Sequence of operation – A.O. Smith TC-099 User Manual

Page 16

AOS WPC - Tech Training

15 of 72

Ashland City, TN © 2007

Servicing should only be performed by a Qualified Service Agent

VF BOILER SERVICE MANUAL

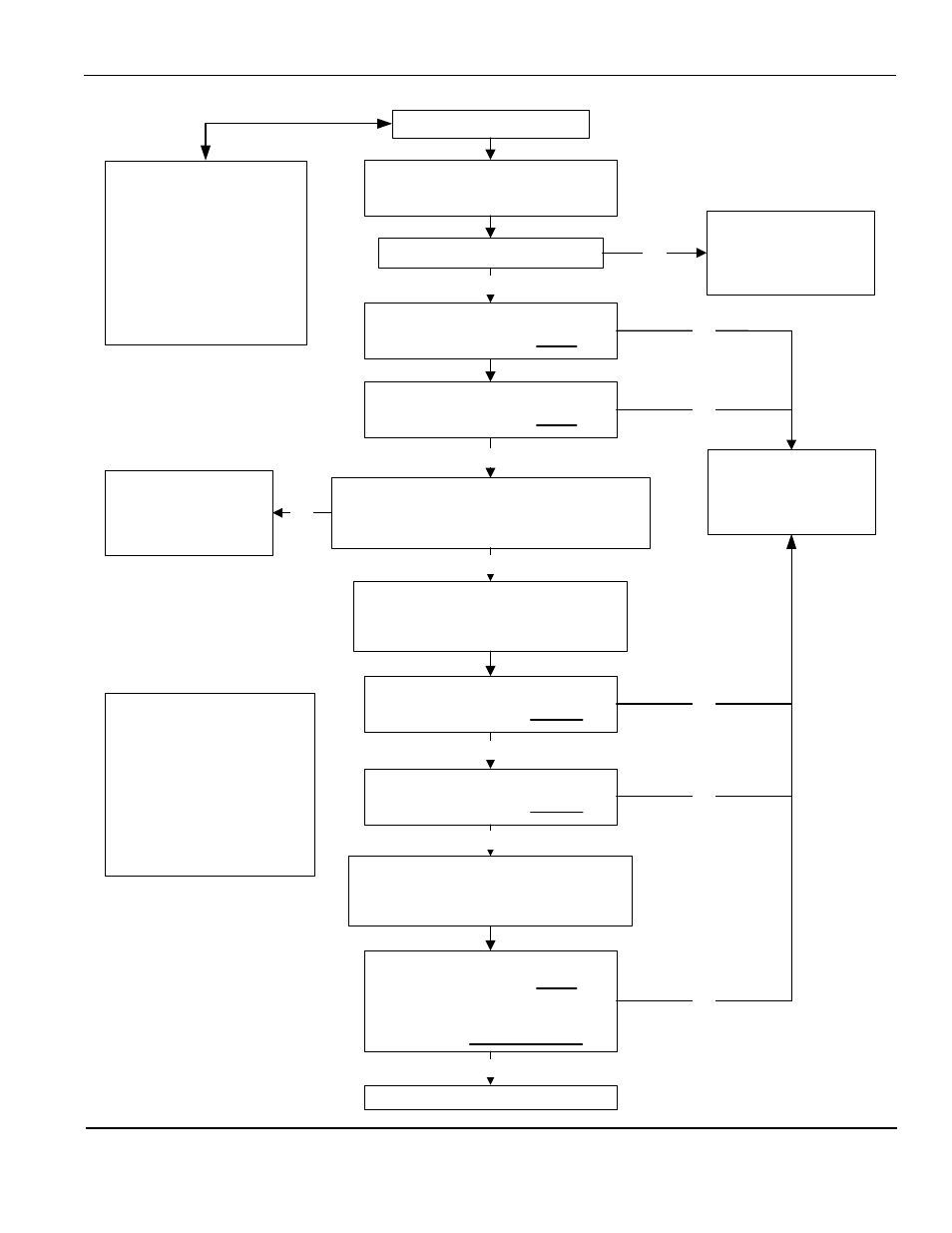

SEQUENCE OF OPERATION

MCB board applies power to pump relay

Pump Is Energized

Flow Switch Closes Contacts

NO

Boiler enters Service Mode

and locks out. UIM displays

No Flow

Error message

MCB Board

Closes VFD Enable/Disable Circuit

Sends 1-10 VDC Speed Instruction to VFD

Low Blower Prover Switch

Contacts Verified Open

YES

YES

NO

EMC 5000 Control System

compares the temperature read

from controlling probe (Inlet or

remote Tank/Loop) to the

Operating Set Point.

If the temperature read is less than

the Operating Set Point minus

Stage 1 Differential AND the

Enable/Disable (thermostat) circuit

is closed a call for heat is activated

Call For Heat is Activated

High Blower Prover Switch

Contacts Verified Open

Boiler enters Service Mode

and locks out. UIM displays

Blower Prov Stg1

Error message

NO

Blower Is Energized By VFD

Pre Purge State (approx 5000 rpm)

10-30 Seconds

Low Blower Prover Switch

Contacts Verified Closed

High Blower Prover Switch

Contacts Verified Closed

Boiler enters Service Mode

and locks out. UIM displays

Sequence Err

Error message

YES

YES

NO

NO

MCB Instructs VFD (1-10 VDC)

To Reduce Blower Speed

Ignition State (approx 2100 rpm)

High Blower Prover Switch

Contacts Verified Open

AND

Low Blower Prover Switch

Contacts Remain Closed

YES

YES

Next Page

NO

NOTE

The events shown in this flow chart

are in sequential order. The EMC

5000 is a multi-task control that

performs some functions

simultaneously. Only key events are

shown in order to provide a general

understanding of how the control

operates. Event timings can vary

depending on actual conditions.

NO