Operation, Loading wire, Adjusting friction break – Hot Max Torches 175WFG User Manual

Page 13

Operation

KDAR Company

12

Loading Wire

Note: Always turn power off when working inside

the welder enclosure.

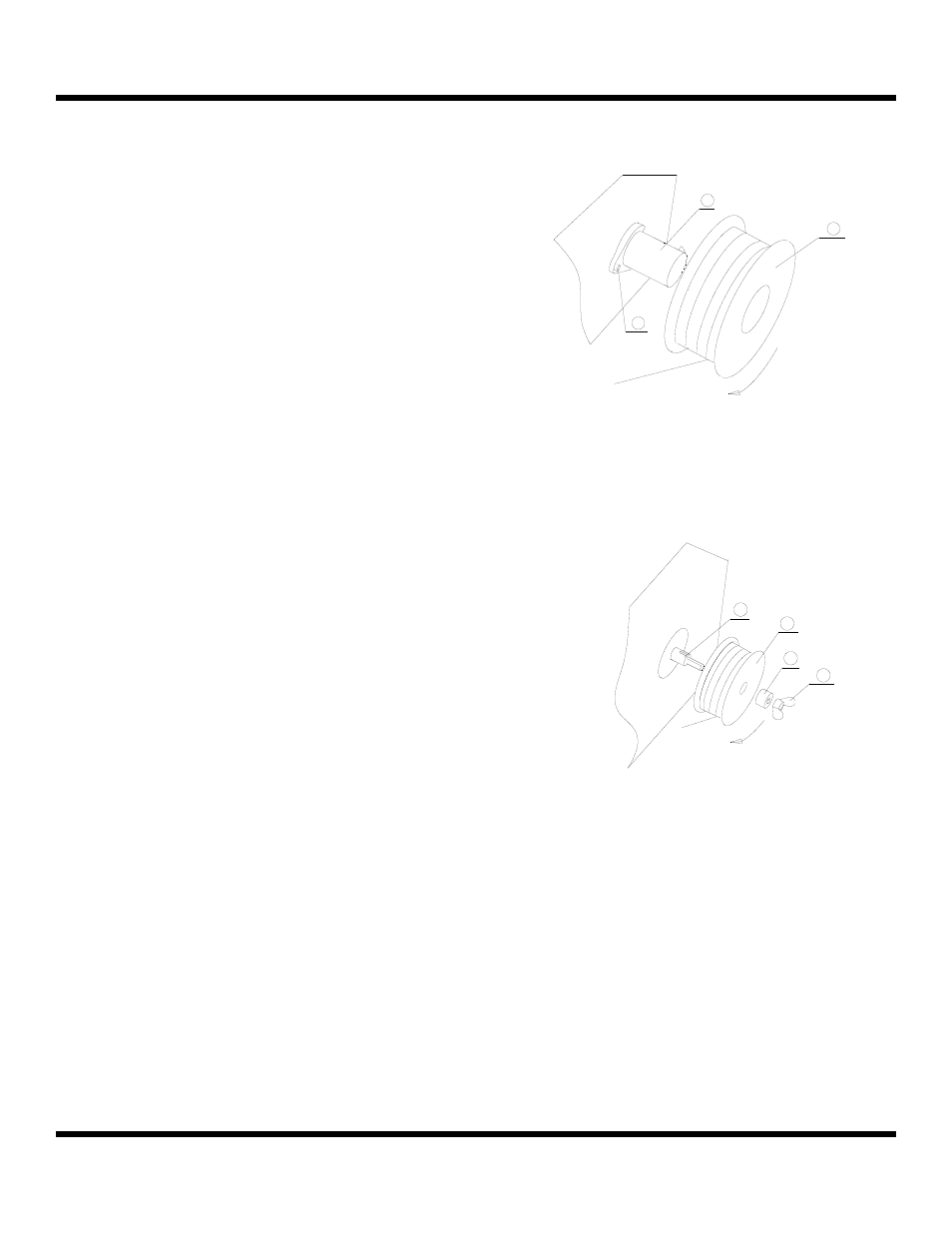

8” Diameter Spool

1. Remove the wing nut (5), and plastic tension spac-

er (6).

2. Place the spool adaptor (2) over the shaft as

shown.

3. Replace spacer and wing nut. Make sure the wing

nut is positioned so that it does not interfere with

the locking tab.

4. Place spool on the spool adaptor making sure the

hole in the spool engages the stud (3) on the spool

adaptor and the spool slides completely over the

locking tab.

4” Diameter Spool

1. Remove wing nut (5) and the plastic tension spacer

(6).

2. Place the spool (label out) on the shaft with the

wire feeding from under the spool.

3. Replace the spacer, washer and wing nut

Adjusting Friction Break

While turning the spool with one hand begin tighten-

ing the wing nut with the other. Once you start to feel

tension; then turn the wing nut an additional 1/4 to 1/2

turn.

The intent is for the friction break to produce just

enough friction to prevent the spool from continuing

to turn after the drive motor has stopped.

Use the welding wire board

with 4 "(100 mm) in diameter

Figure D-2

4

7

6

5

Use the welding wire board

with 8 "(200 mm) in diameter

Figure D-1

2

1

3