Inches

Ft.Lb.

Ft.Lb.

Ft.Lb.

Ft.Lb.

Ft.Lb.

Ft.Lb.

1/4-20.

0.0318

6

6

9

10

13

14

1/4-28.

0.0364

7

7

10

12

15

16

5/16-18.

0.0524

12

13

19

21

27

29

5/16-24.

0.0580

13

14

21

23

30

33

3/8-16.

0.0775

21

23

33

37

47

52

3/8-24.

0.0878

24

26

38

42

54

59

7/16-14.

0.1063

33

37

53

59

76

83

7/16-24.

0.1187

37

41

60

66

85

93

1/2-13.

0.1419

51

56

82

90

116

127

1/2-20.

0.1599

57

63

92

101

131

144

9/16-12.

0.1820

73

81

118

129

167

184

9/16-18.

0.2030

82

90

131

144

186

205

5/8-11.

0.2260

101

111

162

179

231

254

5/8-14.

0.2560

115

126

184

202

261

287

3/4-10.

0.3340

180

197

288

317

409

450

3/4-16.

0.3730

200

221

322

354

457

503

The reason all applications should be evaluated to determine the optimum tightening torque is that the K

factor in this formula is always an estimate.

The most commonly used bolting K factors arc 0.20 for plain finished bolts, 0.22 for zinc plated bolts,

and 0.10 for waxed or highly lubricated bolts

Formula: T= K x D x P

• T

Target tighten torque (the result of this formula is in inch pounds, dividing by 12 yields foot pounds

• K

Coefficient of friction (nut factor), always an estimation in this formula

• D

Bolts nominal diameter in inches

• P

Bolt's desired tensile load in pounds (generally 75% of yield strength) - [ P(lbs) = (75%) Yield

Strength * Tensile Stress Area ]