Machine cuts unevenly – Ashland I-130TS2 User Manual

Page 29

29

Machine cuts unevenly.

1. Cutting edges worn unevenly.

a) Replace cutting edges.

2. Improperly inflated tires.

a) Check air pressure in tires.

Apron closes slowly

or

Apron and push-off are not working well together.

1.

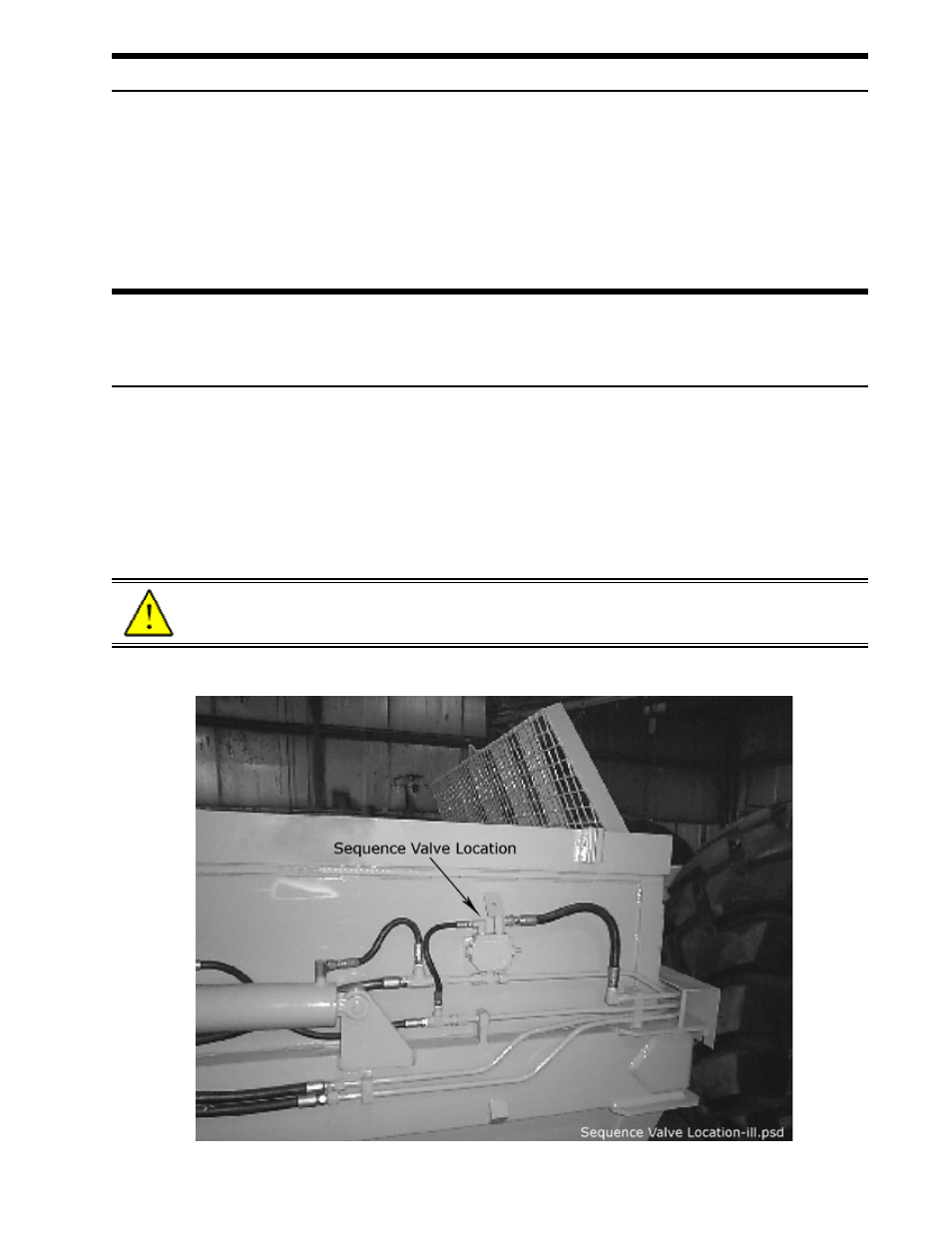

Sequence valve needs adjusting.

a) Remove acorn nut from end of sequence valve with a ½” wrench. Turn adjust-

ment screw, using a 4mm hex wrench, clockwise until front apron rises before

the push-off advances while the earthmover is empty. Turn the adjustment

screw an additional ¼ turn clockwise, then replace the acorn nut and tighten.

b) Torque check valve assembly and int. pilot plug to 25 ft-lbs maximum.

CAUTION! Overtightening check valve assembly and int. pilot plug will cause

internal damage to the sequence valve.

* Note: Check valve assembly may leak slightly when torqued to 25 ft-lbs.

- I-950 ver 1211 (38 pages)

- I-110TS2 ver 1111 (36 pages)

- I-110XL2 ver 1111 (34 pages)

- I-130TS2 ver 1111 (36 pages)

- I-130XL2 ver 611 (40 pages)

- I-155-TS2 ver 1111 (38 pages)

- I-155XL2 ver 0811 (34 pages)

- I-175XL2 ver 811 (34 pages)

- I-180TS2 ver 1011 (46 pages)

- I-200TS4 ver 0612 (32 pages)

- 10S (6 pages)

- 25D (12 pages)

- 35D (12 pages)

- I-180TS2 (33 pages)

- I-180TS2 (25 pages)

- 45 (15 pages)

- 450 (21 pages)

- 61D (13 pages)

- 70D (15 pages)

- 80D (16 pages)

- I-80 (20 pages)

- I-900 Ver 1-2007 (22 pages)

- I-900 Ver10-2008 (24 pages)

- I-110 (23 pages)

- I-110-SP (25 pages)

- I-110XL2 (33 pages)

- I-110TS (32 pages)

- I-110TS2 (23 pages)

- I-130 (28 pages)

- I-130-SP (21 pages)

- I-130TS2 (22 pages)

- I-130XL2 Ver 3-2007 (38 pages)

- I-130XL2 Ver 3-2009 (25 pages)

- I-140 (28 pages)

- I-150SP (24 pages)

- I-155-TS (51 pages)

- I-155XL (21 pages)

- I-155XL2 Ver 8-2006 (37 pages)

- I-155XL2 Ver 7-2008 (24 pages)

- I-160 (23 pages)

- I-160 XL (21 pages)

- CS18-HD (17 pages)

- I-175XL (23 pages)

- I-175XL2 (25 pages)