Quality issues in cfrp – Sandvik Coromant Machining carbon fibre materials User Manual

Page 23

Quality issues in CFRP

Quality is not easily assessed:

•

-

there is no chip to look at

-

roughness measurement is not significant

-

damage can be not visible (delamination)

The main indicator is the hole quality

•

(and tool conditions)

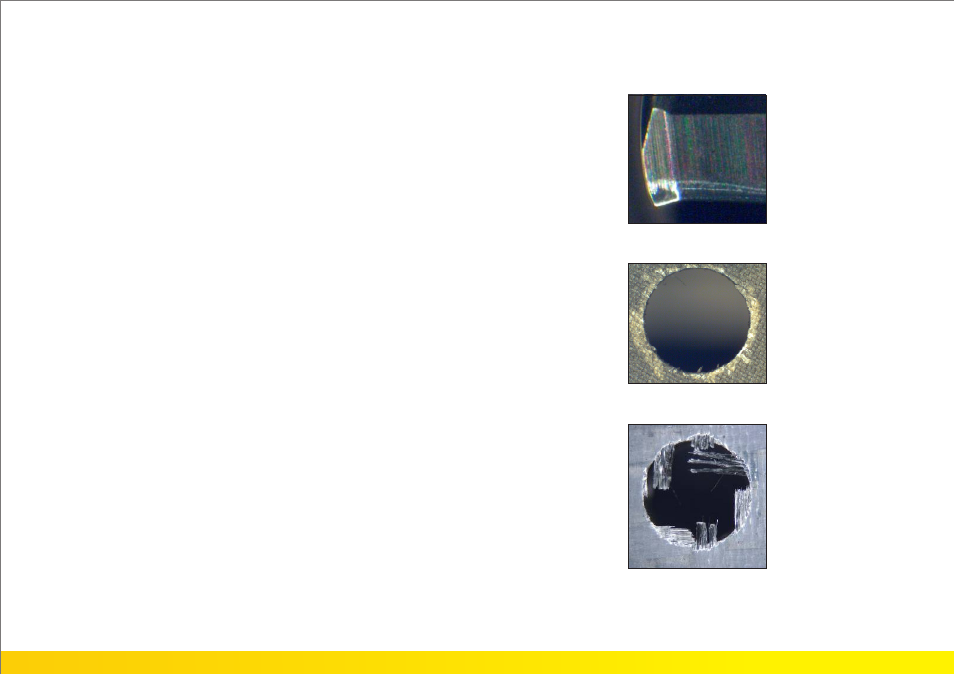

Delamination

•

-

Separation of the bottom layer(s) due to the “thrust” of the drill

Splintering

•

-

Residual fibres in the interior of the hole, due to poor cutting action

Delamination

Splintering/fraying

Tool wear on cutting edge

SANDVIK COROMANT USER’S GUIDE - COMPOSITE SOLUTIONS

23