Hydraulic installation, Hydraulic set-up -14 - 2-15 – Summers 30' Superroller User Manual

Page 24

SECTION 2 - ASSEMBLY

-120

9/13/2010

9LR3042.iam/

A

B

8T1055

8K9106

8K9106

8D9108

8D9108

8K9102

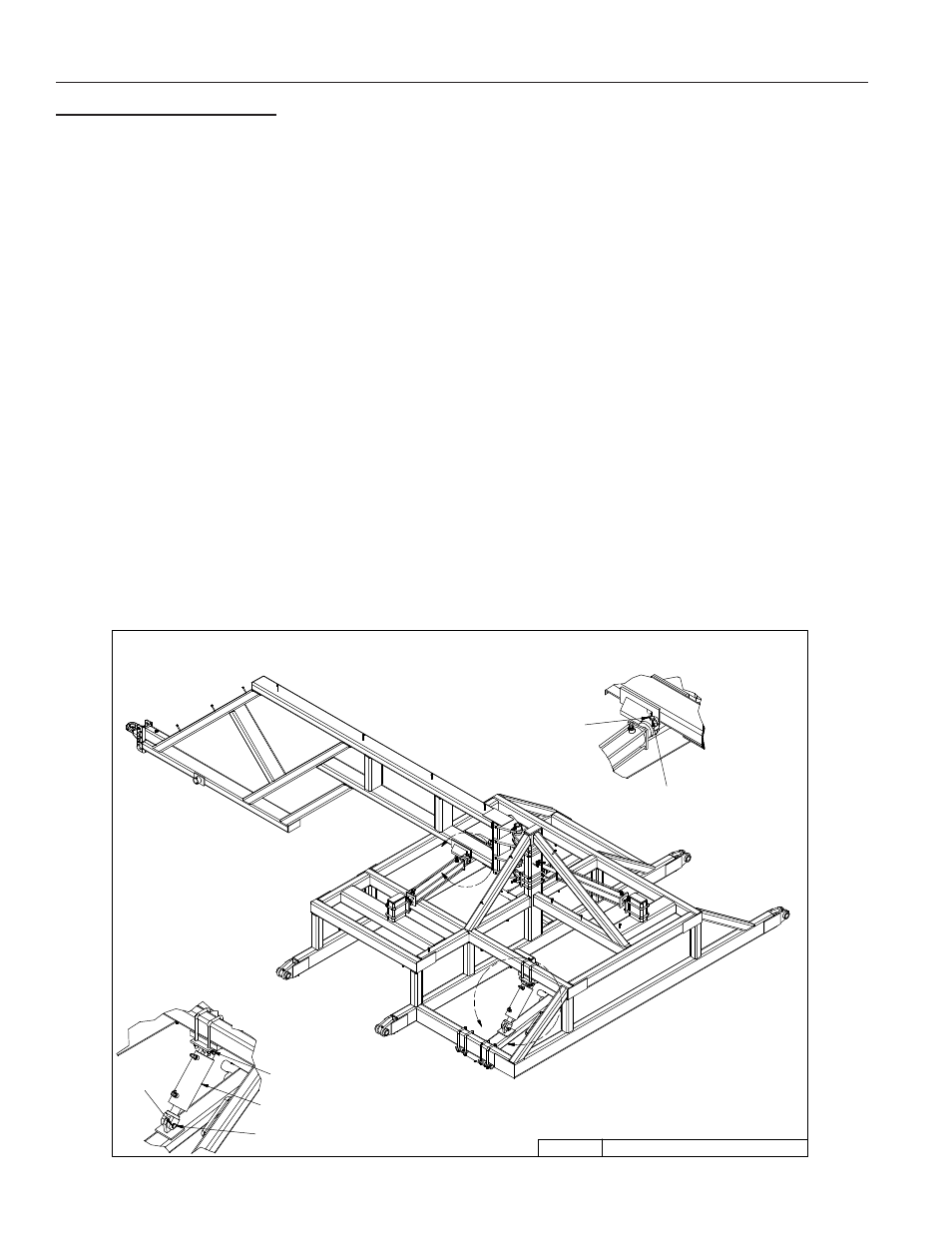

Hydraulic Installation

H1. Install Hydraulic components as shown in Figure 12 provided.

A.

Leave enough slack at the hitch pivot to allow folding machine without stretching or

pinching hydraulic hoses.

B.

Secure hoses with nylon ties and clamps provided. Do not over tighten clamps

H2. Block the hitch hydraulic cylinders so the rods can extend 32 inches without contacting any

obstructions. Fully extend and retract cylinders 3 times to insure all air is purged from the

cylinders.

H3. Fully retract the left cylinder, which will fully extend the right cylinders as shown in the draw-

ing below.

H4. Swing the hitch to the field position. Transferring the weight of the hitch from the transport

to the field position may cause the machine to shift. Use caution during this step.

H5. Install the pin in the rod end of the left cylinder. This will set the correct position of the hitch.

H6. Position the right cylinder to the hitch. At this point the hole in the rod end of the left cylin-

der may not line up with the hole in the hitch. Install the provided shims (8P6020) so the

hole in the rod of cylinder lines up with the hole in the hitch. The amount of shims used will

vary. Do not install so many shims that it pushes the hole in the rod of the cylinder past the

center of the hole in the hitch. Installing the pins with to many shims behind the pivot will

cause undo stress on the cylinder. It may be necessary to cycle the hydraulics a minimum

amount to get holes to line up perfectly.

H7. Level the cylinders and tighten the hardware on the pivots.

2-14

Figure 11