Fire and explosion hazard – State SSX100 User Manual

Page 51

51

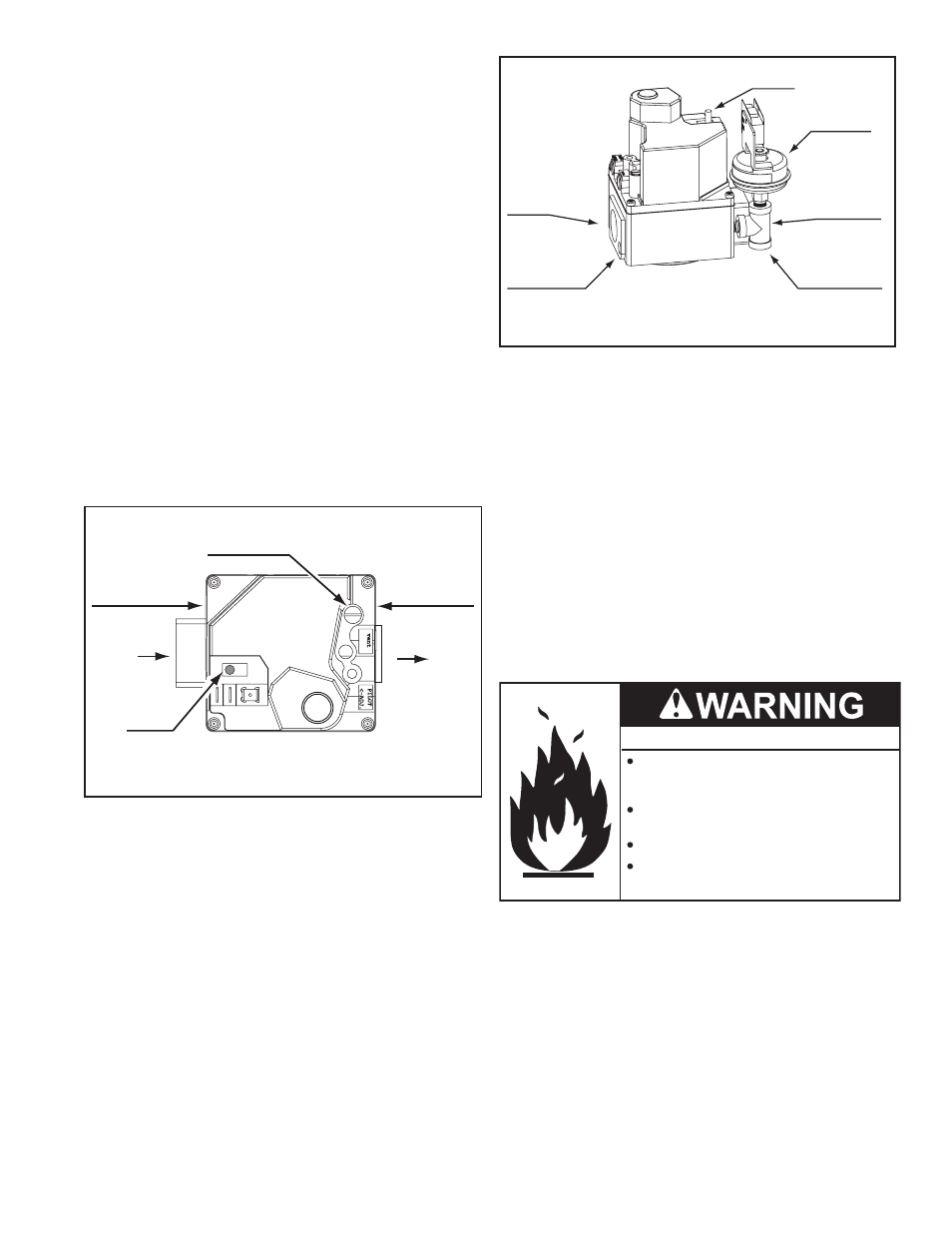

GAS VALVE SIDE VIEW

120,000 Btu/hr MODELS

MANIFOLD GAS

PRESSURE TAP

1/8’ NPT PLUG

SUPPLY GAS

PRESSURE TAP

1/8’ NPT PLUG

BOTTOM OF TEE

1/8” NPT

TEE FITTING

GAS VALVE

OUTLET

ON/OFF

SWITCH

LOW GAS

PRESSURE

SWITCH

figure 53

6. Compare the actual manifold gas pressure reading recorded

above to the required minimum/maximum values given

in Table 4 on page 13. Adjust manifold gas pressure as

necessary, see manifold Gas Pressure Adjustment on page 52.

7. record the supply gas pressure when the 24 Volt Gas Valve is

energized and the main burner is ignited. This is a “dynamic”

gas pressure reading; while the water heater is firing.

8. Compare the actual supply gas pressure reading recorded

above to the required minimum/maximum values given in

Table 4 on page 13. Adjust supply gas pressure as necessary,

see Supply Gas Pressure Adjustment on page 51.

9. When complete turn off gas to the water heater, see

instructions on page 53. Disconnect manometers and replace

all pipe plugs removed for testing. ensure all test port needle

valves opened during testing are completely closed.

suPPLy gAs PREssuRE AdjustMEnt

Fire and Explosion Hazard

Do not use water heater with any gas

other than the gas shown on the rating

label.

Excessive gas pressure to gas valve can

cause serious injury or death.

Turn off gas lines during installation.

Contact a qualified installer or service

agency for installation and service.

Supply gas pressure shall be measured while the water heater is

not firing (static pressure) AND while the water heater is firing at

full capacity (dynamic pressure).

If the supply gas pressure to the water heater is not between the

required minimum and maximum values given in Table 4 on page

13 adjust the supply gas regulator as necessary. Adjust the supply

gas regulator(s) per the regulator manufacturer’s instructions to

achieve the required “static” and “dynamic” supply gas pressure.

6. Connect one manometer (lower range) to an available test

port for manifold gas pressure to the main burner:

SSF/SSX 100 models: remove the 1/8 inch pipe plug from

the body of the gas valve on the outlet side and install a barb

fitting to connect the manometer sensing tube, see Figure 52

on page 51.

7. open the main Gas Shutoff Valve.

8. measure and record the supply gas pressure, this is a “static”

supply gas pressure reading; while the water heater is not

firing. Adjust supply gas pressure as necessary, see Supply

Gas Pressure Adjustment on page 51.

LIghtIng thE wAtER hEAtER

1. SSF/SSX 100 models: turn the on/off switch on the gas valve

to the "on" position, see Figure 52 and Figure 53.

2. Turn the water heater’s on/off switch to the “on” position.

3. Wait for the control system to complete its boot up sequence.

The Desktop screen showing the current operating Set

Point and Tank Temperature will be displayed on the control

system’s lCD when the boot up sequence is complete.

4. using the control system menus and uIm (user interface

module), change the operating Set Point to a setting higher

than the current tank temperature displayed on the control

system lCD plus the Differential setting to activate a call for

heating. See Control System operation on page 42.

ON

OFF

MANIFOLD GAS

PRESSURE REGULATOR

COVER SCREW

GAS VALVE TOP VIEW

120,000 Btu/hr MODELS

MANIFOLD GAS

PRESSURE TAP

1/8’ NPT PLUG

SUPPLY GAS

PRESSURE TAP

1/8’ NPT PLUG

INLET

OUTLET

ON/OFF

SWITCH

figure 52

5. record the manifold gas pressure when the 24 Volt Gas Valve

is energized and the main burner is ignited, the animated gas

valve icon will be displayed on the Desktop screen of the

control system’s lCD when the control system energizes the

24 Volt Gas Valve, a animated flame icon will appear when

main burner ignition is successful, see the Status Icons

descriptions in Table 11 on page 43.