0 troubleshooting table, Operating and installation instructions astra, Plus – ARI Armaturen ASTRA Plus DN250-400 EN User Manual

Page 11

Rev. 0040105005 0212

Page 11

Operating and installation instructions

ASTRA

®

Plus

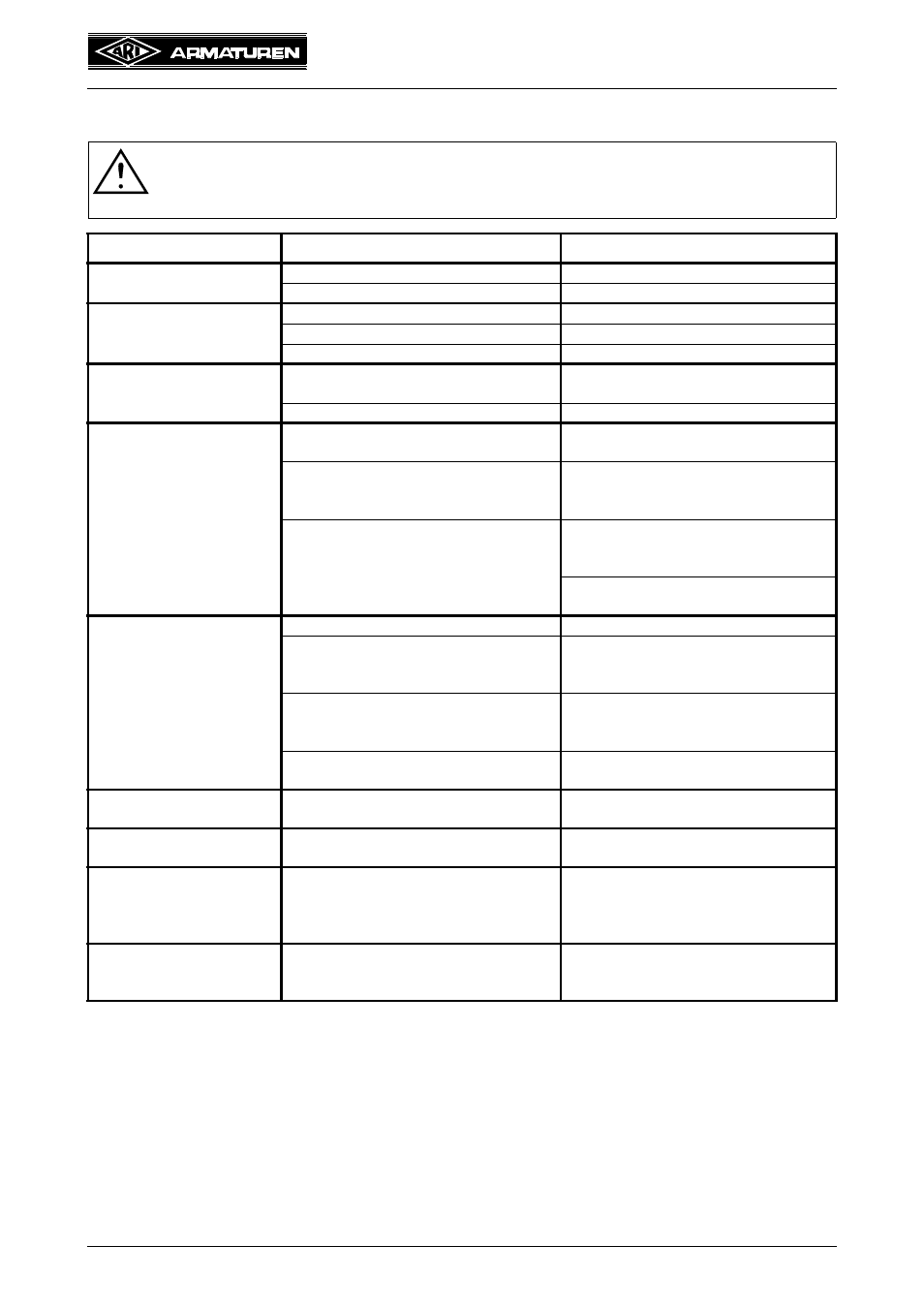

9.0 Troubleshooting table

ATTENTION !

- read point 10.0 and 11.0 prior to dismantling and repair work !

- read point 6.0 before restarting the plant !

Fault

Possible cause

Corrective measures

No flow

Valve closed.

Open valve.

Flange covers not removed.

Remove flange covers.

Little flow

Valve not sufficiently open.

Open valve.

Dirt sieve clogged.

Clean / replace sieve.

Piping system clogged.

Check piping system.

Valve difficult to move or

cannot be opened

Wrong direction of rotation

Turn in correct direction (anticlockwise

to open valve).

Safety stuffig box tightened to strong.

Loosen safety stuffingbox slightly.

Valve stem leaking

Bellows seal damaged.

Replace top of bellows seal at earliest

opportunity!

Gland screw (pos. 12) slack.

Tighten gland screw (pos. 12) until

leakage stops.

Replace top part at earliest opportunity!

Stuffing box gland DN250-500 (pos. 17)

slack (fig. 4).

Tighten stuffing box gland (pos. 17)

until leakage stops. -Hex. nut (fig. 4).

Replace top part at earliest opportunity!

If necessary, renew packing in stuffing

box seal (pos. 6). Observe warnings!

Leakage across valve seat. Valve not properly closed.

Pull hand wheel tight without tools.

Seat (pos. 1/1.2) / plug (pos. 3) dam-

aged by foreign particles.

(Fig. 3/4).

Replaced valve, consult supplier/man-

ufacturer.

Pressure difference too high.

Check system pressure and pressure

drop (max.

Δp = 16 bar up to DN125).

Reduce system pressure.

Medium contaminated

(suspended solids).

Clean valve.

Install dirt screen upstream of valve.

Valve with lift limiter cannot

be opened.

Lift limiter on stem stop has been tight-

ened.

Turn lift limiter upwards.

Flange broken between

valve and piping.

Bolts tightened unevenly.

Mating flanges not properly aligned.

Re-align piping and fit new valve!

Display does not show “0”/

“0” when valve is closed.

Display not fitted properly after pipe was

lagged.

Close valve, unscrew cap (pos. 19),

remove hand wheel and digital display,

set display to “0”/“0” and reassemble in

reverse order. (See point 5.2).

False data recorded.

False data displayed.

See point 5.2.

Observe operating instructions for

measuring instrument used.