Warning – Dake Euromatic Series User Manual

Page 13

370 S 370 S L 370 PP 370 PP L

13

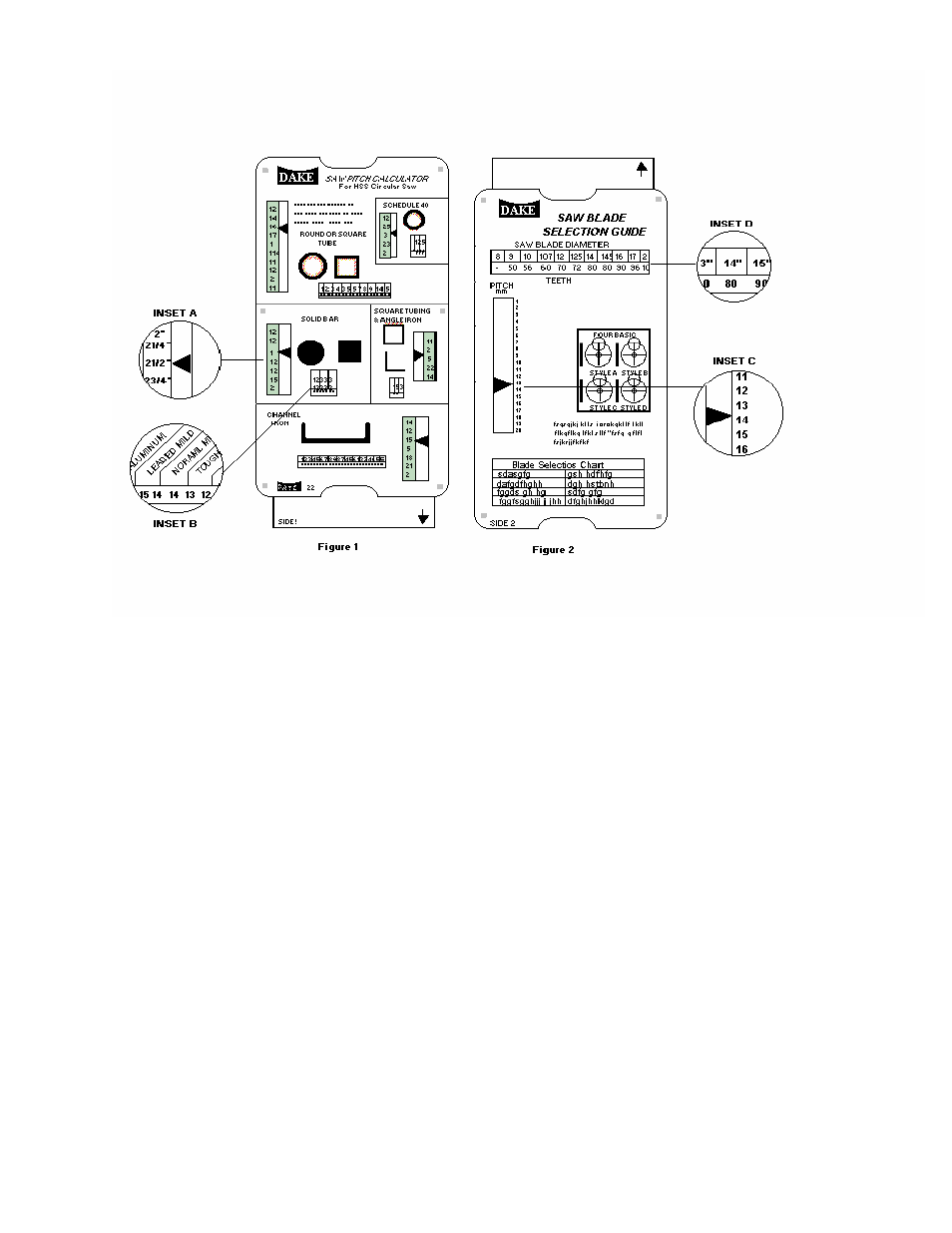

BLADE SELECTION FOR NON-FERROUS HEAD

Proper Blade Selection 370 Non-Ferrous

Same rules apply as with the ferrous head in selecting the "Right Blade for the Material". The larger the part the more

coarse teeth. The smaller or thinner the part, the more fine the teeth. An improper blade will sacrifice the cut safety and blade

life

Although the selection of teeth configurations, are more limited with carbide, here is a brief description of blade

recommendations for certain size materials.

1. For solid material from 2” to 4” (non-ferrous material) a 14” X 60th blade is used.

2. Solids from 1” to 2” a 14” X 84th blade is recommended.

3. For cutting material less than 1” a 14” X 100th is recommended.

4. Large extrusion with relief an 84th may be used.

5. Any thin wall tubing or small extrusions with relief should be cut with a 100th blade

WARNING!!!!!

Never use a blade that is cracked, dull or with chipped or missing teeth.