Demon Fuel Systems 1563010VE User Manual

Page 6

6

Connecting the Throttle Linkage

DO NOT RELY ON THE BASEPLATE LINKAGE AS A STOP! FAILURE TO USE A POSITIVE

PEDAL STOP CAN RESULT IN LINKAGE DAMAGE THAT CAUSES THE THROTTLE TO STICK

IN THE WIDE OPEN POSITION.

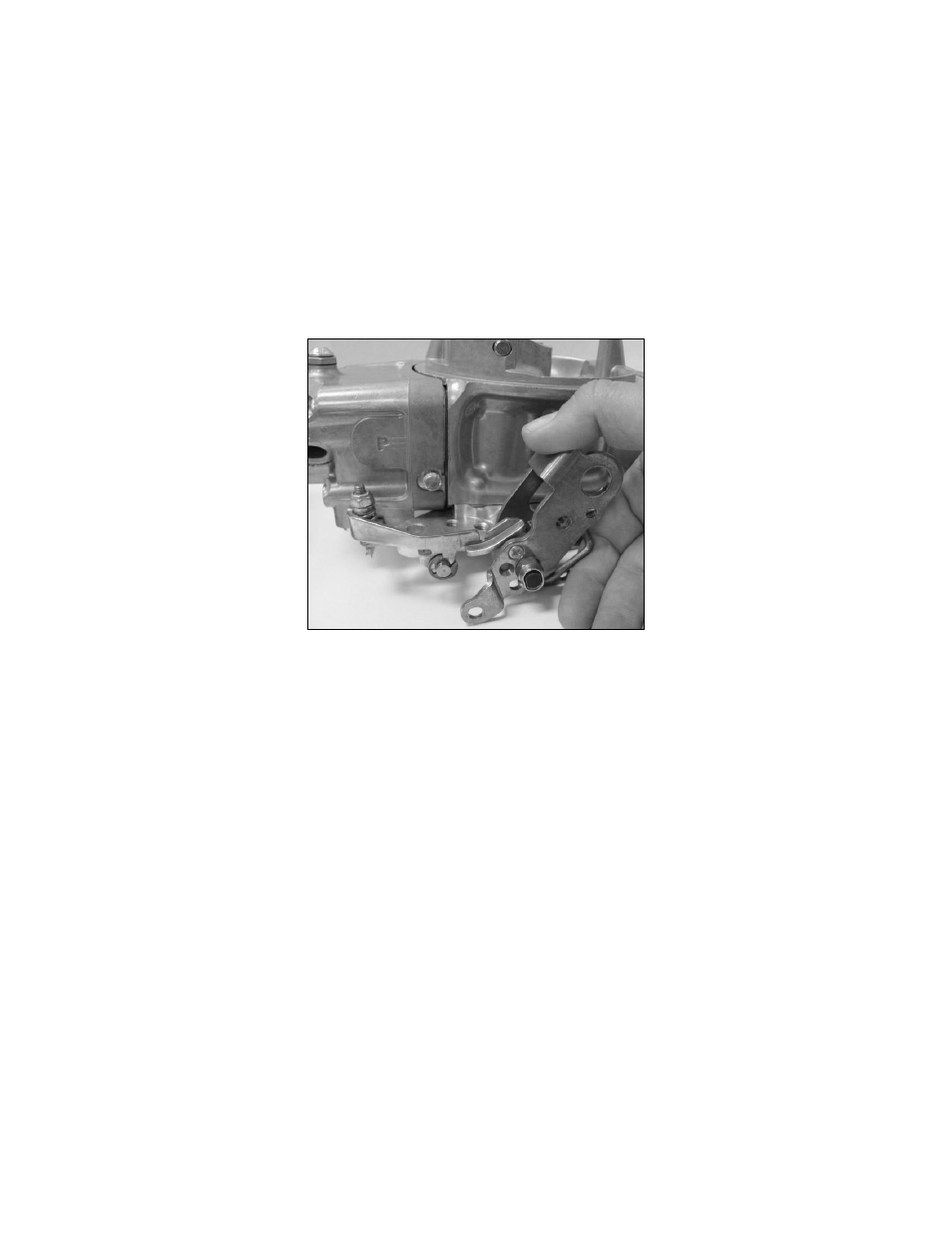

With the pedal held firmly against a stop, pull the carburetor to its wide open position (Fig. 8). Adjust

the linkage rod or cable to the proper length, and then attach it to the baseplate linkage. Remember,

the pedal should come against a positive stop, just as the carburetor gets to wide open throttle. With

the linkage rod attached to the baseplate, make sure the carburetor can return to its closed position.

Install your return spring(s), and check again for smooth operation to wide open throttle, and then

closed again.

Figure 8

Connecting the Fuel Lines

Always use lines and fittings that are built for automotive use, and compatible with your type of fuel.

Stainless steel braided, or push-lock type reinforced hose with AN swivel connections are

recommended on all fuel lines. Do not use thread lockers, sealing compounds, or Teflon tape on

AN flare fittings. When installing fuel bowl inlet fittings, use only the sealing washers or o-rings

provided with the fitting.

In most cases, a drop of oil to prevent thread galling

is all that’s necessary when installing pipe

threaded fittings. However, if a thread sealant is used on pipe fittings, use extreme caution to prevent

any tape or compound from entering the internal flow area. Remember to check for leaks when the

system is under pressure. If a leak is detected, replace the malfunctioning part. When installing new

fuel lines, be sure to flush the lines clear of any debris that might remain from the hose cutting or

assembly process.