0 quality control and assurance, 3 troubleshooting, 1 qualifying fusion procedure – Hawkeye PE Fittings User Manual

Page 5

Fabricated Fitting Fusion Procedure

Rev 0, Apr 08

5/5

other rejection criteria) allow the joint to cool, cut apart, and

restart fusion procedure from 6.2.1.

6.2.5 Hold

Hold the pipe ends together until the fusion joint is cool to the

touch. Thicker wall pipe will take longer to cool than thinner

wall pipe.

When the joint is cool to the touch, the fitting and pipe can be

subjected to GENTLE handling. The joint should be allowed

to cool for a further 30 to 45 minutes before further

installation, pressure testing or any other action that will

impart stress to the joint.

6.2.6 Inspect

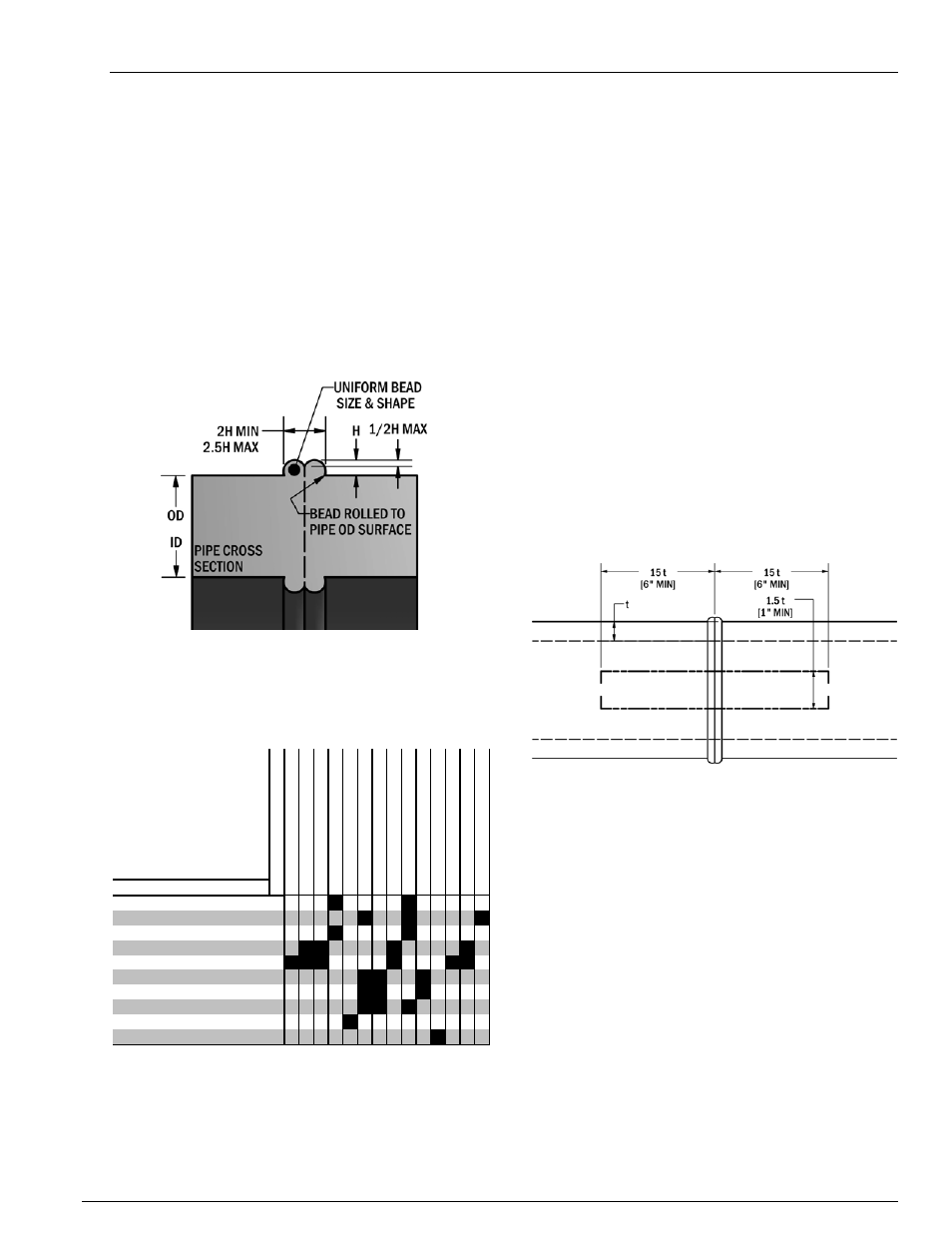

The bead should be symmetrical and uniform around the OD

and ID of the pipe and fitting. Refer to figure 6.2.6.1 for

successful fusion bead size and shape proportions.

Figure 6.2.6.1 Cross section of fusion joint with proper bead

6.3 Troubleshooting

Based on inspection of the bead, the following table lists

some possible causes of fusion failures.

Observation

x

x

x

x

x

x

x

x x

x

x

x x x

x

x x

x x

x

x x

x

x x

x

X

x

Flat Bead

Double bead groove too deep

Excessvie Double Bead Width

Equi

pment - Wor

n

Equi

pment - Cl

amp Sl

ip

Poss

ib

le Cause

Speckled or divotted bead

Beads too Large

Beads not fully rolled (deep 'V')

Beads not fully rolled (shallow 'V')

Beads too small

Bead larger than other

Bead not uniform around pipe

He

at - In

suf

fici

ent T

empe

rature

He

at - Ex

cessi

ve T

ime

He

at - Ex

cessi

ve T

empe

raure

Fa

cing - Incompl

et

e

S

oak Pre

ssu

re

- Ex

cess

iv

e

Mi

sali

gn

me

nt

Mater

ials - Di

ssi

mi

la

r

LH

C C

ontami

nati

on

Joi

ning F

or

ce - Insu

ffic

ie

nt

Joi

ning F

or

ce - E

xce

ssi

ve

He

ater - D

ef

ecti

ve

He

at - In

suf

fici

ent T

ime

Table 6.3

Bead sympotoms and possible causes.

7.0 Quality Control and Assurance

7.1

Qualifying Fusion Procedure

To qualify a fusion procedure, a sample joint must be

prepared and tested per ASTM D 2657 (or ERCB Directive

022 if fusion PE 80 or PE 100 pipe).

7.1.1 Sample

Joint

Prepare a sample joint. The each fusion end must be at least

15 wall thicknesses long, with a minimum length of 6 in.

7.1.2 Fusion

Follow the procedure outlined in 6.0 to obtain a sample

fusion. It is advised that the qualifying fusion process be

observed to ensure procedures are followed. Inspect the

completed joint against a known reference photo or sample

to confirm it is an acceptable joint.

7.1.3 Cool

The sample joint should be allowed to cool for no less that 60

minutes before continuing the test procedure.

7.1.4 Test

Strips

Cut, at minimum, three test strips from the sample joint. The

dimensions of the test strips are provided in figure 7.1.

Figure 7.1

Sample Strip dimensions (ASTM D 2657)

7.1.5

Examine and Bend Strips

Examine the weld cross section area for any voids or

contamination. An acceptable weld is monolithic, and there

should be no unbonded areas.

7.1.6

Repeat as Necessary

If the joint is unacceptable, repeat the process making

adjustments to parameters (as suggested in 6.3) to achieve a

successful fusion joint.

Qualifying fusions should be performed during changing

weather conditions and for each size of fusion performed.