Maintenance & service, Troubleshooting, Maintenance & service -4 troubleshooting -4 – Summers 3-Rank Superweeder User Manual

Page 50

7-4

SECTION 7 – OPERATION - ALL MACHINES

MAINTENANCE AND SERVICE

LUBRICATION

Grease fitting locations and lube frequencies:

Daily:

2 on each knuckle

Daily:

1 on hinged joint on hinged wing machines

Daily:

Auto-Fold pivots

Weekly:

1 on each transport wheel axle

Weekly:

1 on each pivot tube where center section

attaches to hitch

Periodic:

Repack wheel bearings. Check tightness of

all hardware.

Lubricate these fittings with a good grade of general

purpose grease.

Over Winter:

Coat extended hydraulic cylinder rods with

grease to prevent corrosion.

TIRE INFLATION

Listed below are recommended tire inflations:

Hitch Tires:

11L x 15 - 36 PSI

14L x 16.1 - 30 PSI

Wing Support Tires:

7.60 x 15 - 24 PSI

11L x 15 - 24 PSI

Transport Tires:

7.60 x 15 - 40 PSI

11L x 15 - 36 PSI

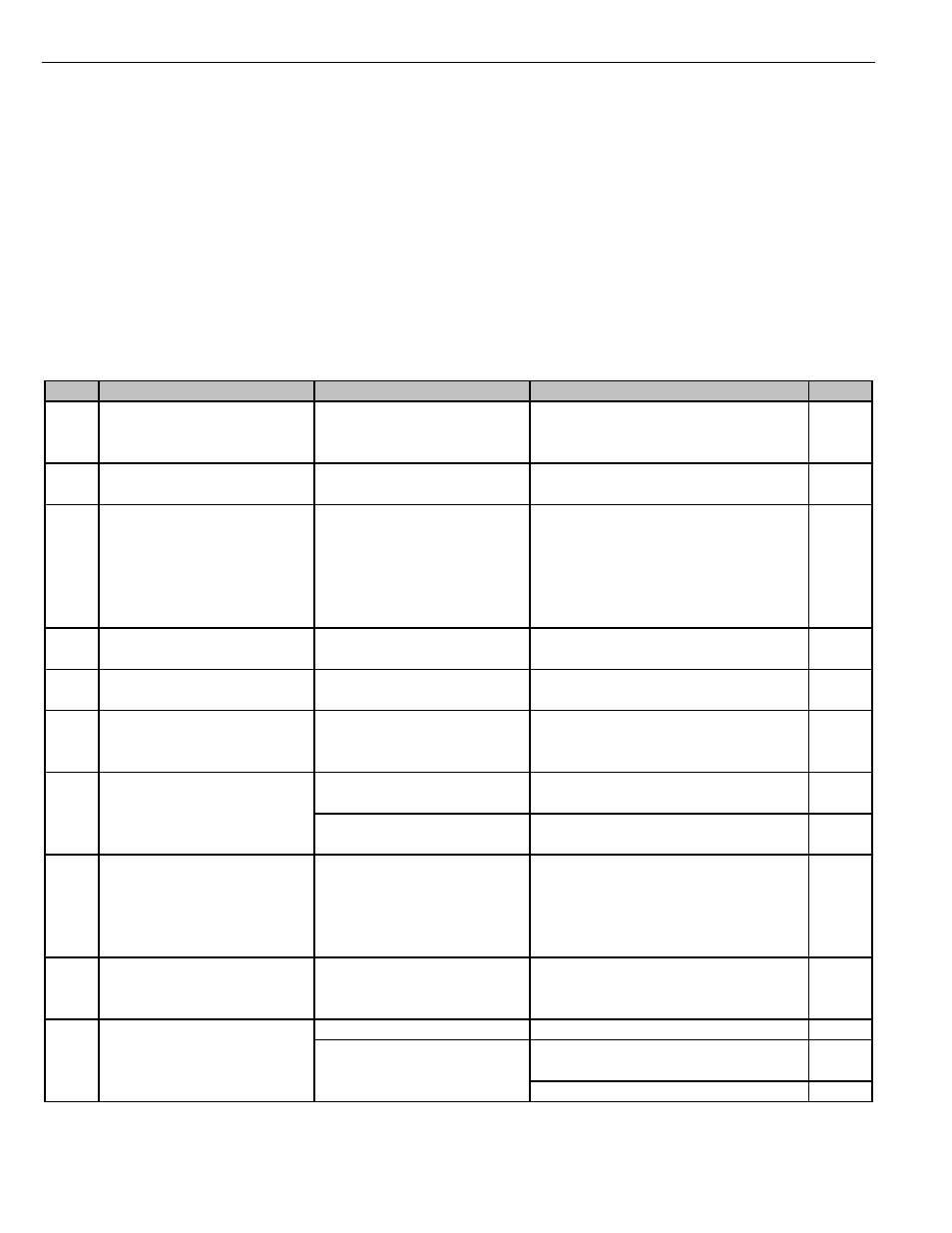

NO.

PROBLEM

CAUSE

CORRECTION

PAGE

1.

Light main hitch.

Transport wheels located to

far back on wing tubes.

Relocate transport wheels farther

ahead on wing tubes. Use wing tube

jack bracket.

1-2

2.

Wings trail too far apart in

transport position.

Insufficient transport wheel

toe-in adjustment.

Adjust transport wheel toe-in screw

for desired trailing position.

7-1

3.

Lowers to field position in a

fast or jerky motion.

Hydraulic restrictor valve

missing or installed

backwards in hydraulic

return line.

Install restrictor valve in hydraulic

return line so flow is restricted when

machine is lowered.

2-5,

2-6,

3-7,

3-8,

4-9,

4-10

4.

Wings of machine bounce

excessively.

Improper support tire

inflation. Problems 5 & 6.

Inflate support tire to proper

pressure.

7-4

5.

Wings are not pulling evenly

in field position.

Cable pull brackets are

improperly located.

Relocated cable pull brackets until

wings slightly lead the center.

-

6.

Harrow sections not riding

level. (Culti-Harrow Only)

Top pull chains are

improperly adjusted.

Adjust top pull chains by placing in

different adjustment hole on lift arm.

2-3,

7-2

Hydraulic cylinder leaking.

Replace or repair cylinder.

8-15,

8-16

Tractor hydraulic circuit not

holding pressure.

Repair tractor valve

-

8.

End harrow sections riding

up on wing support tires

while turning corners. (Culti-

Harrow Only)

Turning too sharp.

Replace end section top pull chain

with a solid pull strap, or: slide a 9"

length of 1-1/2" standard pipe over

top pull chain.

2-3,

7-2

9.

20' hitch Auto-Fold arms do

not fold into transport

position.

Improper pivot bracket

adjustment.

Adjust pivot bracket with set bolts

and jam nuts.

6-1

Excessive field speed

Reduce field speed.

-

Adjust pull chains.

2-3,

7-2

Install optional spring pressure.

2-3

Pull chains improperly

adjusted.

7.

S-Tines on Superweeder

tend to rotate out of the

ground.

10.

Culti-Harrow Sections

jumping.