Installation/setup, Warning – Hot Max Torches 175WFG User Manual

Page 9

Installation/Setup

KDAR Company

8

Cylinder can explode if damaged. Keep cylinder chained upright to a secure support.

Keep cylinder away from areas where it could be damaged.

Never lift or move the welder with the cylinder attached.

Do not let the welding electrode touch the cylinder.

Keep the cylinder away from welding or other live circuits.

Shielding Gas may be harmful to health or cause death.

Turn off gas supply when not in use.

Refer to American National Standard Z-49.1, “Safety in Welding and Cutting” from the

American Welding Society for more information.

Warning

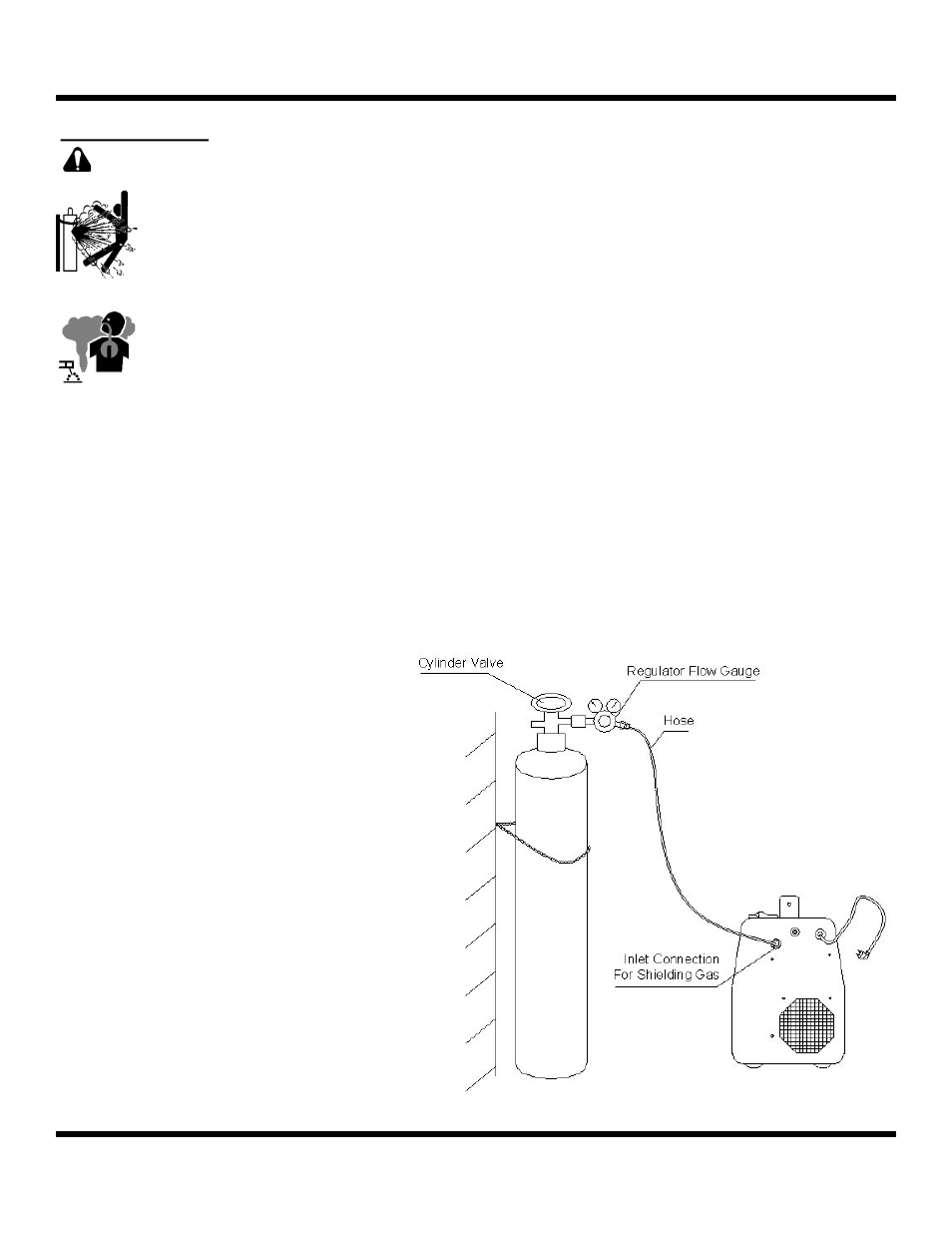

Gas Hook Up

When using the GMAW process, a cylinder of shielding gas must be used. Shielding gas cylinders and gas can

be obtained at a local gas supply company or some farm supply stores. The recommended gases for the Hot

Max 175WFG welder is either Welding grade CO2 or a Argon/CO2 blend with 75-80% Argon and 20-25%

CO2 (see Suggested Settings chart on the welder compartment door).

1. Insure the cylinder is properly secured to a wall or other stationary support to prevent it from falling over

during setup or operation. Be sure the cylinder is insulated from the work circuit and ground.

2. Once the cylinder is properly secured,

remove the cylinder cap. Standing to one

side slowly open the cylinder valve for an

instant to blow away any debris that may

have accumulated in the valve outlet.

3. Attach the flow regulator to the cylinder

valve and tighten with a wrench.

4. Attach one end of the gas hose to the out-

put fitting of the regulator and tighten

securely with a wrench.

5. Test to insure the flow regulator is closed

by opening cylinder valve slightly. If the

regulator is not closed turn the black

knob counter clockwise until the flow of

gas has stopped.

6. Connect the other end of the hose to the

gas inlet fitting on the 175WFG welder

making sure that the hose is not kinked or

twisted.

Gas Connection