0 troubleshooting, 0 troubleshooting table, 0 troubleshooting 9.0 troubleshooting table – ARI Armaturen TEMPTROL 774 EN User Manual

Page 15: Operating and installation instructions temptrol

Rev. 0040702000 1011

Page 33

Operating and installation instructions

TEMPTROL

®

8.0 Troubleshooting

In the event of malfunction or faulty operating performance check that the installation and

adjustment work has been carried out and completed in accordance with these Operating

Instructions.

If malfunctions cannot be eliminate with the help of the following table

“9.0 Troubleshooting table”, the supplier or manufacturer should be consulted.

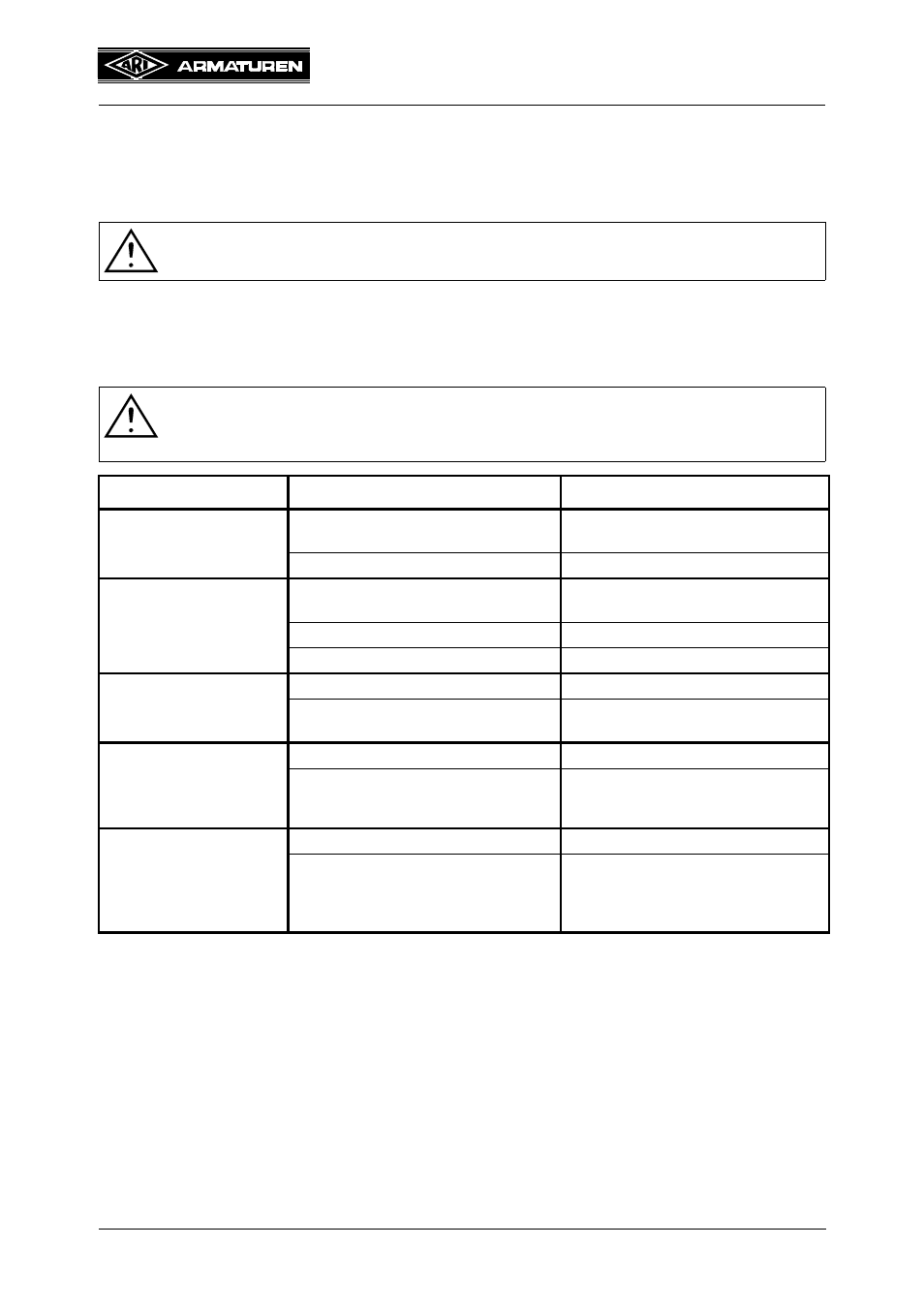

9.0 Troubleshooting table

-

ATTENTION !

It is essential that the safety regulations are observed when identifying faults.

ATTENTION !

- read item 10.0 and 11.0 prior to dismantling and repair work !

- read item 5.0 and 6.0 before restarting the plant !

Fault

Possible cause

Corrective measures

No flow

Valve closed

(manual control device)

Bring manual control device in com-

plete open position

Flange covers not removed

Remove flange covers

Flow to small

Valve not sufficiently open

(manual control device)

Bring manual control device in com-

plete open position

Dirt sieve clogged

Clean / replace sieve

Piping system clogged

Check piping system

Thermal closing valve:

Flow to large, no temper-

ature regulation possible

Leaky capillary tube system

Change the thermal control device

mounted against the allowed flow

direction

Mount valve in the correct flow direc-

tion

Thermal opening valve:

Flow to small, no temper-

ature regulation possible

Leaky capillary tube system

Change the thermal control device

mounted against the allowed flow

direction

Mount valve in the correct flow direc-

tion

Thermal mixing/diverting

valve:

no or inadequate mixing

or diverting function

Leaky capillary tube system

Change the thermal control device

mounted against the allowed flow

direction

Mount valve in the correct flow direc-

tion