Dake Model E-V Series User Manual

Page 23

7/21/08

Manual V-16, V-24, VH-24, V-40 & VH-40

23 – Section I

Turn the upsetting switch (3 figure 1) past the position (5 figure 1) to welding (6 fig. 1) and lock it for

about 3 seconds until the welding is completed. The current is switched off automatically.

Sparks spray out during welding, therefore stand at the side of the machine.

WARNING: BLADE WILL BE HOT!

5. ANNEALING

When the blade is heated in the butt welding process, the steel at the point of the weld “air hardens”

and becomes brittle. The anneal on/off knob is used to anneal the weld by reheating it. This returns the

blade close to its original condition.

After welding loosen the pressure clamps (7 fig. 1) and set the jaws to the wide annealing position by

turning the upsetting pressure switch (2 fig. 1) counter clockwise. Re-clamp the blade so that the weld

is in the center between the jaws. Operate the annealing switch (8 fig.1) until the weld becomes dark

cherry red. This will take from 1 to 5 seconds depending on the blade width. Allow blade to cool until

the blade returns to a dark color. Repeat this process at least three times. Some brittle alloys require

more annealing than the standard carbon blades.

Note: It is difficult to weld and anneal bi-metal blades due to the make up of this type of blade. It

will take some practice to successfully achieve a suitable weld.

WARNING: BLADE WILL BE HOT!

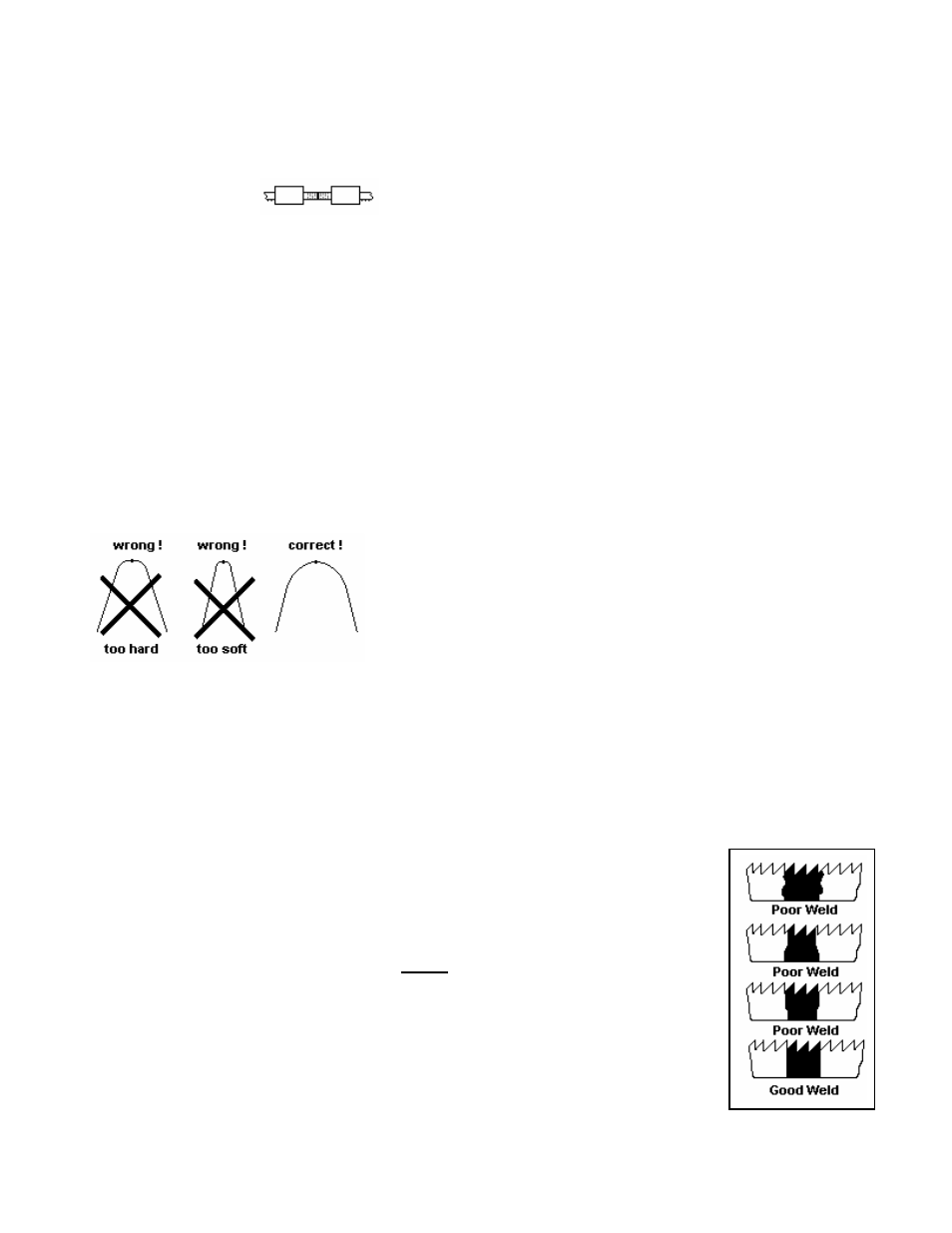

After annealing bend test your weld:

6. RE-FINISHING THE WELD

Welding burr (flash) can be removed by finishing with a grinding wheel above the welder. Grind in a

longitudinal direction, other wise transverse fractures may occur. The proper finish of the blade after

grinding, a tempered steel-blue coloring.

Note: Do not over grind, into the blade facing. Remove any burr on the back edge of the blade

.

WELDER LAYOUT AND CONTROLS

7. WELDER MAINTENANCE

If the clamping areas of the jaws are dirty or deformed so they so not clamp

evenly, good welds cannot be made. Any dirt or metallic debris must be

removed from the jaws. The jaws should never be filed. It should only be

polished with a proper cleaning material and if absolutely necessary polished

with fine emery cloth held on a flat piece of bar stock. The uniformity of current

flow and contact pressure can be checked by putting the welder in the

annealing position and clamping a piece of blade stock with out a weld in the

jaws. When the annealing switch is turned to the heating position the blade

should heat uniformly over its entire width. (See fig. 2) If the heating is not

uniform the clamping devices should be checked for dirt or misalignment.

figure 2