Curb idle speed and mixture adjustments – Demon Fuel Systems 1563010VE User Manual

Page 9

9

Figure 11

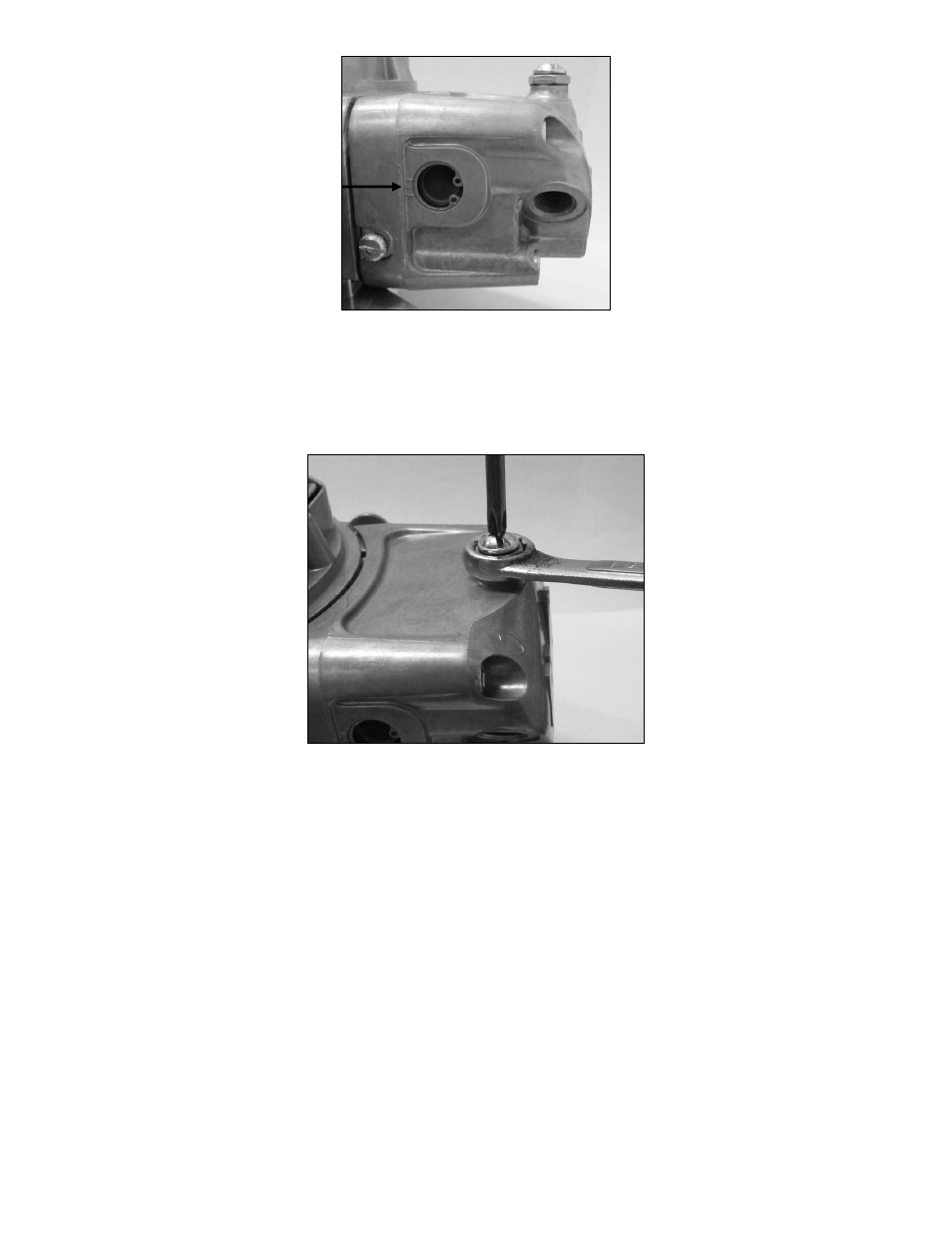

Changing the float level is accomplished by loosening the locking screw and rotating the adjuster nut

on the top of the bowl (Fig. 12). To prevent fuel leakage during the course of adjustments, only loosen

the locking screw enough to allow rotation of the adjuster nut. Rotating the adjuster nut clockwise will

lower the float level setting; conversely, rotating the adjuster nut counterclockwise will raise the float

level setting.

Figure 12

It’s important to note that, although increased fuel levels are immediately visible in the sight glass,

lowered fuel levels are not. The excess fuel in the bowl must be consumed before the fuel level can

stabilize at the new lower setting. When lowering the float levels, allow the engine to run for a few

minutes, or gently rev the engine until enough fuel is used to establish the new lower setting. For this

reason, setting the floats a little low (.500" or more) during the ‘dry setting’ procedure, then raising

them to the correct operating levels with the engine running, will prevent flooding at start up. It will

also shorten the time necessary to reach the correct setting. Experimenting with float settings a little

above or below the startup setting is also acceptable.

Curb Idle Speed and Mixture Adjustments

Fine tuning of the idle speed and mixture must be done with the engine at or near operating

temperature. A good rule of thumb is to not attempt adjustments until the engine has achieved 160

degrees water temperature. Adjusting the engine cold will usually result in a rich mixture at normal

operating temperature. It is also helpful to use a tachometer and/or a vacuum gauge for setting the

idle speed and mixture.