State SSX100 User Manual

Page 52

52

Multiple Appliance Installations:

In multiple water heater installations or in installations where

the installed water heater(s) share a common gas supply main

with other gas fired appliances; the supply gas pressures shall

be measured at each water heater with all gas fired appliances

connected to a common main firing at full capacity.

on multiple water heater installations the supply gas line regulators

shall be adjusted to provide gas pressure to each water heater

within the minimum and maximum supply pressure requirements

listed in Table 4 on page 13 with all gas fired appliances connected

to a common gas main firing at full capacity.

nOtE: A pressure drop of more than 1.5” W. C. (0.37 kPa) when

the main burner ignites is an indication of an inadequate supply

of gas and can lead to ignition failure, rough starts and/or rough

operation. If a drop of more than 1.5” W. C. (0.37 kPa) in supply

gas pressure occurs when the main burner ignites, ensure

the supply gas lines and regulator(s) are properly sized and

installed. See the requirements for Power Supply and Supply

Gas line on page 13. See Supply Gas line Installation on

page 37. ensure all requirements and installation instructions

are maintained.

MAnIfOLd gAs PREssuRE AdjustMEnt

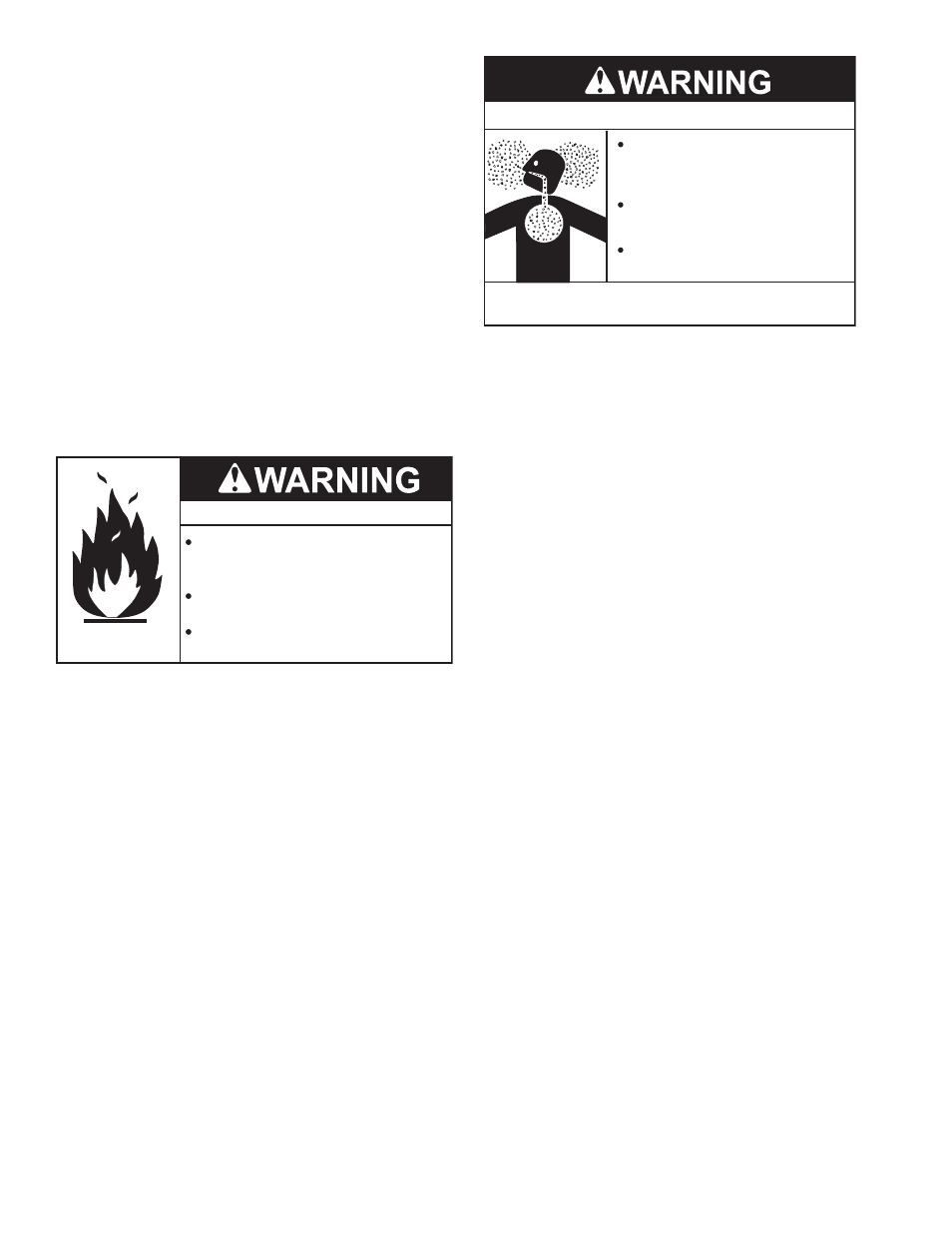

Fire and Explosion Hazard

Gas and carbon monoxide detectors are

available.

Overfiring could result in fire or

explosion.

Under no circumstances should the

input exceed the rate shown on the

water heater’s rating label.

Breathing Hazard - Carbon Monoxide Gas

Breathing carbon monoxide can cause brain damage or

death. Always read and understand instruction manual.

Under no circumstances should

the input exceed the rate shown

on the water heater’s rating label.

Overfiring could result in damage to

the water heater and sooting.

Gas and carbon monoxide detectors

are available.

ensure the "dynamic" supply gas pressure is above the minimum

requirements in Table 4 on page 13 before any adjustments are

made to the manifold gas pressure. Attempts to adjust manifold

gas pressure during periods of low supply gas pressure could

result in overfiring when the supply gas pressure returns to

normal. See Supply Gas Pressure Adjustment on this page.

Follow the steps below to adjust the manifold gas pressure on

SSF/SSX 100 models:

1. Follow the instructions for Initial Start up on page 50 to connect

manometers to the supply and manifold gas pressure taps

and to start the water heater.

2. remove the manifold gas pressure regulator cover screw,

see Figure 52 on page 51.

3. using a small flat tip screw driver turn the adjustment screw

clockwise to increase manifold gas pressure and counter

clockwise to decrease manifold gas pressure.

nOtE: Turn the manifold gas pressure adjustment screw

in small increments (no more than 1/4 turn) and allow the

manifold gas pressure to stabilize for several minutes before

making further adjustments.

4. replace the gas pressure regulator cover screw.

5. Cycle the burner on and off several times to check operation.