Caution, Warning – Dake Euromatic Series User Manual

Page 14

370 S 370 S L 370 PP 370 PP L

14

Different blade types

There are many different grinds for carbide. Positive pitch and negative pitch. You may select a positive pitch blade for more

aggressive cutting. A negative pitch for the more thin material. Also, different thicknesses for the blade are available. The same

rule applies here as for the Ferrous head, that high speed steel blade are available for the non-ferrous cutting head. These blades

may work better for some applications. And are normally run at the 1500 rpm setting.

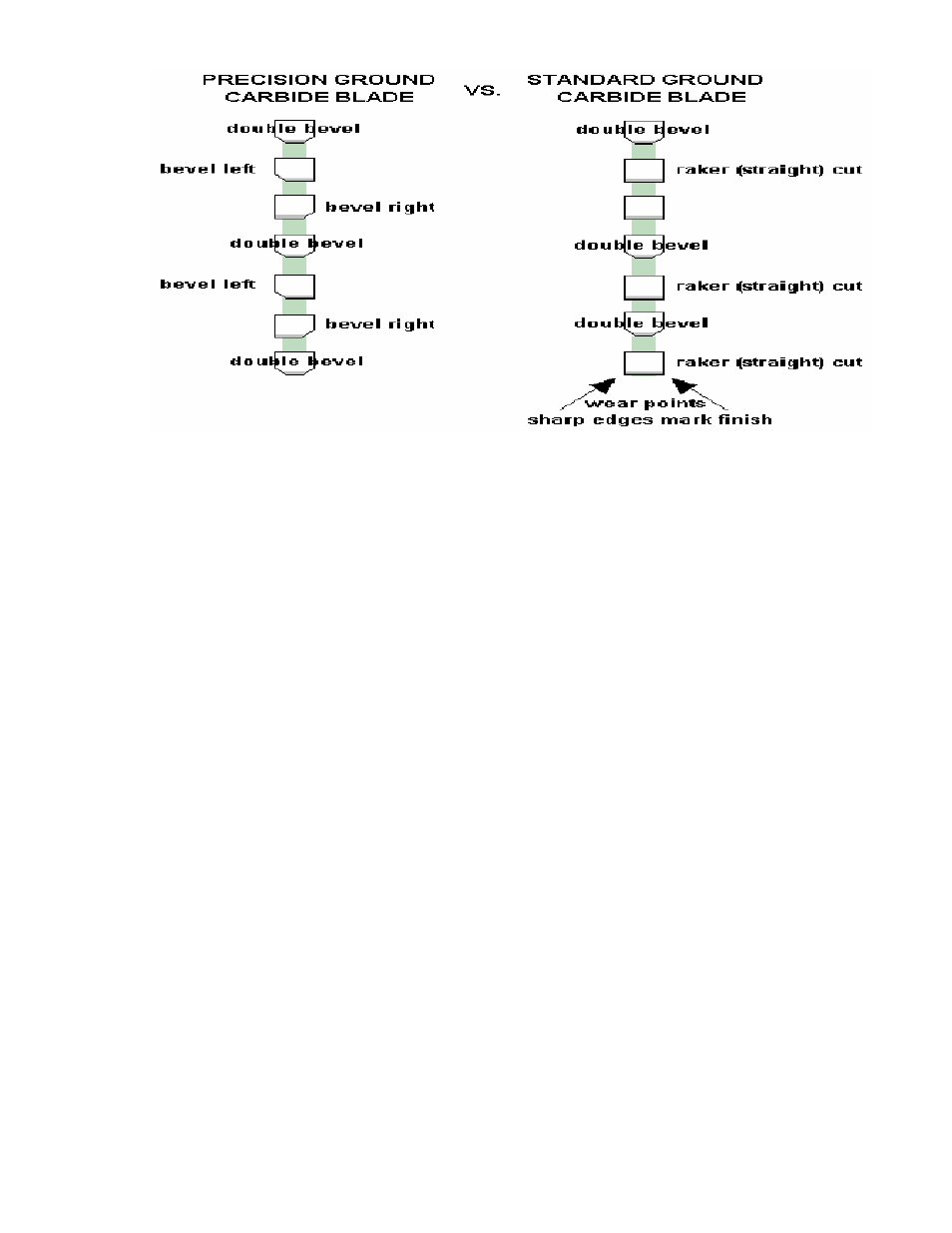

C: Precision ground carbide blades can be purchased for the non-ferrous head that will give you superior finish. A

standard ground carbide blade is cut with a double beveled tooth and a straight rake tooth and so on around the circumference

of the blade. A precision ground blade is beveled left, beveled right, and a double beveled tooth, around the blade without the

straight ground “rake” tooth, you eliminate much of the kerf marks a special grind may work for you. Call factory for

information on these blades.

The blade thickness can affect the way the blade will cut. A thinner blade may work better for you if you are cutting

thin wall tubing. The thinner blade has to remove less kerf, meaning the blade cuts less material.

CAUTION!!!!

Carbide blades should be reground only by a qualified professional.

Speeds and feeds

If the saw cuts without laboring through the cut the feed is correct the chip created on non-ferrous normally will not curl, Rule

of thumb if it sounds good and the chips look good you have it set right.

Note: 3000 rpm is the normal cutting speed for non-ferrous material with a carbide blade.

WARNING!!!!!

PROPERLY ADJUST ALL VISES BEFORE CUTTING. MAKE SURE THE BLADE WILL NOT STRIKE ANY

STEEL PARTS OF THE MACHINE. IF DEEP MITER CUTS ARE BEING MADE, LOWER WEAR PLATES MAY

NEED TO BE REPLACED WITH ALUMINUM PLATES, OR REMOVED AND A CLEARANCE CUT MADE INTO

THE PLATES WITH STEEL CUTTING SAW.