350 super technics, Machine functional parts – Dake Model Super Technics 350CE User Manual

Page 6

6

350 SUPER TECHNICS

350 SUPER TECHNICS

350 SUPER TECHNICS

350 SUPER TECHNICS

350 SUPER TECHNICS

4.5 - Instructions for electrical connection

- The machine is not provided with an electric plug, so the

customer must fit a suitable one for his own working conditions:

1 - WIRING DIAGRAM FOR 5-WIRE SYSTEM FOR THREE-

PHASE MACHINE - SOCKET FOR A 16A PLUG

1) Cast iron or ferrous materials, composed of metal alone, are

secondary raw materials, so they may be taken to an iron

foundry for re-smelting after having removed the contents

(classified in point 3);

2) electrical components, including the cable and electronic ma-

terial (magnetic cards, etc.), fall within the category of material

classified as being assimilable to urban waste according

to the laws of the European community, so they may be set

aside for collection by the public waste disposal service;

3) old mineral and synthetic and/or mixed oils, emulsified oils

and greases are special refuse, so they must be collected,

transported and subsequently disposed of by the old oil

disposal service.

NOTE: since standards and legislation concerning refuse in

general is in a state of continuous evolution and therefore

subject to changes and variations, the user must keep

informed of the regulations in force at the time of

disposing of the machine tool, as these may differ from

those described above, which are to be considered as

a general guide line.

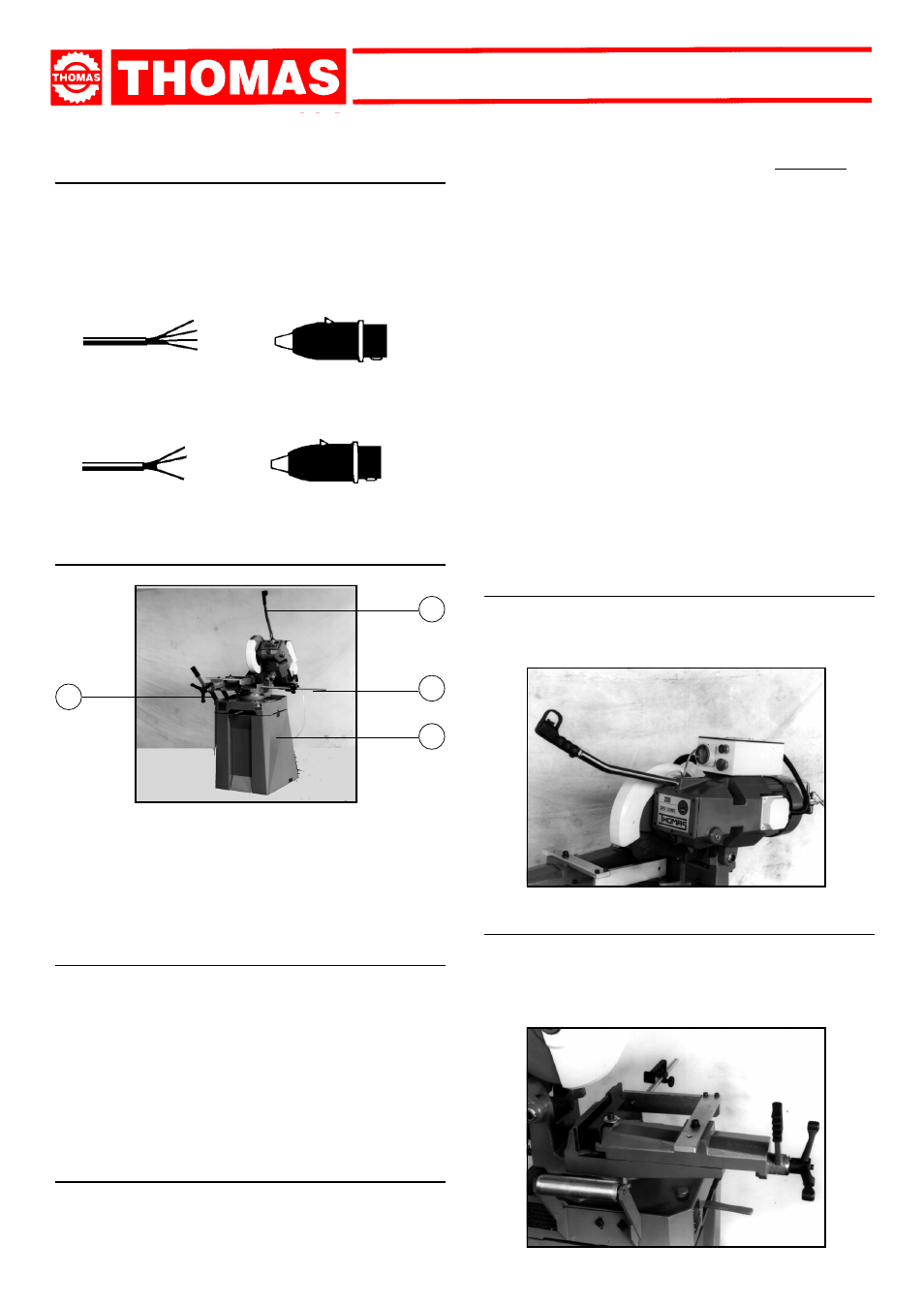

MACHINE FUNCTIONAL

PARTS

5.1 - Operating head

- Machine part composed of the parts that transmit movement

(motor, reduction unit), the lubricating coolant pump and the

electrical components.

5

2 - WIRING DIAGRAM FOR THE SINGLE-PHASE SYSTEM

SOCKET FOR A 16A PLUG

= L1

= L2

= PE

4.6 - Instructions for assembly of the loose parts

and accessories

2

1

3

4

5.2 - Vice

- System for gripping material during the cutting operation, by

means of the approach handwheel and rapid manual or

pneumatic locking lever (optional).

It is provided with an anti-burr device for blocking the part that

is to be cut.

Fit the components supplied as indicated in the photo:

- part. 1 Screw the lever onto the head and fix it

- part. 2 Fit the bar holding rod

- part. 3 Fix the pedestal firmly onto the base

- part. 4 Fit and align the roller carrying arm on the counter-

vice bench.

4.7 - Disactivating the machine

- If the sawing machine is to be out of use for a long period, it is

advisable to proceed as follows:

1) detach the plug from the electric supply panel

2) release the arch return spring

3) empty the coolant tank

4) carefully clean and grease the machine

5) if necessary, cover the machine.

4.8 - Dismantling

(because of deterioration and/or obsolescence)

General rules

If the machine is to be permanently demolished and/or scrapped,

divide the material to be disposed of according to type and

composition, as follows:

R = L1

S = L2

T = L3

PE = GND