Machining strategies – Sandvik Coromant Machining carbon fibre materials User Manual

Page 29

Machining strategies

CFRP

•

-

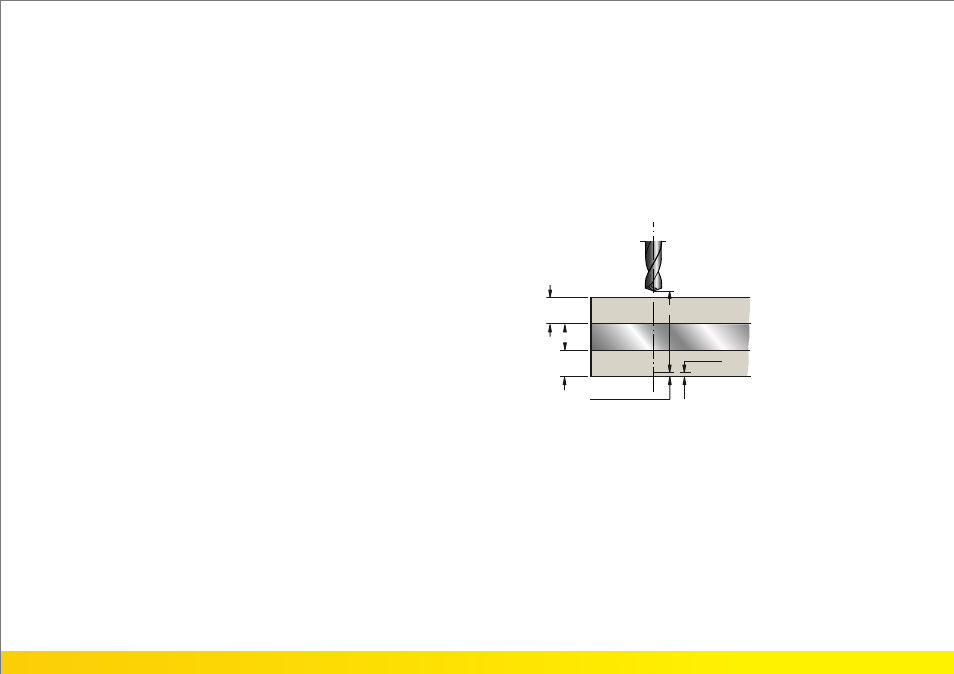

Quality must be checked both at hole entry and exit: different cutting

conditions may be needed.

-

Quality at exit is usually more difficult to achieve due to cutting forces.

Stacked materials

•

-

Cutting speed on a stacked metallic material, such as titanium, usually

needs to be lower than the CFRP.

-

The best cutting condition, for the metallic material, may be too slow

for good productivity on the composite material. Therefore variable cutting

data can be favourable.

feed rate: 0.15

2 mm

feed rate: 0.05

10

10

10

-

Entry layer

-

Mid layer

-

Exit layer

Application example =

Entry layer : CFRP

Mid layer : Al or Ti

Exit layer : CFRP

SANDVIK COROMANT USER’S GUIDE - COMPOSITE SOLUTIONS

29