Warning – Dake Euromatic Series User Manual

Page 15

370 S 370 S L 370 PP 370 PP L

15

SETTING THE HEAD PARAMETERS

Warning!!!!!

Never depress the limit switches with your finger. Your finger could be crushed or amputated

between the limit switch and cam block.

Setting the head parameters

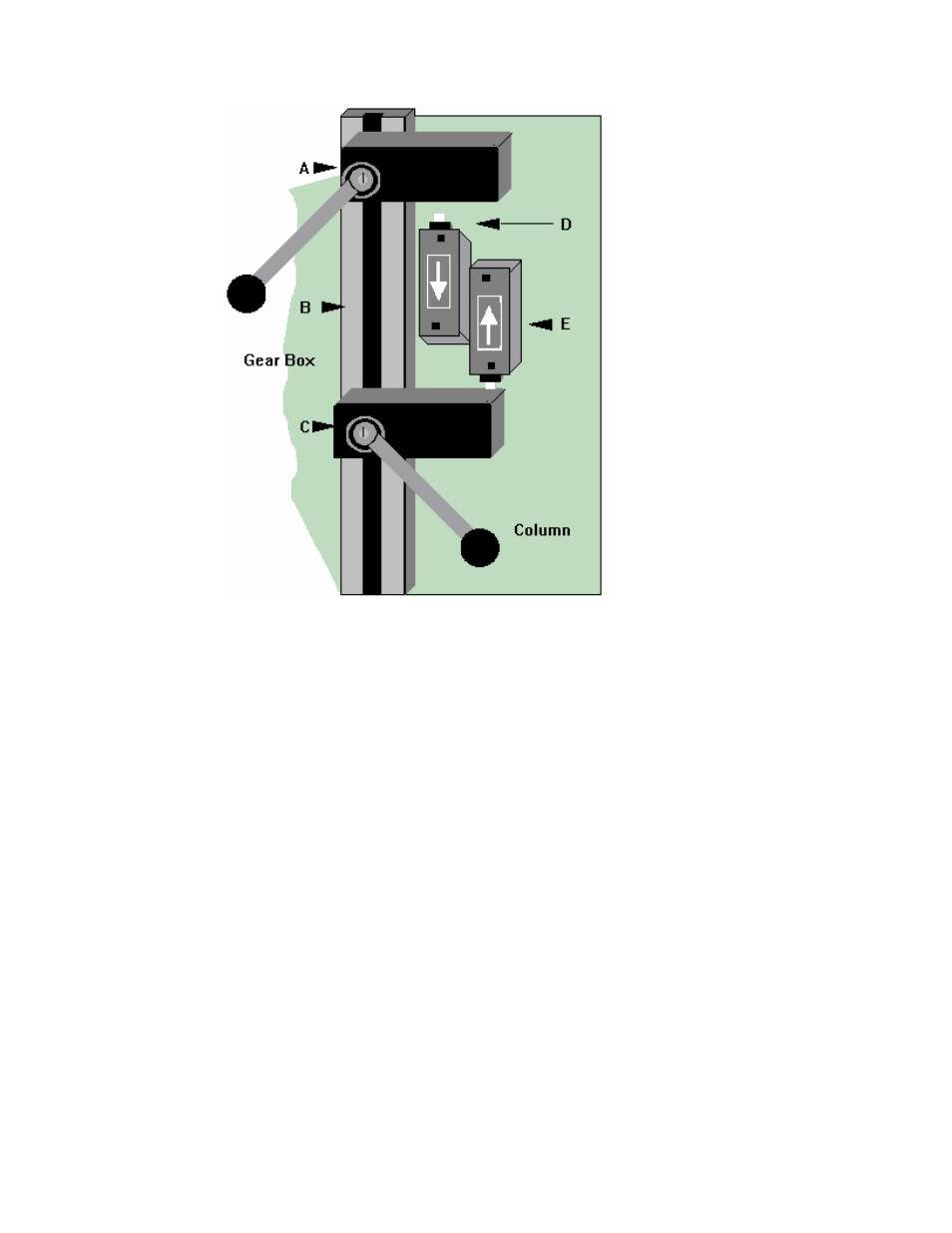

This is quite simple and very dependable method of reducing “dead air” cutting. The above graphic illustrates the four

basic parts of the head positioning system.

A is the lower limit, adjustable cam block.

B. is the machined T-slot way that the cams move vertically in.

C. is the upper head limit, adjustable cam block.

D. is the limit switch that will control the lower setting. When this switch is activated the blade stops and the head

returns to the upper setting.

E. This is the upper limit switch; this controls the head on the return stroke and stops it in the upper setting.

The gear box is on the left, and the vertical column is on the right side, as looking at the adjustments.

To set these parameters move the cams to the extreme positions and snug down. (The top cam up and the lower cam

down)

1. Power up the machine, and check that you have air pressure on the gauge.

2. Turn the speed selector switch to the “0” setting.

3. Place material in the main vise, and up to the blades path.

Do not place under the

Blade path. move the head feed control valve to zero.

4.

Make sure the emergency button is not engaged. On automatic machines (370 PP) place the cycle selector switch to the

“semi-auto” mode (hand symbol). Press the green cycle button (370S Yellow Button) (370PP push the green button then push

the yellow button) and slowly open the head feed valve. As the head descends downward toward the material, close the head