Dake Model E-V Series User Manual

Page 16

7/21/08

Manual V-16, V-24, VH-24, V-40 & VH-40

16 – Section I

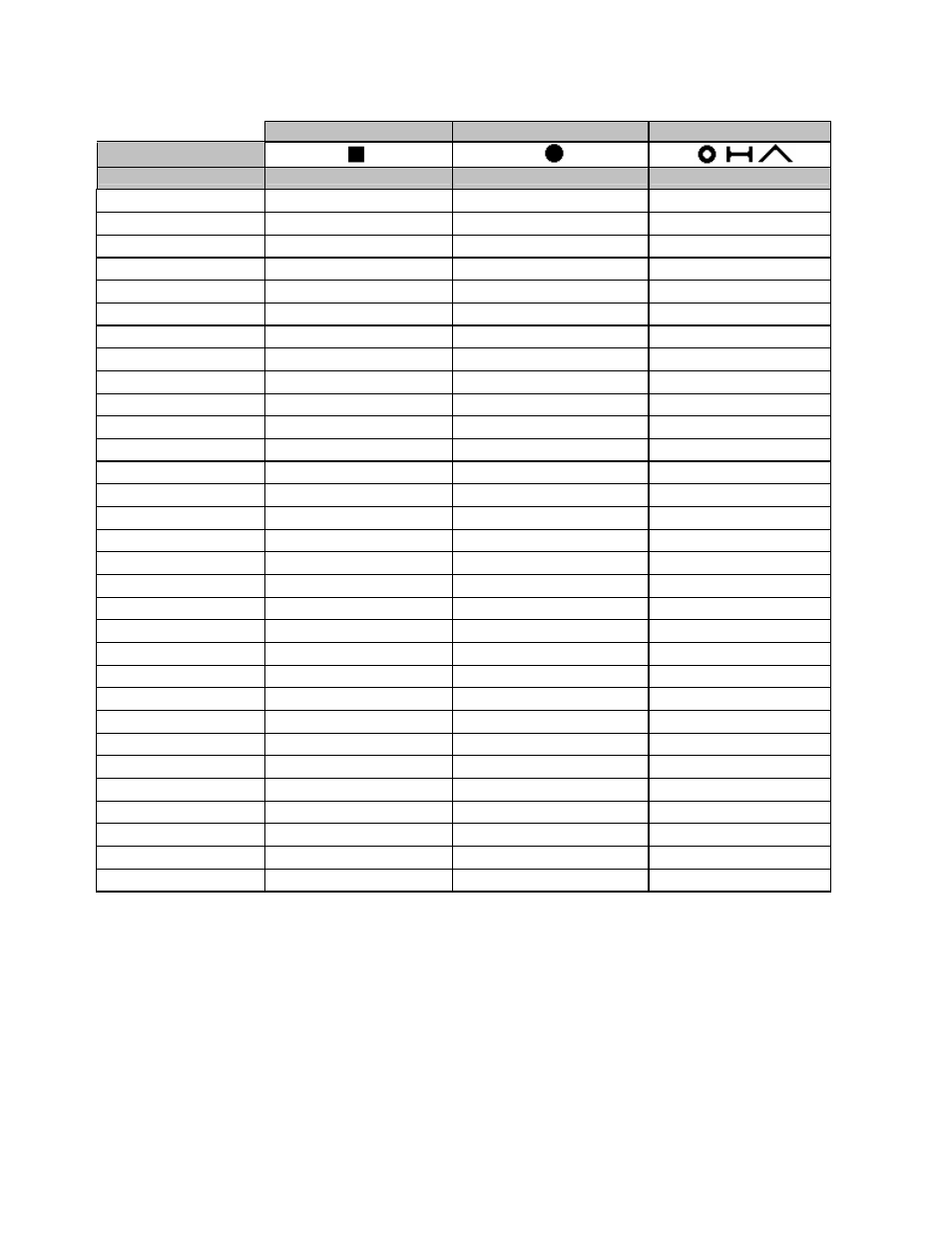

SAW BLADE SELECTION

MATERIAL SHAPE

MATERIAL SHAPE

MATERIAL SHAPE

MATERIAL IN

INCHES

TOOTH SELECTION

TOOTH SELECTION

TOOTH SELECTION

0

14 / 18

14 / 18

14 / 18

.1

14 / 18

14 / 18

14 / 18

.2

14 / 18

14 / 18

14 / 18

.3

10 / 14

14 / 18

10 / 14

.4

8 / 12

10 / 14

8 / 12

.5

8 / 12

8 / 12

6 / 10

.6

6 / 10

8 / 12

5 / 8

.7

6 / 10

6 / 10

5 / 8

.8

5 / 8

6 / 10

5 / 8

.9

5 / 8

5 / 8

5 / 8

1

5 / 8

5 / 8

4 / 6

1 1/4

4 / 6

5 / 8

4 / 6

1 1/2

4 / 6

4 / 6

4 / 6

1 3/4

4 / 6

4 / 6

4 / 6

2

4 / 6

4 / 6

3 / 4

2 1/4

4 / 6

4 / 6

3 / 4

2 1/2

3 / 4

4 / 6

3 / 4

2 3/4

3 / 4

4 / 6

3 / 4

3

3 / 4

3 / 4

3 / 4

3 1/4

3 / 4

3 / 4

3 / 4

3 1/2

3 / 4

3 / 4

3 / 4

3 3/4

3 / 4

3 / 4

2 / 3

4

3 / 4

3 / 4

2 / 3

5

2 / 3

3 / 4

2 / 3

6

2 / 3

3 / 4

2 / 3

7

2 / 3

2 / 3

1.4 / 2.5

8

1.4 / 2.5

2 / 3

1.4 / 2.5

9

1.4 / 2.5

2 / 3

1.4 / 2.5

10

1.4 / 2.5

1.4 / 2.5

1.4 / 2.5

11

1.4 / 2.5

1.4 / 2.5

1.4 / 2.5

12

1.4 / 2.5

1.4 / 2.5

1.4 / 2.5

SPEEDS AND FEEDS

As important as proper blade selection, is proper feeds and speeds for the different materials to be cut.

It is impossible to determine absolute rates for each material and machine, below is a chart that will

give you staring points for most applications; keeping in mind these are only approximations.

The left hand column, labeled Material tells you the family, the column Alloy lists the types that are

within that family of material. The top six columns give material dimensions. Below these column are

listed the recommended FPM and SIPM for that material type. Example: Carbon steel with a alloy make

up classified as 1030, with a diameter of 4” will be cut at 329 FPM and SIPM of 14, shown as fpm 329

sipm 14.