Application example – Sandvik Coromant Machining carbon fibre materials User Manual

Page 45

Application example

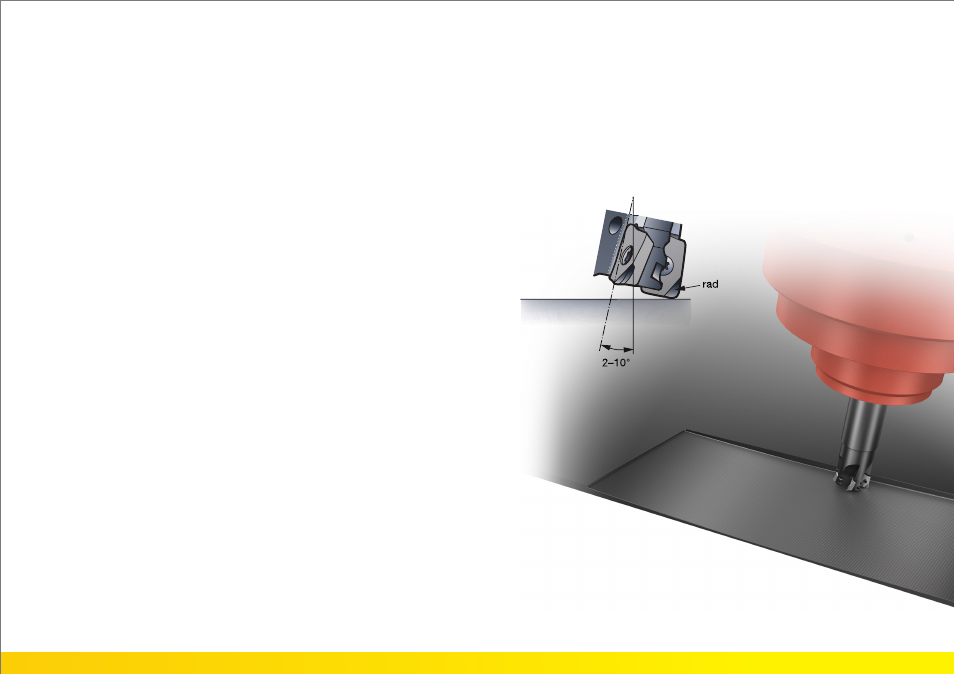

Sturtz milling: profiling of carbon fibre

Facts and demands:

•

-

Tilting of tool 2-10 degrees

-

High rpm and feed rate

-

Primary structure carbon fibre

-

Hand held pneumatic machine design

-

2D and 3D feature solutions

-

Good surface finish and dimensions

Solutions

•

-

CoroMill 390

-

Cutter: R390-032A32-11H

-

CD10 PCD inserts (3mm modied radii)

Cutting data

•

-

Vf: 1800 mm/min

-

2mm depth of cut.

-

5 degree sturtz angle.

-

fz: 0.2mm/tooth

Suitable process for large areas of shallow curvature, i.e.

•

many aircraft wing and fuselage components.

SANDVIK COROMANT USER’S GUIDE - COMPOSITE SOLUTIONS

45