Hole requirements – Sandvik Coromant Machining carbon fibre materials User Manual

Page 25

Hole requirements

Stacked materials

Common demands

•

-

Cpk>1,33

-

Ra<3,2 in carbon fibre

-

Ra<1,6 for Aluminium and titanium

-

Hole tolerance: +/- 20 µm to +/- 40 µm

-

No delamination or chipping in the hole exit

-

No chip erosion on the carbon fibre from the metallic stacked material

Criteria

•

-

Chips evacuation

-

Lubrification through the center

Dimension control

•

-

Holes are commonly pre-drilled

-

Finish hole size produced with one shot solution if possible

-

Reamer to be used when high demands on finish and size control

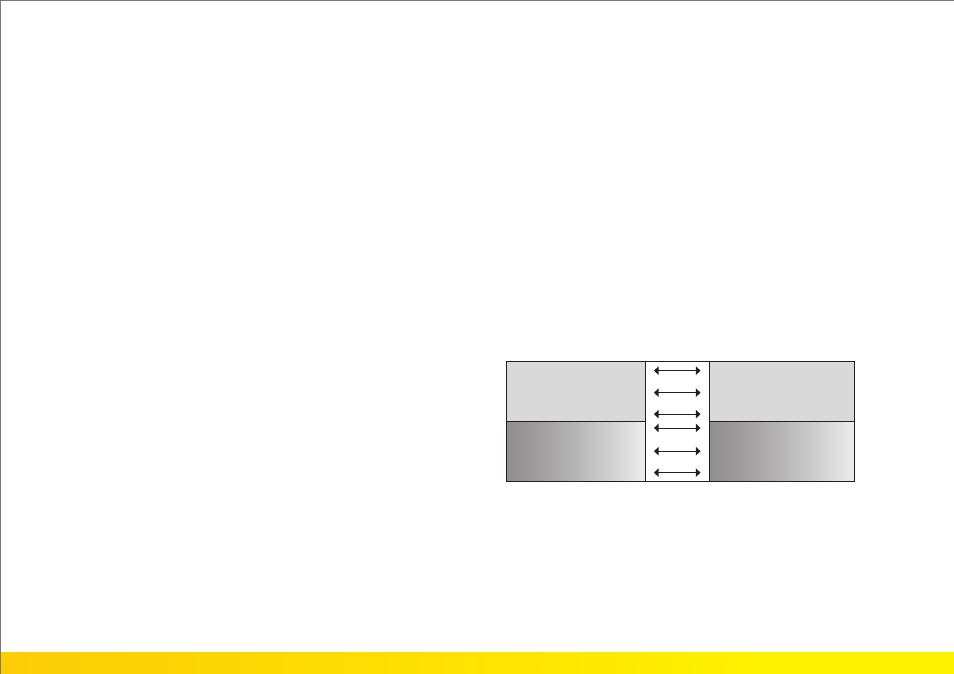

Holes are usually measured as diagram shows above every 90 degree

Material 1

Material 2

2 mm in from Entrance

Middle of material

2 mm from Exit

2 mm in from Entrance

Middle of material

2 mm from Exit

SANDVIK COROMANT USER’S GUIDE - COMPOSITE SOLUTIONS

25