Maintenance schedule – Dake Euromatic Series User Manual

Page 35

370 S 370 S L 370 PP 370 PP L

35

Gear Box- 80 / 90 Gear Oil

Way Oiler-Light Weight Way Oil

Air Oiler - Tool Oil

Clean DRO Strip-Clean Dry Rag

EUROMATIC 370 PP / S MAINTENANCE SCHEDULE

NON-FERROUS HEAD

370PP/S

A Gear boxThe gear box does not require any oil. The horizontal spindle shaft has zerk fittings provided for

lubrication. The spindle should be greased with a high quality, high temperature grease.

B Air oiler Located on the air regulator

must be dry and clean. Use appropriate measures to insure, before it

enters the machine.

C Head feed cylinder. The oil reservoir is mounted into the cylinder. The reservoir is clear and you can visually

inspect the amount. When oil level is approximately depth of 1/4” oil must be added

To fill reservoir remove brass cap on top and add oil into the reservoir until full Cycle head to bleed.

D Chip drawer Located behind front access doorThis drawer pulls easily out for cleaning. If a chip collection unit has

been installed to the back of the machine, it should be emptied at regular intervals.

E Coolant pan is located under chip drawer. The coolant should be kept clean. When coolant needs changing, remove

the drain plug from the pan.

F Way Oiler. This reservoir is on the back of the column. This reservoir should be kept topped off. At the beginning of

each shift, this should be pumped twice to maintain good lubrication for the ways.

G Gib blocks. This acts as an adjustable guide for the gear box. If adjustment is needed see the gib block adjustment

section in this manual

H Vise gib can be adjusted by loosening the lock nuts and turning the set screws equally. This should be done when

ever vise shifts left or right when clamping.

I clean frequently any chips that build up within the vertical column.

J Belt tensioning should be done as needed.

BELT TENSION ADJUSTMENT

A: To adjust loosen the four motor mounting bolts. (Loosen slightly)

B: Using the adjusting bolt threaded into the block on the motor panel (H) adjust as needed.

C: Tighten motor mounting bolts securely.

Note: If you find no adjustment left in the threads, the belt may be stretched and in need of replacement. Belt tension

should have approx. 1/4 - 3/8” deflection.

On occasion if adjustment is not possible, loosen the motor mounting bolt and reposition the motor and try adjustment.

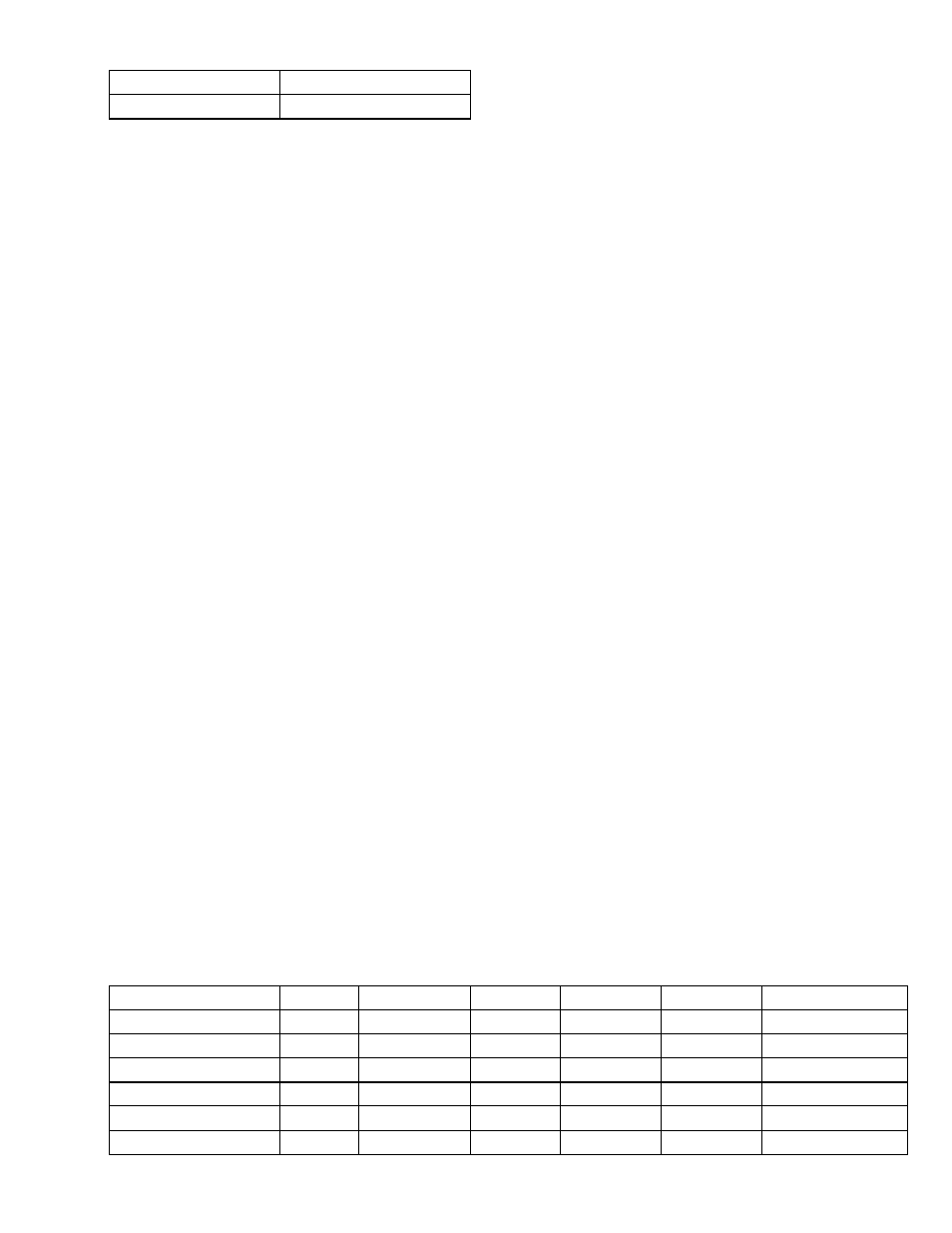

Maintenance Schedule

Item

Model

Daily

Weekly

Monthly

100 Hours

6 Months

Spindle grease

370 PP / S

as needed

Air Regulator oiler

370 PP / S

check / add

Head Feed Cylinder Oil

370 PP / S

add as needed

Coolant

370 PP / S

check / add

change

Chip Drawer

370 PP / S

empty

Gib Adjustment (Head)

370 PP / S

check

as needed