0 troubleshooting table, Operating and installation instructions predu – ARI Armaturen PREDU 700 EN User Manual

Page 15

Rev. 0040701000 1714

Page 2-15

Operating and installation instructions

PREDU

®

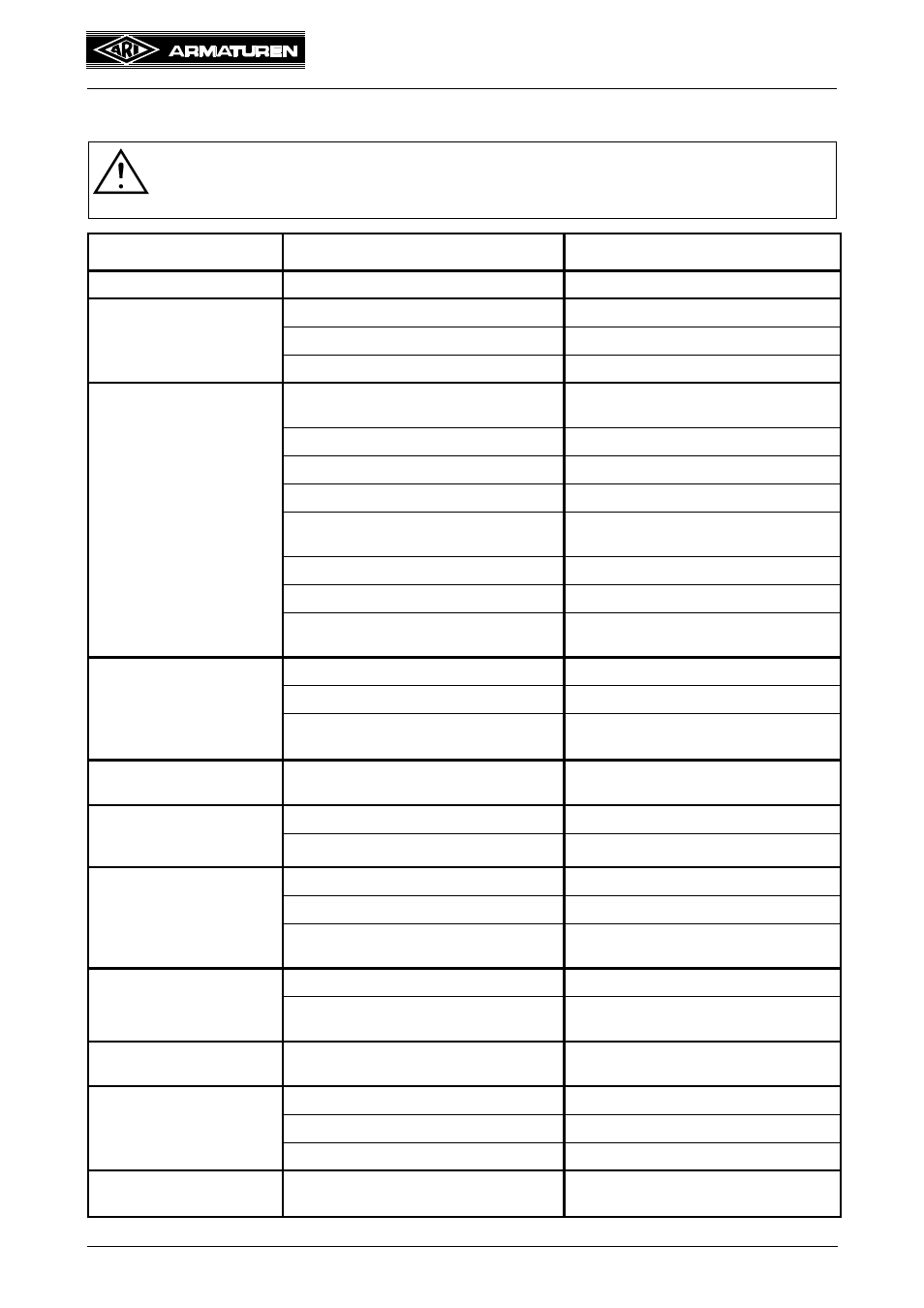

9.0 Troubleshooting table

ATTENTION !

- read point 10.0 and 11.0 prior to dismantling and repair work !

- read point 5.0 and 6.0 before restarting the plant !

Fault

Possible cause

Corrective measures

No flow

Flange covers not removed.

Remove flange covers.

Little flow

Dirt sieve clogged.

Clean / replace sieve.

Piping system clogged.

Check piping system.

Kvs value of valve unsuitable.

Fit valve with higher Kvs value.

Downstream pressure rises

quickly when the users are

turned off

Seat / Disc leakage, very dirty

Change valve or, if necessary,

seat/plug

Control line or flow restrictor blocked

Clean control line or flow restrictor

Diaphragm defect

Change diaphragm

Thread plug blocked

Open hole in the vent plug screw

Pressure balancing hole in the disc

blocked

Open pressure balancing hole

Balanced bellows defect

Renew balanced bellows

Valve in the control line closed

Open valve in the control line

Actuator not fitted proper

Loosen lock nut. Tighten actuator.

Fix lock nut.

Flange broken.

Damage during transport.

Replace pressure reducing valve.

Flange bolts not evenly tightened.

Replace pressure reducing valve.

Transfer of unsafe forces such as

bending or torsional forces.

Install free of tension.

Media comes out of the

vent plug hole

Diaphragm leaking.

Change diaphragm.

Downstream pressure can

not be adjusted in the full

capacity range

Valve laid out to small.

New layout of valve.

Valve setting is wrong.

Reset valve.

Valve doesn’t regulate

Control line or flow restrictor blocked.

Clean control line or flow restrictor.

Diaphragm defect.

Change diaphragm.

Control line is connected to the vent

plug hole.

Fix control line pipe to the control pipe

connection.

Downstream pressure

unstable

Flow restrictor not installed.

Install flow restrictor.

The ratio of upstream to downstream

pressure to high.

Reduction over two stages. Install pres-

sure reducing valve in row.

Media exit out of the bon-

net (at the spindle leakage)

Sealing bellows defect.

Change sealing bellows.

Downstream pressure can’t

be altered

Manometer defect.

Change manometer.

Bonnet thread damaged.

Change bonnet.

Valve closed in the control line.

Open valve in the control line.

Valve stem moves in jerks. Valve plug slightly seized owing to solid

dirt particles.

Clean internals, change plug and

guide bush.