Mc Leod 4400 Series Truck Pull User Manual

Page 2

Review the following and make notes in your log book of your ‘New’ measurements.

Notes:

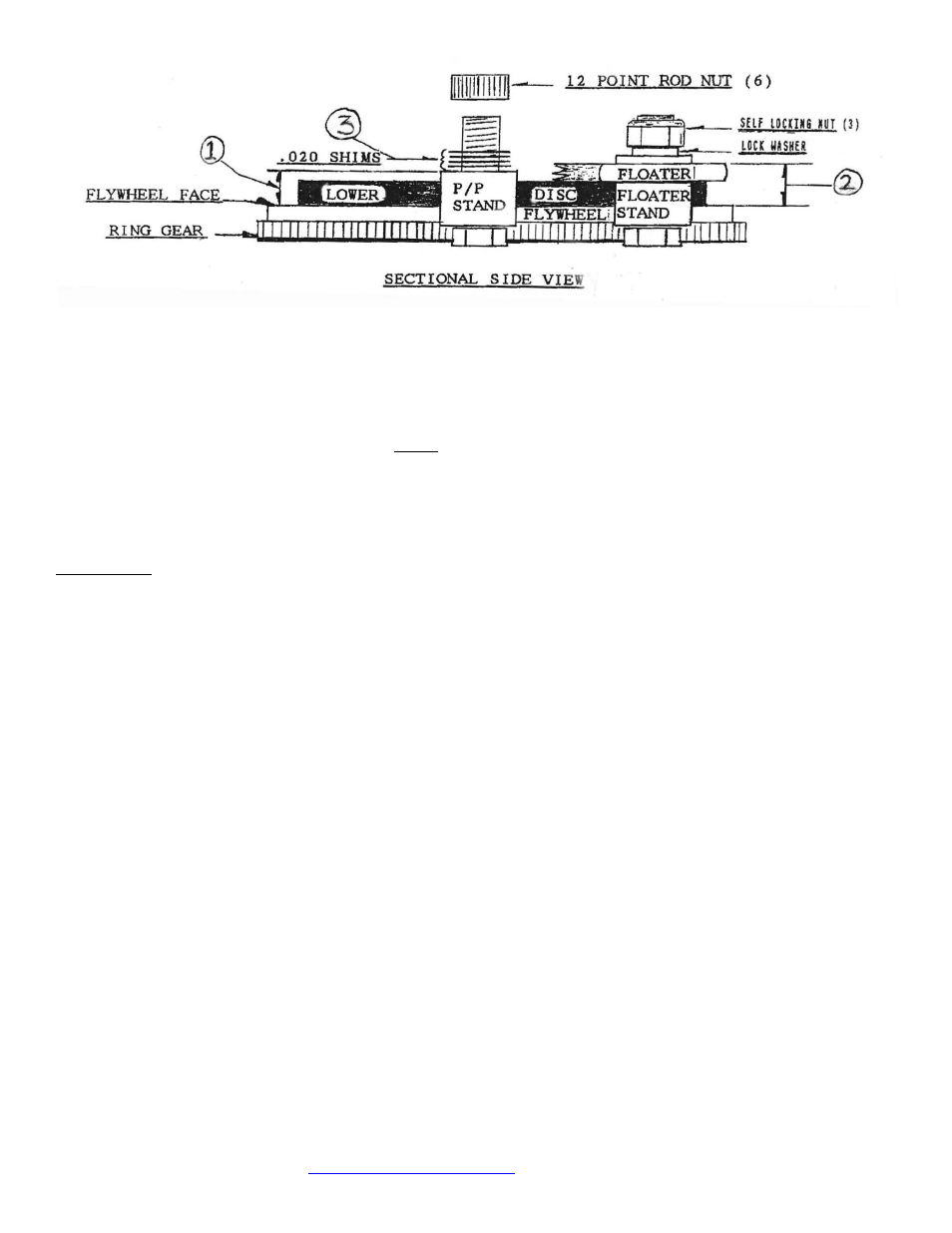

Step 1 – With bottom (lower) disc in place and floater installed, measure (with depth micrometer or

caliper) from the top of the pressure plate stand

Step 2 – Measure from the top of the floater to face of the flywheel. Note this number____________________.

to face of flywheel. Note this number___________________.

Step 3 – Add shims to make up the difference, so step #1 measurement equals step #2 measurement.

The shims under the pressure plate (on top of the 6 pressure plate stands) are called wear shims. As the

discs wear, you remove the amount of shim equal to the total wear of the discs.

Wear Shims

Example:

Starting disc thickness new is .330” each. If you have 2 discs you add .330” and .330” getting you a total

of .660” thickness. Now measure your used discs, let’s say one disc is .320” and the other is .317”. You

add .320 and .317 getting a combined total of .637”. Now subtract .637 from .660 (original starting

thickness) and the total wear is the amount of shim you must remove.

.660”(New thickness) minus .637” (Used thickness) equals .023” Total wear

In this case .023” is the amount of shim thickness you need to remove. This would be (1) .020” thick shim

from each stand. Now the unit is back to its original starting pressure.

The shims are approximately .020” thick. See shim removal chart:

Disc Wear

Remove

Disc Wear

Remove

.000” - .015”

0 Shims

.016” - .039”

1 Shim

.040” - .059”

2 Shims

.060” - .079”

3 Shims

And so on…

McLeod Racing, LLC 1600 Sierra Madre Circle Placentia, CA 92870 714.630.2764

I0022