Service, Ignition control system, System diagnostics – State SBL95 250NE A User Manual

Page 31: Electrical servicing

31

The installer may be able to observe and correct certain problems

which may arise when the unit is put into operation. HOWeVer,

it is recommended that only a qualified service agency, using

appropriate test equipment, be allowed to service the heater.

As preliminary step, check wiring against diagram, check for

grounded, broken or loose wires. Check all wire ends to be sure

that they are making good contact.

ignition Control system

before calling your qualified service agency, the following

checklist should be examined to eliminate obvious problems

from those requiring replacement or servicing.

• Check that “main gas shutoff valve” is fully open and that gas

service has not been interrupted.

• Check electrical supply to the water heater for possible blown

(or tripped) fusing or power interruption. Also check the 3 amp

fuse on the front of the digital thermostat (Fig. 2).

• Is the water temperature in tank below the thermostat dial

setting on the water heater thermostat (calling for heat)?

• It is possible that the high limit (e.C.O.) has functioned to shut

off the water heater. See page 7 - High limit Switch for reset

procedure. Contact your service agent if limit continues to

function to shut off water heater.

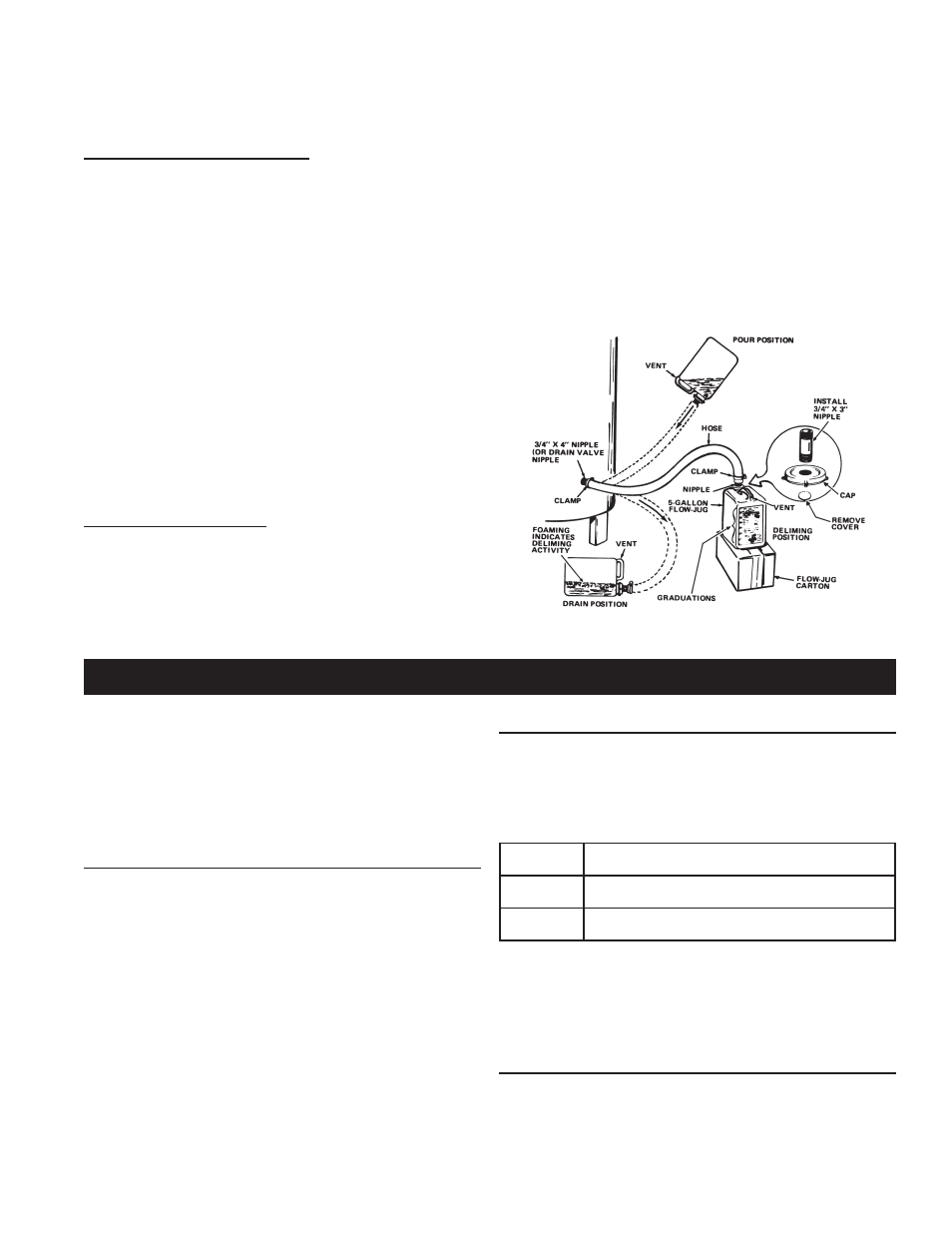

and pour the UN•lIMe into the heater.

7. lower container, you may have to place the container on

its empty carton to prevent the UN•lIMe from flowing back

into the container.

8. let UN•lIMe remain in the heater for 5 minutes and then

lower the container to the “Drain” Position, see Figure 27.

9. Deliming activity is indicated by foaming on the surface of the

UN•lIMe. If there is deliming activity, repeat steps 6 thru 8.

Normally, lime removal will be completed within one hour. Severe

build-up of lime may take longer than an hour to complete descaling.

note: To check UN•lIMe for continued use, place some scale

or white chalk in a glass with a small amount of UN•lIMe. If

the material is vigorously dissolved by the UN•lIMe, it can be

reused; if not, the UN•lIMe should be replaced.

figure 27.

9. Install the long plastic male adapter insert fitting into the

drain valve opening of heater after applying Teflon tape or

paste to threads. Tighten firmly by hand and use wrench or

adjustable pliers to check for secure connection. Do not over

tighten to avoid damage to threads and fittings.

Prepare the Up-N-Down Transfer Kit

The next step is the preparation on the Up-N-Down Transfer Kit,

if you have not already done so:

1. With the 5 gallon Up-N-Down container in the vertical

position, unscrew the plastic vent cap in the handle and

pierce the plastic membrane over the vent boss under the

cap to allow the container to vent.

note: If your container does not have the vent cap and

vent boss, drill a 3/16” hole in the handle. When you have

finished deliming you will be able to plug this drilled vent with

the stainless steel screw that is supplied with the kit.

2. remove the container’s cap and cut the plastic membrane

located in the 3/4” IPT opening in the cap. Take care to not

damage the threads.

3. Find the 3/4” male adapter, apply teflon tape to the threaded

end and screw it into the 3/4” IPT opening in the cap.

4. Put cap with male adapter back on the container and slide

3/4” hose over end of male adapter and fasten in place using

hose clamp provided.

Delime using Flo-Jug Method

5. Slide the hose clamp over end of hose and slide hose over

the male adapter in the water heater drain opening and

secure in place using hose clamp.

6. lift container to the “Pour” Position, see Figure 27, being

careful to keep the vent in the handle above the liquid level

serViCe

system diagnostiCs

Your water heater is equipped with an ignition control that

incorporates a diagnostic system to assist in troubleshooting the

water heater. The indicator codes on the ignition module are as

follows:

taBle 9.

2 FlASHeS Flame sensed without call for heat

3 FlASHeS Ignition lockout

Steady On

Internal control failure

If an internal control failure is indicated, replace the ignition

control.

Use this diagnostic system in conjunction with

“TrOUbleSHOOTING” and the “SeqUeNCe OF OPerATION”

to troubleshoot the water heater.

eleCtriCal serViCing

label all wires prior to disconnection when servicing controls.

Wiring errors can cause improper and dangerous operation.

Verify proper operation after servicing.