Hawkeye Series 5000 EPRV User Manual

Page 4

C.) Series 5000 EPRV Maintenance

C1.) Inspect and Relubricate Sealing Gasket

C2.) Sealing Gasket Replacement

Hawkeye Industries Inc.

4

Generally, an emergency vent will not need lubrication as often as

a normal venting hatch. However, the device should be inspected

after any emergency venting occurrences. Relubrication and in-

spection shall be performed at least once per year to ensure the

continued performance of the vent.

Hawkeye factory-applies Dow Corning 4 Electrical Insulating Com-

pound to the vacuum and pressure gasket, and recommends the

same compound for any field relubrication.

►Excellent seal and release properties

►-57°C to 204°C

► Moisture Resistant

► 4.5% Bleed, 24 hr/200°C

► 1.4% Evaporation, 24 hr/200°C

► Non-toxic and odorless

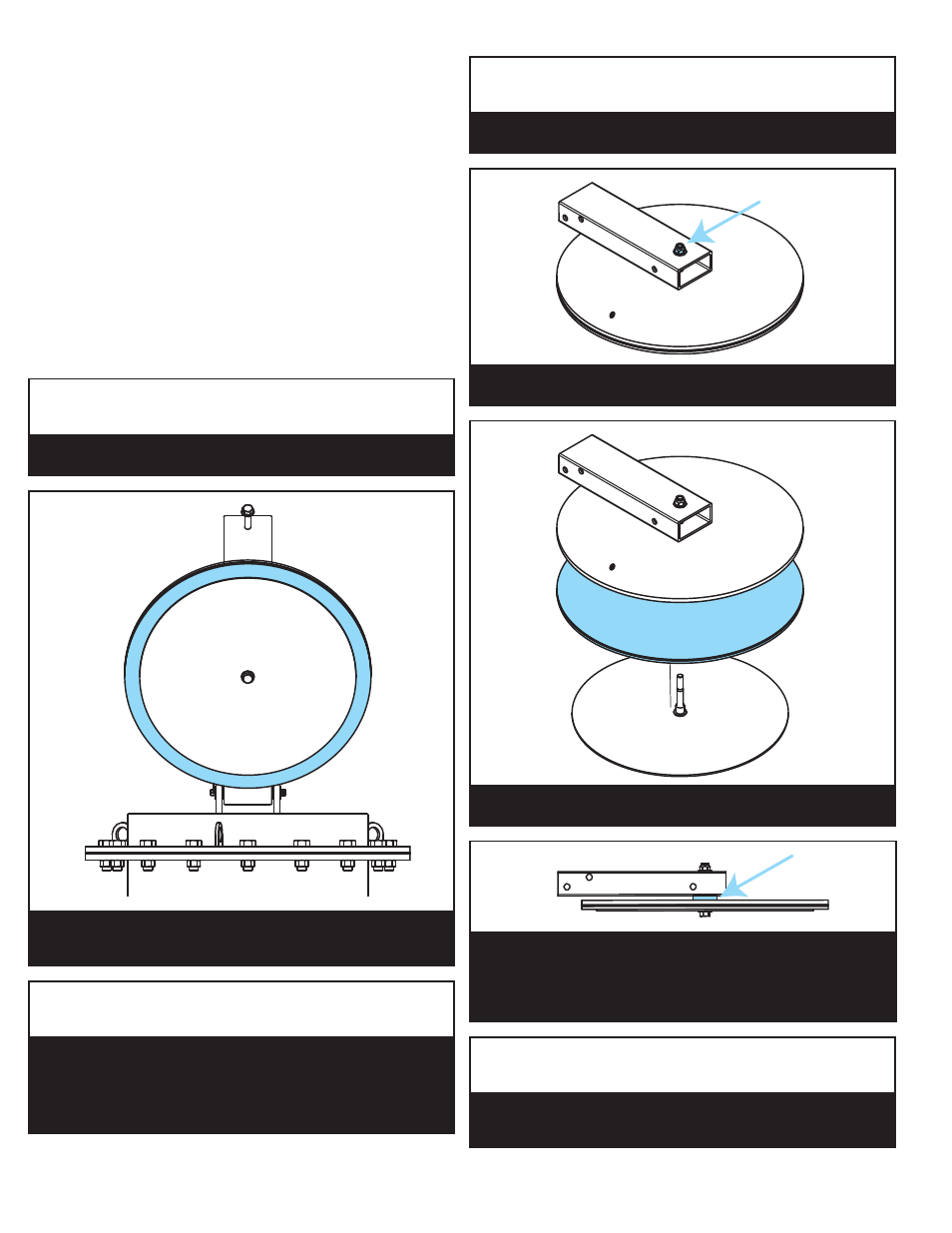

Follow steps 1 to 3 of Section B1, Man Way Access

1

Follow steps 1 to 3 of Section B2, Full Throat Man Way Access

1

Relubricate the sealing gasket with Dow Corning 4 Electrical Insulating

Compound or equivalent and return the vent to the operating position by

following these steps in reverse order and tightening the weight plate bolt

to 68 ft-lbs.

3

Lubricate the sealing gasket by following the relubrication instructions

above.

5

Inspect sealing gasket. Check for tears or debris. Compression setting (in-

dentation) in the sponge gasket is normal.

2

Remove gasket retaining bolt on pallet.

2

Replace composite sealing gasket.

3

Tighten the gasket retaining bolt to until the rubber mount has been com-

pressed from 1/2" thick to 3/8” thick. Return the vent to the operating posi-

tion by following these steps in reverse order. Tighten the weight plate bolt

to 68 ft-lbs.

4

Seal Maintenance Complete.

Seal Replacement Complete.