Caution – Dake Euromatic Series User Manual

Page 25

370 S 370 S L 370 PP 370 PP L

25

PROGRAMMING FOR MULTIPLE INDEXING

A: Three things that must be determined before programming for multiple indexing.

1

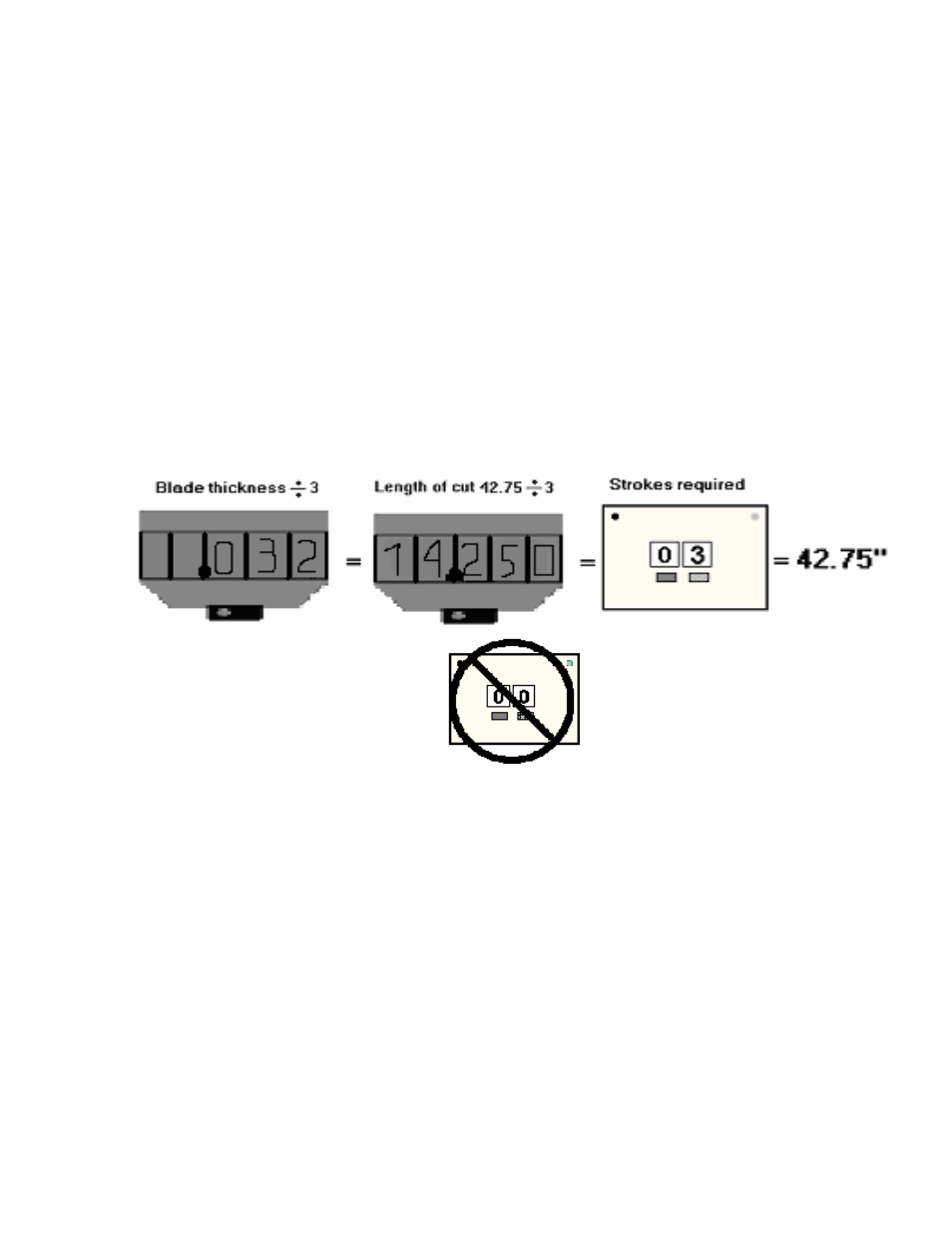

. Length of cut needed. How many equal strokes must be carried out to achieve this length Example: The length of

cut needed is 42.75”. We know a single maximum feed index is 20”. The length we need will require us to index the piece 3

times.

2. Now that we have established that 3 indexes are needed, we divide our length by 3. In the example our length is

42.75” divided by 3 gives us a length setting of 14.250”

Note: You may be tempted to feed the part at a shorter length, thinking it will feed faster at a short stroke. Example: The length

needed being 42.75” indexed 6 times at 7.125” With the variable feed speed adjustments, this will allow you to feed longer

lengths at

very quick speeds, meaning 3 long indexes will happen in less time than 6 short indexes.

3. Last we must figure what the true blade thickness is. This should be done by checking the blade kerf with a caliper.

The example we will use here is a blade thickness of 0.096”. Knowing we must index our part 3 times to accomplish

our length, we must divide our blade thickness by 3 times,

giving us a blade thickness of 0.032”

This is programmed into the equation as described in the DRO length set up chapter.

TIP: A shallow test cut into a scrap piece of material, then checking this cut with a caliper, will give you an

accurate measurement. This will show the thickness of the blade, plus any run out that may occur. All blades will have a

certain amount of run out, and this gives you the most accurate blade dimensioning.

This example is shown in the illustration below.

NOTE: A parameter of at least one must be entered into the multiple index counters, for the machine to cycle

in the automatic mode. If machine does not feed, make sure a digit is entered.

CUTTING IN THE AUTOMATIC MODE FOR THE 370PP

SETTING THE PIECE COUNTER

A: Power up the machine.

B: Place selector switch into the semi-auto position (hand symbol)

C. Place vise position switch (switch on the lower control panel, far right side item Q on page 9) to forward.

CAUTION!!!

This is very important. If this is not done, the feed vise will slam back and continue back until the

end of the cylinders stroke, when lock bolt is loosened. This may cause severe damage to the feeding

cylinder, and possible injury to the operat

D: Loosen the large lock handle on the feed cylinder, and set your length of cut.

Please read the section on setting

your length with the DRO section before proceeding.

E: With your length set, adjust your vises as described in the vise set up section.

F: Adjust your head positioning as described in the head limit section.