Hydraulic feed table, Welding instructions general description – Dake Model E-V Series User Manual

Page 21

7/21/08

Manual V-16, V-24, VH-24, V-40 & VH-40

21 – Section I

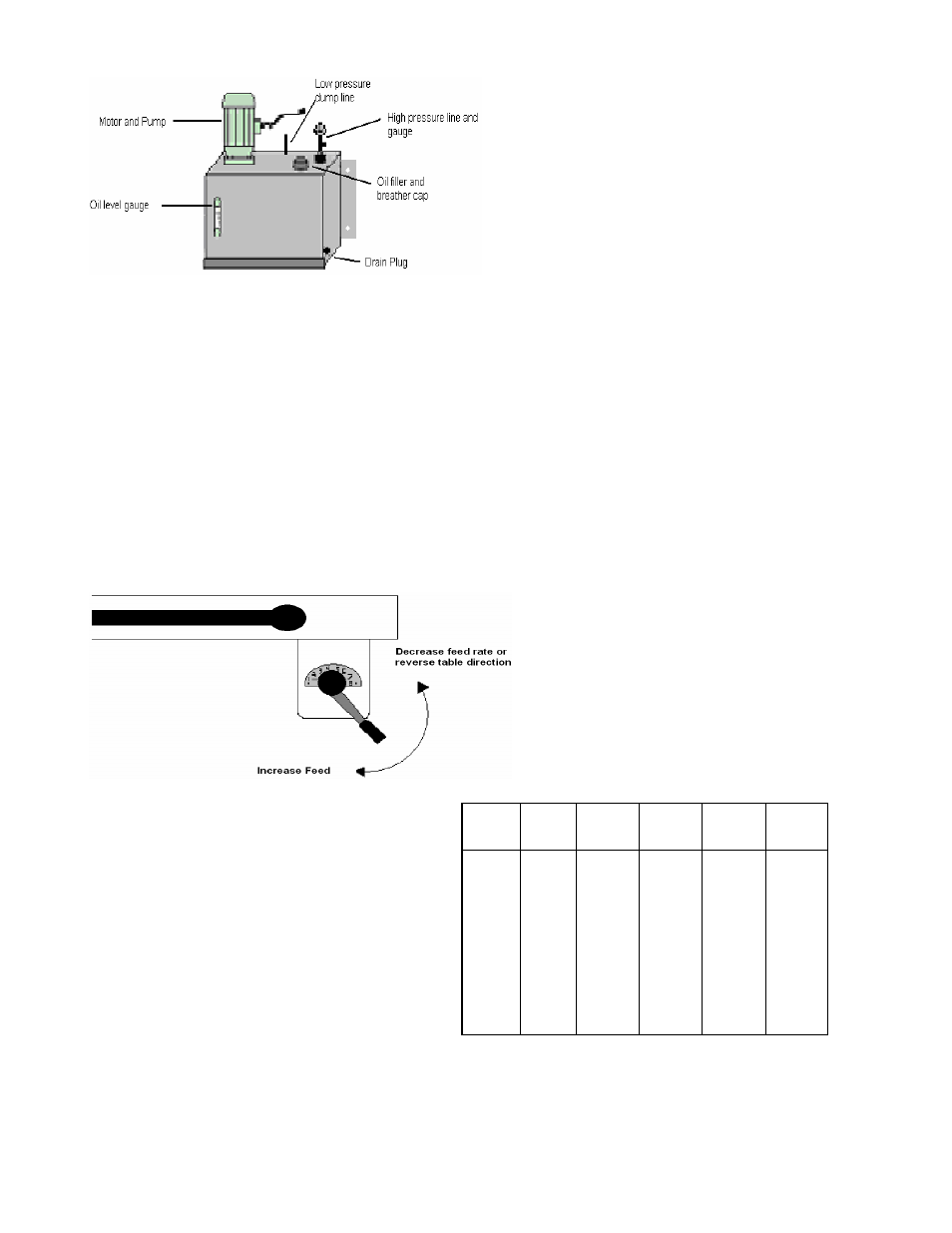

HYDRAULIC FEED TABLE

Machines equipped with a hydraulic feed table (VH models) have a pumping unit in the base. The

system has an adjustable relief valve, which is factory preset at 400 p.s.i. The systems oil level must be

checked periodically to assure the oil levels are maintained at the full level of the sight glass.

The feed table regulator will provide a smooth movement to the table. If the feed appears to be

intermittent it is probably due to air in the system. This is normally exhausted by running the table in

and out a few times.

To move the feed table, push the “hydraulic start” button on the control panel then, rotate the handle on

the front of the table to the right to start or increase the table feed rate. To move the table back to the

starting position rotate the handle to the left, there is only one speed for the reverse movement (see

diagram below).

WELDING INSTRUCTIONS

GENERAL DESCRIPTION

Note: Always wear eye protection when

using this welder or grinder!

Your Dake vertical band saw is equipped

with a “resistance-type” butt welder. The

two clamp jaws of the welder hold the

blade ends together. When the welding

start knob is turned fully clockwise past the

zero setting, electric current flows through

the blade ends creating enough heat to

soften and join them.

Note: This welder is suitable to weld

Metal blades 3 x 0.5 - 25 x 0.8mm

bi-metal blades 6 x 0.9 - 25 x 0.9mm

BANDSAW WELDING

CURRENT

UPSETTING

PRESSURE

UPSETTING

WAY

ANNEALING ANNEALING

mm

step *)

step *)

mm

COLOR

TIME SEC.

6 x 0.9

1 - 2

1

2.5

DARK RED

15

10 x 0.9

1 - 2

1

3.0

DARK RED

15

12 x 0.6

1 - 2

1

3.0

DARK RED

15

12 x 0.9

1 - 2

1

3.0

DARK RED

15

13 x 0.7

1 - 2

1 - 2

3.0

DARK RED

15

16 x 0.7

1 - 2

1 - 2

3.0

DARK RED

15

19 x 0.9

1 - 2

1 - 2

3.0

DARK RED

15

25 x 0.9

1 - 2

1 - 2

3.5

DARK RED

15