Bolt torque guide, Chart a - bolt torque guide – Martin Sprocket & Gear Screw Conveyor Safety User Manual

Page 19

CEMA STANDARD NO: 352-2012

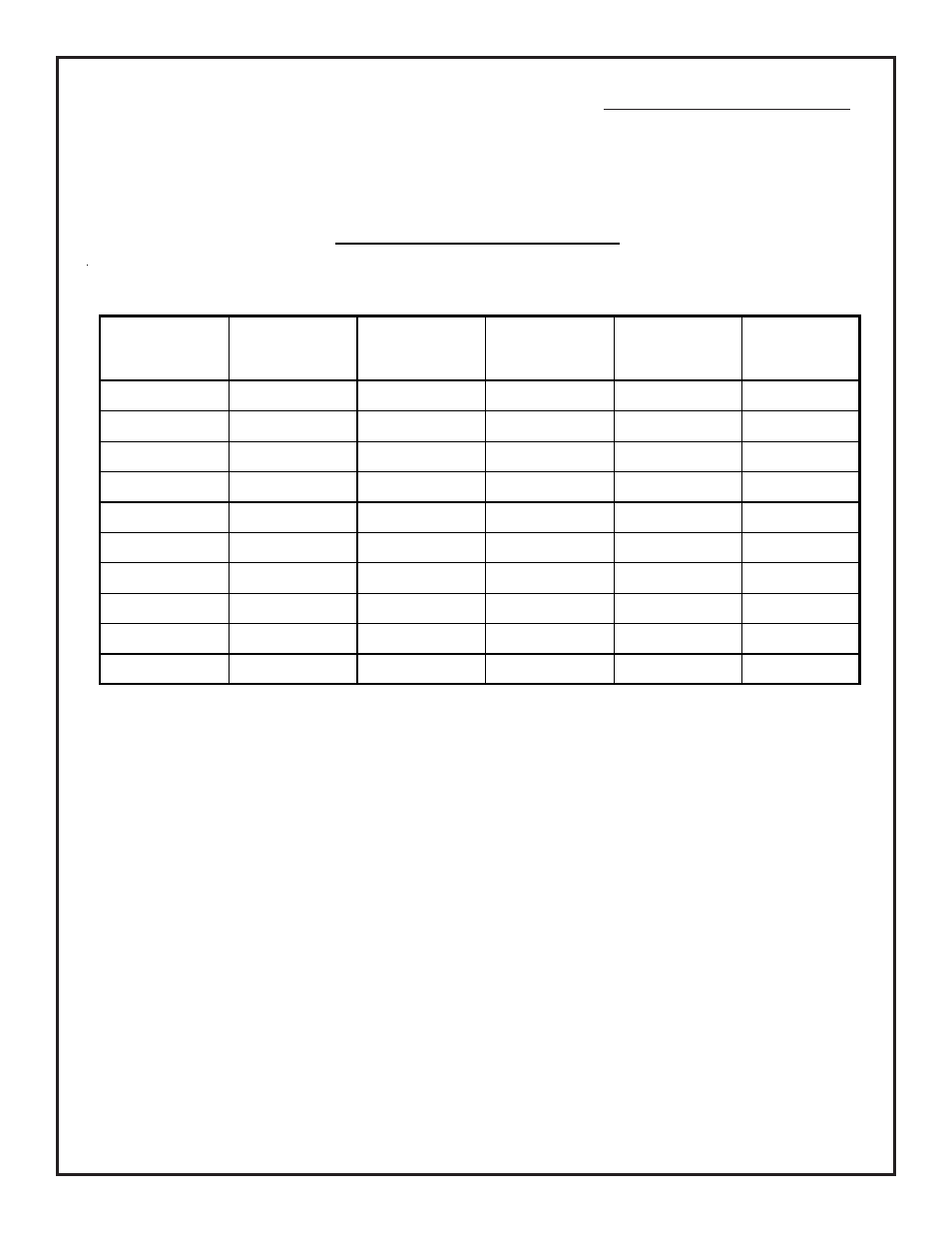

CHART A - BOLT TORQUE GUIDE

Formula: T= K x D x P

• T

Target tighten torque (the result of this formula is in inch pounds, dividing

by 12 yields foot pounds)

• K

Coefficient of friction (nut factor), always an estimation in this formula

• D

Bolts nominal diameter in inches

• P

Bolt's desired tensile load in pounds (generally 75% of yield strength)

[P(lbs) = (75%) Yield Strength * Tensile Stress Area]

Bolt Torque Guide is for fasteners used to assemble screw conveyors and does not include coupling bolts. Over

tightening of coupling bolts could result in failure in tension.

CEMA recommends tightening coupling bolts to 75-percent of the values given in the Bolt Torque Guide to

eliminate over tightening of coupling bolts

END OF DOCUMENT

15.

All bolted applications should be evaluated to determine optimum tightening torque.

K factor in the formula below is considered an estimate.

The most commonly used K factor is 0.20 for plain finished bolts.

Bolt Dia. (inches)

Threads Per Inch

(UNC)

SAE 2

SAE 5

SAE 8

18-8 & 316

Stainless Steel

1/4

20

5

9

12

6

5/16

18

11

18

25

11

3/8

16

18

31

44

20

7/16

14

28

49

69

29

1/2

13

44

73

105

40

9/16

12

63

108

149

52

5/8

11

96

147

212

86

3/4

10

158

252

351

115

7/8

9

219

389

552

180

1

8

316

589

784

240

GENERAL BOLT TIGHTENING TORQUE (Ft. lbs.)