Dake Model E-V Series User Manual

Page 22

7/21/08

Manual V-16, V-24, VH-24, V-40 & VH-40

22 – Section I

This welder should not be used for welding 2% and 3% tungsten-alloyed metal cutting blades or HSS

blades.

The approximate valves for bi-metal blades are indicated in the matrix in the next column

.

Note: * The weld current step and upsetting pressure step have to be increased with some saw

manufactures. The saw blade has to be metallically clean and no tooth may enter into the welding

seam.

1. PREPARATION OF BLADE

Before welding the blade ends should be cleaned or rubbed with emery cloth on both sides of the blade

to a length of 1”, until they are metallically clean over the enter width.

Cut the blade ends accurately and at right angles. (See graphic below) Check

abutment against the stop for a cut at right angles. Proper welding can only

be achieved if the blade ends are cut with out a burr and at right angles. (Also

see trouble shooting section)

2. ADJUSTMENT

The initial jaw gap and upset force must be adjusted and

proportioned to the cross sectional area of the blade

being welded. A greater jaw gap will allow a wider or

thicker blade to reach proper welding temperature. A

greater upset pressure produces the same unit pressure

in welding a wider or thicker blade.

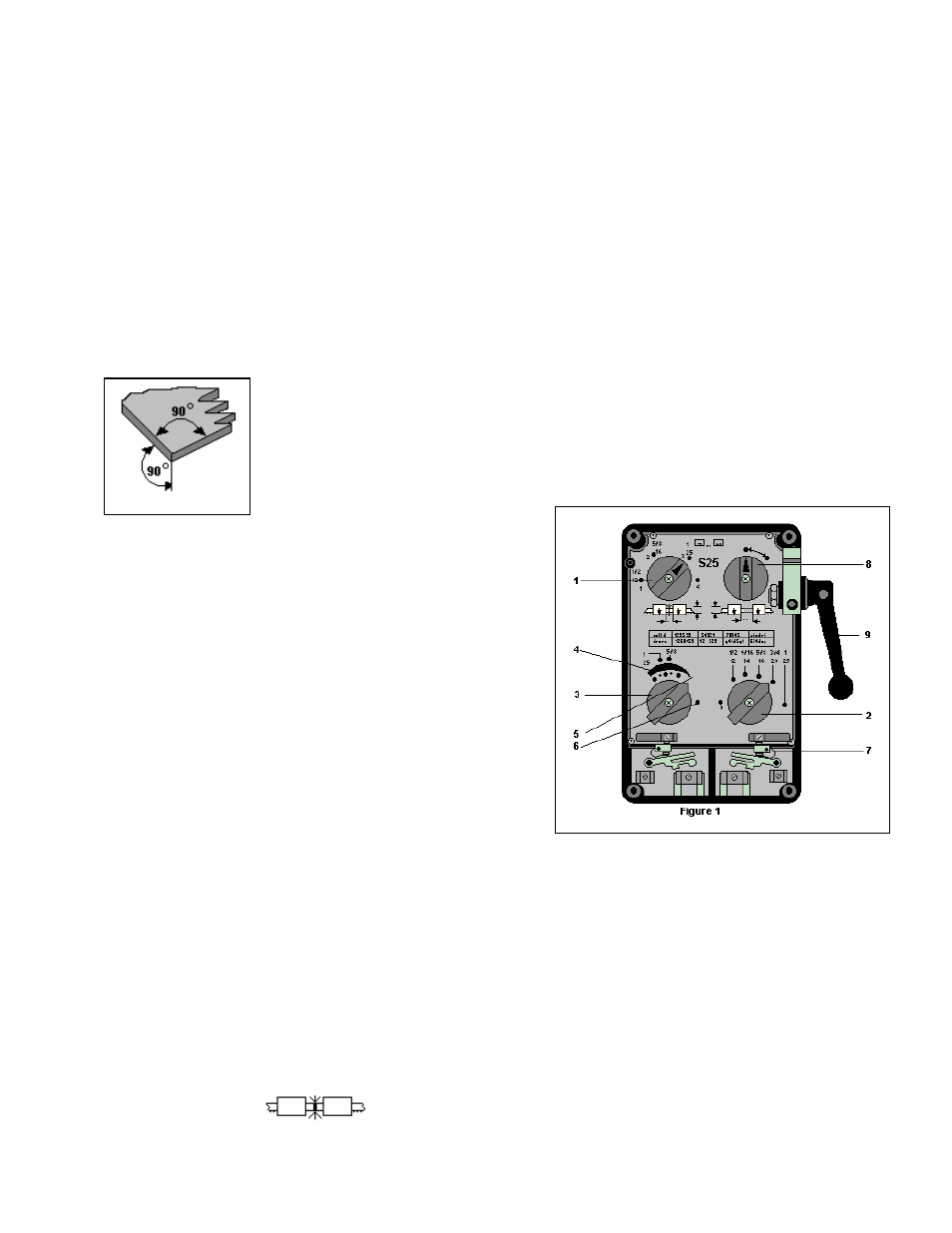

Set the welding current switch (1 figure 1), upsetting

pressure switch (2 figure 1) and the upsetting way switch

(3 figure 1) to the blade width to be welded. In view of

the wide range of material qualities and thickness scale

values are only guide values, which have been

calculated for commercial blades of 0.65 mm thick. Trial

welds should determine the correct settings for different steel qualities and thickness. Particularly thin

blades (0.4 mm) should be welded with a short upsetting way, high current and weak upsetting

pressure.

Example: Blade width is 1/2”. Current switch is set to 1/2” (number 1) position. The upsetting

pressure switch is set to 1/2” (number 1) position. The upsetting way switch is set to the 1/2” position.

3. CLAMPING THE BLADE ENDS

Insert the blade ends in the clamping jaws so that the joist is exactly in the center of the jaws. To

protect the jaws the blades should be inserted so the teeth are aligned at the front stops. Only blades

without teeth should be aligned at the rear stops. Leave slack in the blade coil, the blade must be free

so it can move easily during welding.

4. WELDING