Transport wheels – Summers 3-Rank Superweeder User Manual

Page 21

3-3

Use CAUTION when making manual height adjustments. For Safety purposes, block equipment while working on it.

On the center two sections only, move the lower stop bolt and bushing to the front hole (Fig. 12). This will allow the sections

to raise more evenly.

To compensate for various soil conditions and tooth wear, the sections can be mounted in four different positions as shown

below.

TRANSPORT WHEELS

Install transport wheels as shown in figures 1 and 13. Secure with two 5/8” x 5-1/2” bolts, lock washers and nuts.

NOTE: Transport wheel brackets are made for left and right and are not interchangeable.

IMPORTANT: The positioning of the transport wheel assemblies on the wing tubes of the machine is very critical in determin-

ing hitch weight. Moving transport wheel assemblies forward will increase hitch weight and moving rearward will decrease

hitch weight. See the “Warning Regarding Machines With Negative Hitch Weight” on page 1-2 for more information.

SECTION 3 – SET-UP INSTRUCTIONS — SUPERHARROW

Height Adjustment

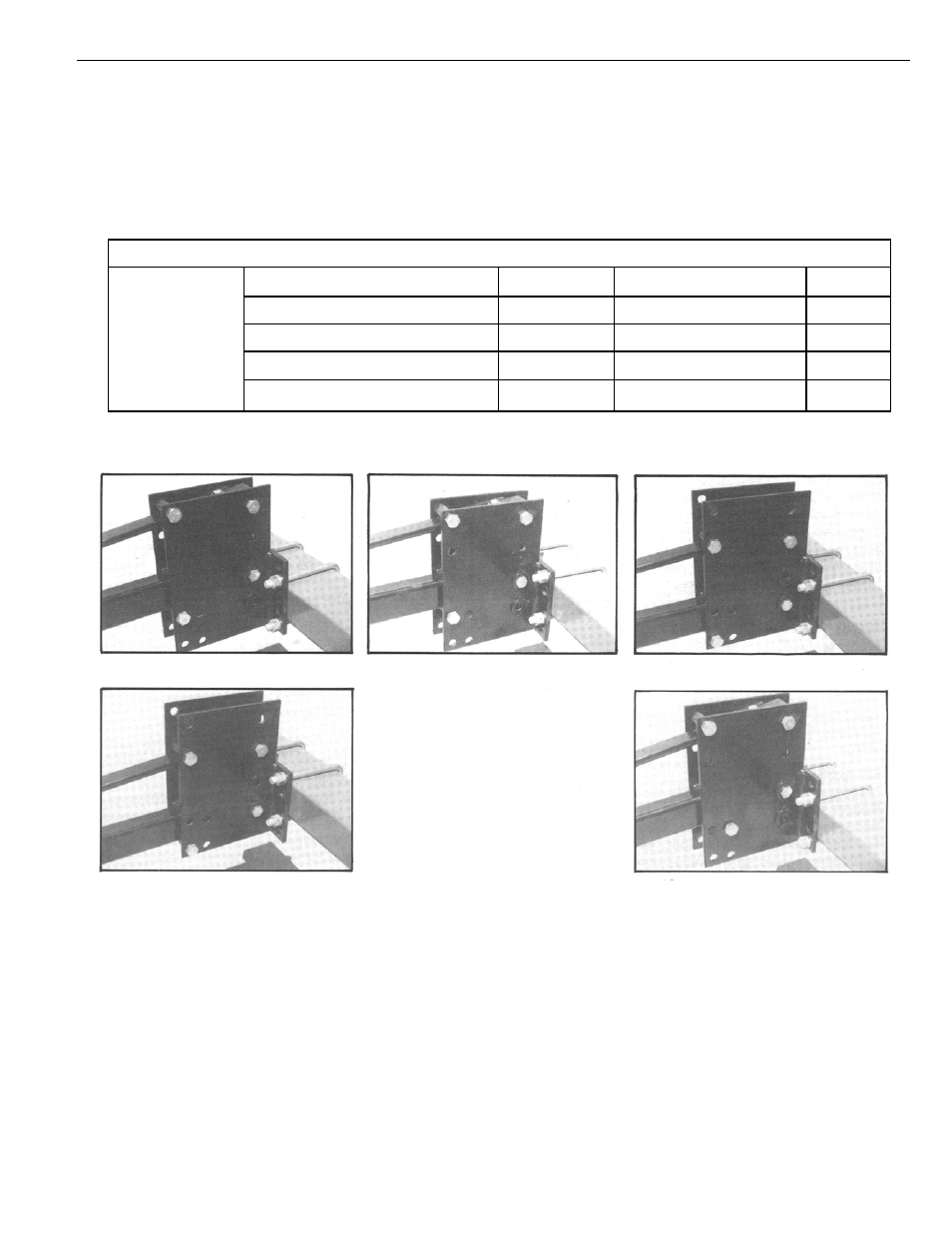

Suggested

Lift Arm Center

U-Bolt Plate Lift Arm / Spring Flat

Ref.

Initial Setting

3” Above Drawbar Center

Up

Up

Fig. 8

1-1/2” Above Drawbar Center

Down

Up

Fig. 9

Even With Drawbar Center

Up

Down

Fig. 10

1-1/2” Below Drawbar Center

Down

Down

Fig. 11

Fig. 8

Fig. 9

Fig. 10

Fig. 11

Fig. 12