Assembly instructions, Truss mount or channel strut mount, Max load: 15kgs / 35lbs – Clinton Electronics CE-CM-LX-17-B User Manual

Page 3

Assembly Instructions

Truss mount or channel strut mount

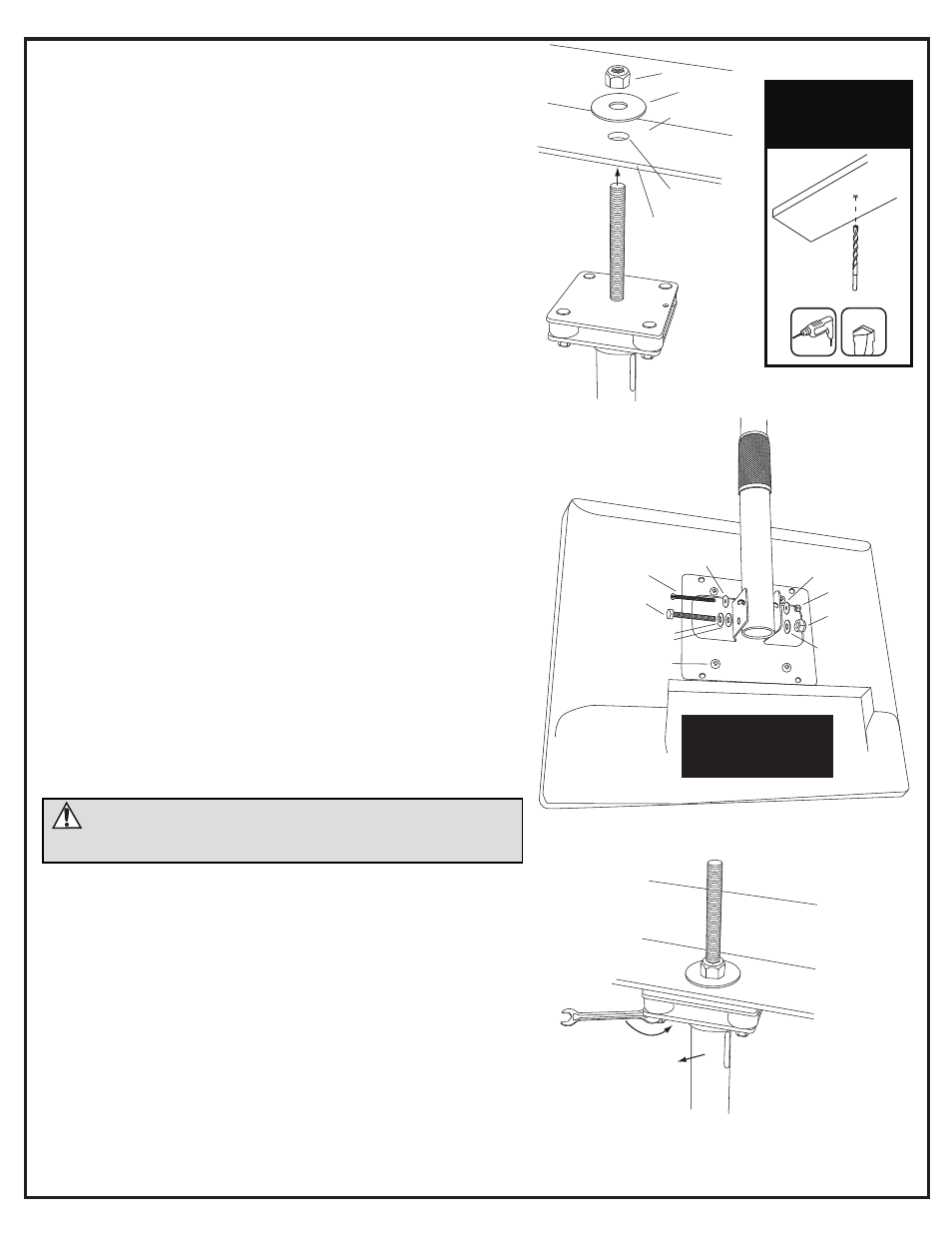

Securing Mount to Building:

1. Insert threaded rod between truss gap or into hole in channel strut.

2. Place 1/2” fender washer over the threaded rod and then 1/2” lock nut.

3. Tighten the 1/2”-13 lock nut using a 3/4” wrench.

7

/

16

10

1/2”-13 Lock Nut

Fender Washer

Truss or Channel Strut

M4 x 8mm

VESA screw

(4 places)

M4 Lock Nut

1/4”-20 Lock Nut

M4 x 45mm

1/4”-20 x 2”

M4 Washer

1/4” Washer

1/4” Washer

M4 Washer

Pole will move in

the direction of the

tightened bolt

1/4” Lock Washer

Min. Hole Size: 1/2”

Max. Hole Size: 5/8”

Min. Steel Thickness: 1/4”

Mounting LCD to Pole:

1. If your LCD is supplied with a VESA plate already mounted on the back, simply

ensure the four M4 screws are in place and tightened. If the mount is not already

attached, connect it using the supplied M4 x 8mm VESA screws (4-places).

*NOTE: Some installations may require running power and video cables

prior to attaching the LCD bracket to the pole. If this is the case, do so

before continuing to step 2.

2. Hold the LCD with attached bracket up to the end of the pole mount, and

line up the wings of the bracket to the holes in the end of the pole. Insert the

1/4”-20 x 2” bolt, lock washer, washers, and lock nut in place according to the

illustration on the right. You will use 7/16” and 10mm wrenches to fully tighten

in step 4.

3. Install the M4 x 45mm screw, washers, and lock nut into the upper slotted hole

according to the illustration on the right. You will use a #2 Phillips screwdriver

and a 7mm wrench to fully tighten in the next step.

4. Tighten the fasteners to secure the monitor at the desired angle.

*NOTE: Avoid overtightening which can cause the pole to indent.

7

/

16

10

1/2”-13 Lock Nut

Fender Washer

Truss or Channel Strut

M4 x 8mm

VESA screw

(4 places)

M4 Lock Nut

1/4”-20 Lock Nut

M4 x 45mm

1/4”-20 x 2”

M4 Washer

1/4” Washer

1/4” Washer

M4 Washer

Pole will move in

the direction of the

tightened bolt

1/4” Lock Washer

Min. Hole Size: 1/2”

Max. Hole Size: 5/8”

Min. Steel Thickness: 1/4”

Leveling the Pole

1. You can ensure the pole is plumb by tightening the 1/4”-20 lock nuts on the top

of the pole where it attaches to the structure using a 7/16” wrench.

2. Place a level on the pole and tighten the nuts that correspond to the direction

that the pole needs to move (see illustration on the right).

3. Check and adjust 2 adjacent sides of the pole until it is plumb in each direction.

7

/

16

10

1/2”-13 Lock Nut

Fender Washer

Truss or Channel Strut

M4 x 8mm

VESA screw

(4 places)

M4 Lock Nut

1/4”-20 Lock Nut

M4 x 45mm

1/4”-20 x 2”

M4 Washer

1/4” Washer

1/4” Washer

M4 Washer

Pole will move in

the direction of the

tightened bolt

1/4” Lock Washer

Min. Hole Size: 1/2”

Max. Hole Size: 5/8”

Min. Steel Thickness: 1/4”

Remove original

M4 x 8mm VESA

screw & replace with

M4 x 10mm screw

U-Bolt Cable Clamp

Cord Management Hole

Hold lower pole section and

turn counter-clockwise to loosen

Prevent display from falling by

holding lower pole section here

Secure assembly by turning collar clockwise:

hand tighten as snug as possible

CAUTION: This stand is intended for use only with the maximum weights indicated.

Use with products heavier than the maximum weights indicated may result in

instability causing possible injury. This product is intended to mount to a steel

support truss, or channel strut.

9/16”

If drilling is nec

essar

y,

U

se 9/16”

metal drill

bit t

o drill thr

ough st

eel

moun

ting sur

fac

e.

Max Load:

15kgs / 35lbs.

Remo

ve or

ig

inal

M4 x 8mm

VESA

scr

ew & r

eplac

e with

M4 x 10mm scr

ew

U-B

olt C

able Clamp

Cor

d M

anagemen

t Hole

Hold lo

w

er pole sec

tion and

tur

n c

oun

ter

-clock

wise t

o loosen

Prev

en

t displa

y fr

om falling b

y

holding lo

w

er pole sec

tion her

e

Secur

e assembly b

y tur

ning c

ollar clock

wise:

hand tigh

ten as snug as possible

CA

UTION

: T

his stand is in

tended f

or use only with the maximum w

eigh

ts indica

ted

.

U

se with pr

oduc

ts hea

vier than the maximum w

eigh

ts indica

ted ma

y r

esult in

instabilit

y causing possible injur

y. T

his pr

oduc

t is in

tended t

o moun

t t

o a st

eel

suppor

t truss

, or channel strut

.

9/16”

If drilling is necessary,

Use 9/16” metal drill

bit to drill through steel

mounting surface.