Operation, Warning, Loading & feeding wire—mig – Hot Max Torches 250WFG User Manual

Page 12: Adjusting friction break, Mig gun parts—figure 16

Operation

KDAR Company

11

Loading & Feeding Wire—MIG

Note: Always turn power off when working inside

the welder enclosure.

Note: It is a good idea to take the contact tip off of

the gun prior to feeding the wire.

8” or 12” Diameter Spool

1. Remove the plastic tensioning cover (1), load

spool with wire coming from under the spool (for

8” spool put spool spacer on first). Replace plastic

tensioning cover (tighten enough so the spool does

not turn freely).

2. Flip down the wire tensioning arm (2) and flip up

the left and right idle arms (5). Make sure the

grove size on the drive roll (5) is in the feeding

position that matches the wire size being used.

3. Feed the wire through the input wire guide (3),

across the left side wire guide roller, through the

center wire guide, over the right side wire guide

roller and in to the output wire guide.

Note: In order to prevent the spool from un-

winding; it is important to keep tension on the wire

until after the idle arm and tension arm are back in

place.

4. Flip down the left and right idle arms and flip up

the wire tensioning arm.

5. Turn the welder on, press the Quick Feed Button

to advance the wire quickly through the gun hose.

Note: If feeding problem occur because the wire

is excessively flattened, turn the wing nut on the

spring loaded tension arm (1) counter clockwise to

reduce the pressure. If the drive roll (5) is slipping

while feeding the wire; turn the wing nut clock-

wise to create more tension on the wire.

1

Figure 15

2

3

4

5

Adjusting Friction Break

While turning the spool with one hand begin tight-

ening the plastic tensioning cover with the other.

Once you start to feel tension; then turn the cover

an additional 1/4 to 1/2 turn.

The intent is for the friction break to produce just

enough friction to prevent the spool from continu-

ing to turn after the drive motor has stopped.

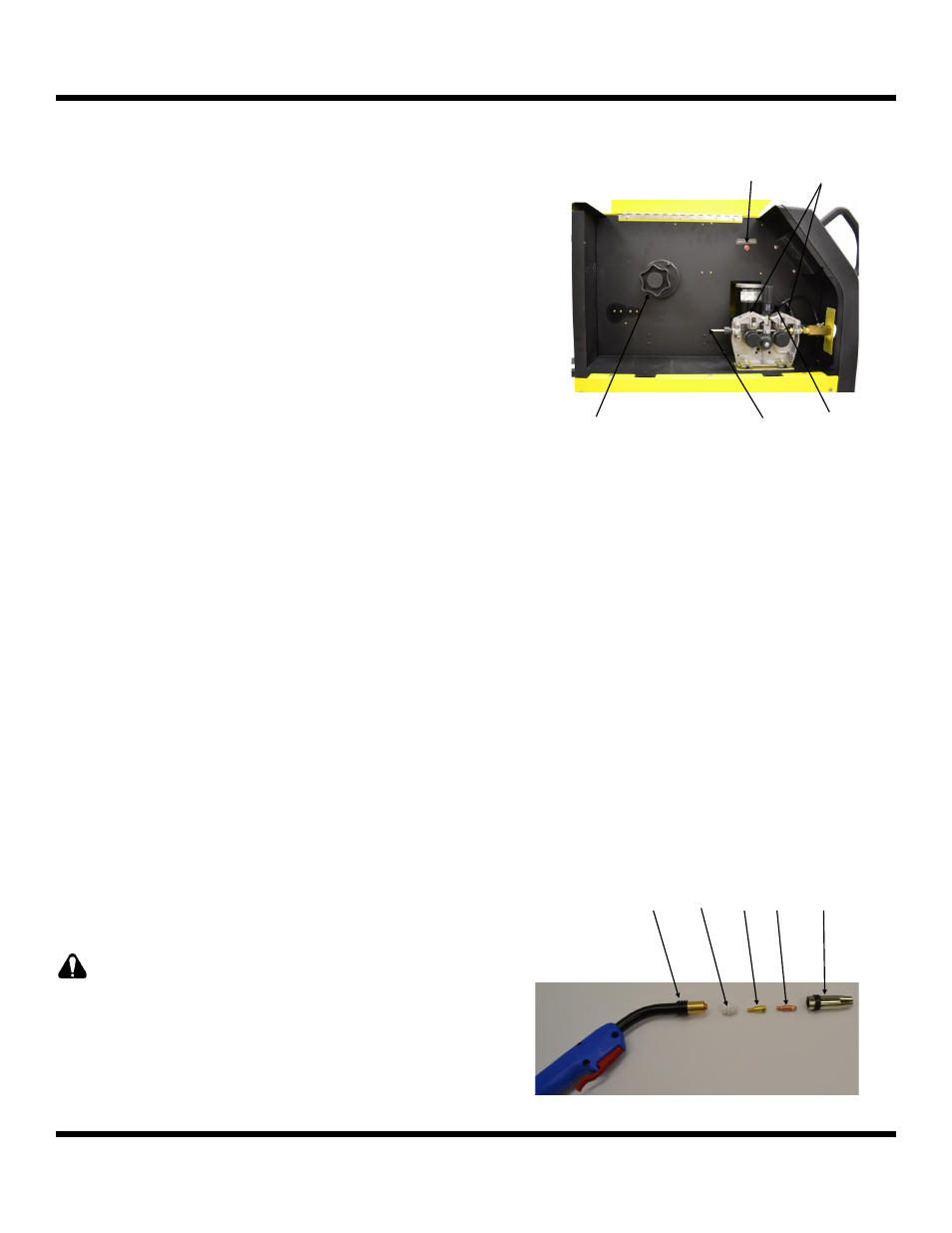

MIG Gun Parts—Figure 16

1. Gas Nozzle (1)

2. Contact Tip (2)

3. Contact Tip Holder (3)

4. Gas Diffuser (4)

5. MIG Gun (5)

Warning

When feeding the wire, the drive roll, the connector

block and gun contact tip are electrically charged

relative to work and ground and remain charged

for several seconds after the gun trigger is released.

1

2

3

4

5

Figure 16