Parts and service, Troubleshooting, Specifications caution – Dee Zee 123000-06 User Manual

Page 2

PARTS AND SERVICE

The Rotary Hand Pump is compatible with gasoline (up to 15%

alcohol blends such as E15), diesel fuel (up to 20% biodiesel blends

such as B20), kerosene and up to medium weight oils.

Construction:

Lightweight, die-cast aluminum housing.

Stainless steel shaft. Fluorocarbon

seals. Cast iron rotor and carbon vanes.

Built-in anti-siphon vent.

Pumping Capacity: Up to 10 gallons (38 litres) per 100

revolutions

Inlet:

1-inch NPT female

Outlet:

3/4-inch NPT female

Shipping Weight:

17 lbs. (7.7 kg)

Hose and Nozzle:

3/4-inch x 8 foot (2.4m) Buna-N

statically grounded hose.

Aluminum Alloy unleaded nozzle

Suction Pipe:

Plastic, adjustable from 22 to 40 inches

(55 to 102cm)

For warranty consideration, parts or other service information,

please contact your local distributor or the GPI Customer Service

Department, during normal business hours at:

1-800-835-0113

To obtain prompt, efficient service, be prepared with:

• the model number of your pump

• the serial number or manufacturing date code of your pump,

and

• parts descriptions and numbers

Reference the Illustrated Parts List for specifics on parts. For war-

ranty service, be prepared with your original sales slip or other

evidence of purchase date.

Do not return the pump without specific authority from the

GPI Customer Service Department. Due to strict regula-

tions governing transportation, handling, and disposal

of hazardous or flammable liquids, GPI will not accept

pumps for rework unless they are completely free of

liquid residue.

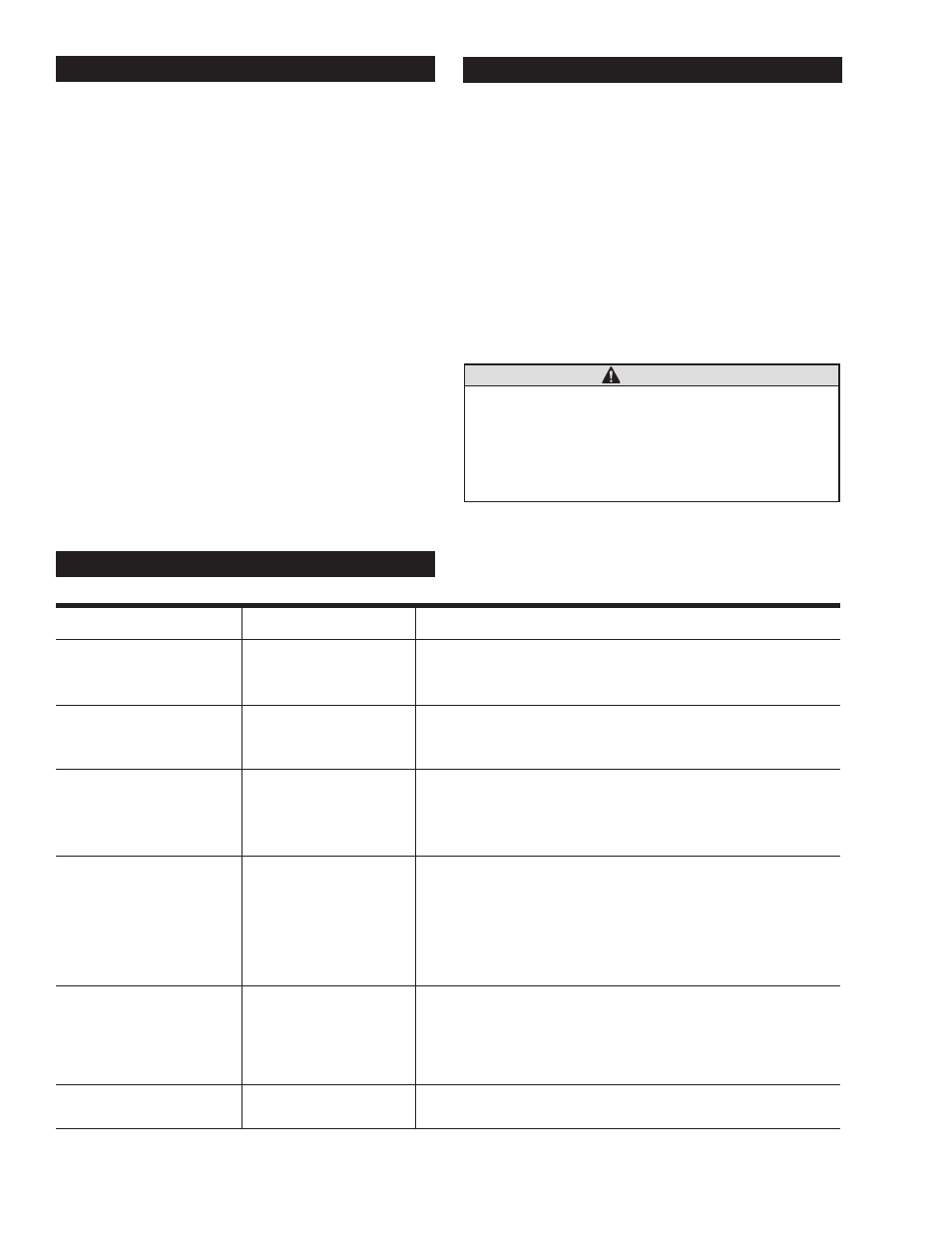

TROUBLESHOOTING

SYMPTOM

PROBABLE CAUSE

CORRECTIVE ACTION

A. FLUID LEAKS AROUND

1. Retainer loose

Tighten retainer screws.

SHAFT

2. O-ring worn

Check shaft O-ring for excessive wear. Replace Shaft Seal O-ring,

if necessary.

B. FLUID LEAKS AT ANTI-

1. Anti-siphon vent or

Remove vent cap. Loosen vent by turning counterclockwise. Remove

SIPHON VENT

O-ring damaged

vent and O-ring. Clean. To replace, seat O-ring on vent and screw vent

into place until bottomed out. Replace vent cap.

C. LOW FLOWRATE

1. Internal parts worn or

Remove coverplate and inspect for wear on vanes, coverplate, and all

debris in vane cavity

inside housing surfaces. Replace any scored parts.

2. Vanes cracked

Remove coverplate and inspect for chips or cracks on vanes. If

necessary, replace vanes.

D. PUMP FAILS TO PUMP

1. Suction pipe leak

Remove pump from tank and riser. Inspect the spacer and suction pipe

for wear or damage. Replace, as necessary, and install pump on tank.

2. Internal parts worn or

Remove coverplate and inspect for wear on vanes, coverplate, and all

debris in vane cavity

inside housing surfaces. Replace any scored parts.

3. Vanes cracked

Remove coverplate and inspect for chips or cracks on vanes. If

necessary, install Overhaul Kit or replace vanes.

E. HANDLE TURNS HARD

1. Debris in vane cavity

Remove pump from tank. Remove coverplate and inspect for debris in

OR PUMP SEIZED

cavity. Clean cavity, vanes, and rotor. Flush contamination from tank.

Assemble and install pump.

2. Internal parts worn

Remove pump from tank. Remove coverplate and inspect for damaged

necessary, install Overhaul Kit or replace vanes.

F. VANES STICKING

1. Debris in vane cavity

Remove coverplate. Use emery cloth to remove debris or corrosion in

vane slots. Apply lubricant (WD-40

®

) if needed.

SPECIFICATIONS

CAUTION