Section f - troubleshooting guide – Martin Sprocket & Gear Screw Conveyor Safety User Manual

Page 17

CEMA STANDARD NO: 352-2012

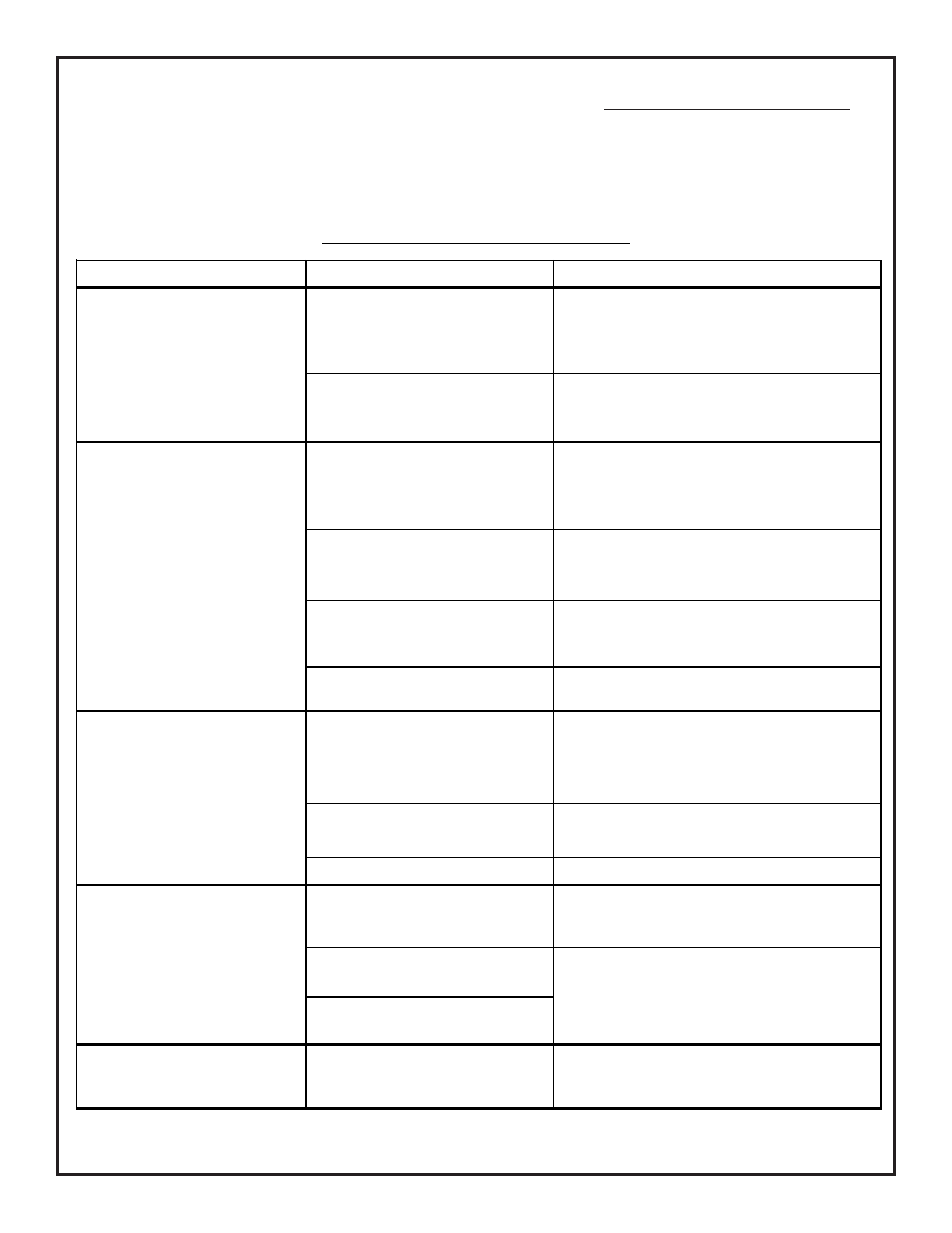

SECTION F – TROUBLESHOOTING GUIDE

13.

PROBLEM CAUSE

REMEDY

FLIGHT THICKNESS TOO LIGHT

INCREASE FLIGHT THICKNESS. USE ABRASION

RESISTANT METERIALS OR HARDFACING

RPM TOO HIGH OR TROUGH LOADING

TOO HIGH

REDUCE SPEED. CONSULT CEMA 350 BOOK TO

DETERMINE RECOMMENDED SPEED AND TROUGH

LOADING.

INCORRECT ALIGNMENT

REALIGN TROUGH ASSEMBLY AND HANGERS IN

ACCORDANCE WITH ASSEMBLY SECTION OF THIS

DOCUMENT.

IMPROPER SPEED AND TROUGH

LOADING

CONSULT CEMA 350 BOOK TO DETERMINE

RECOMMENDED SPEED AND TROUGH LOADING.

IMPROPER HANGER BEARING

MATERIAL

CONSULT CEMA 350 BOOK TO DETERMINE

RECOMMENDED BEARING MATERIAL.

EXCESSIVE BEARING WEAR

REPLACE HANGER BEARING.

TROUGH THICKNESS TOO LIGHT

INCREASE TROUGH THICKNESS.

USE ABRASION RESISTANT MATERIAL.

CONSULT CEMA 350 BOOK TO DETERMINE

RECOMMENDED TROUGH THICKNESS.

SCREW DEFLECTION

CONSULT CEMA 350 BOOK TO DETERMINE PROPER

PIPE SIZE AND SCRW LENGTH.

BENT SCREW

STRAIGHTEN OR REPLACE SCREW.

INSUFFICIENT NUMBER OF COUPLING

BOLTS

INCREASE NUMBER OF COUPLING BOLTS

CONVEYOR SUBJECT TO FREQUENT

STOP/START

FREQUENT OVERLOADS

5. DRIVE SHAFT BREAKAGE

EXCESSIVE TORQUE

CONSULT CEMA 350 BOOK TO DETERMINE PROPER

TORQUE RATING.

CEASE FREQUENT STOP/START. INCREASE BEARING

CAPACITY OF SHAFT AND/OR INCREASE NUMBER OF

COUPLING BOLTS

1. ACCELERATED FLIGHT WEAR

2. HANGER BEARING FAILURE

3. PREMATURE TROUGH FAILURE

4. SHAFT HOLE ELONGATION